Jacket

A sheath and rack technology, applied in the field of welding cut protection device, can solve the problems of slow welding speed, scrapped products, and only small workshops, etc., and achieve the effect of satisfying various models, convenient operators, and good welding security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

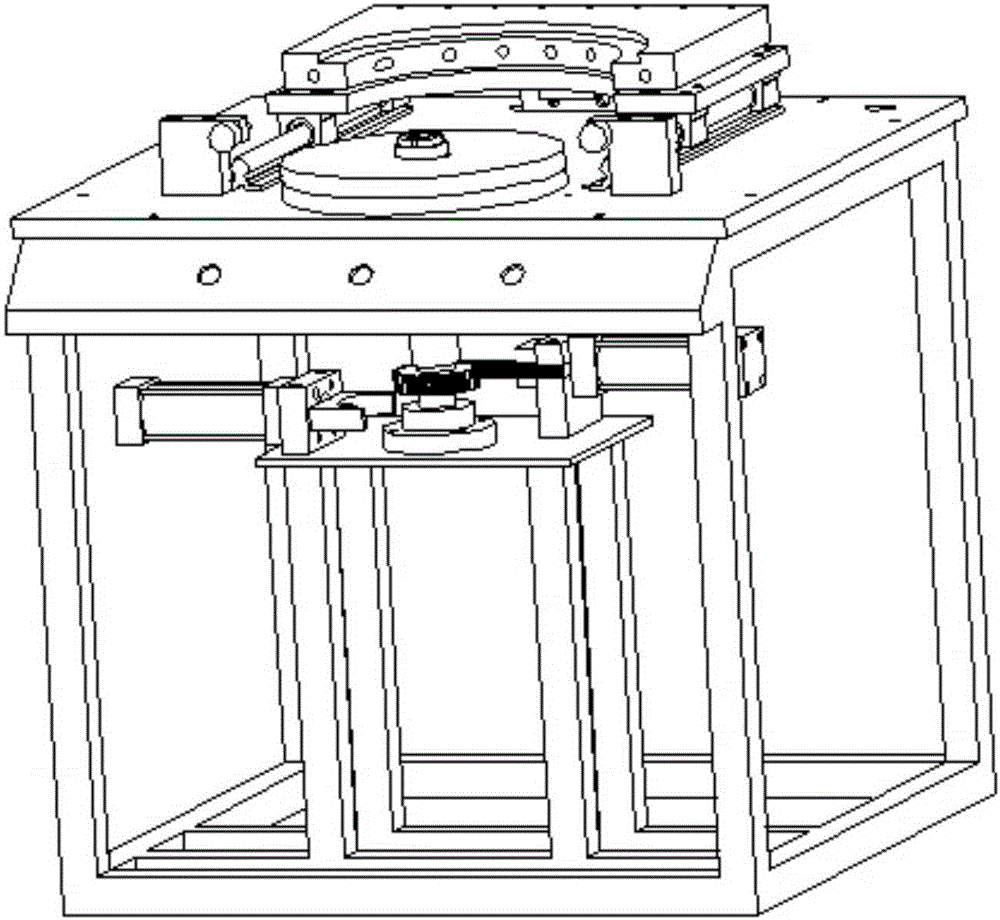

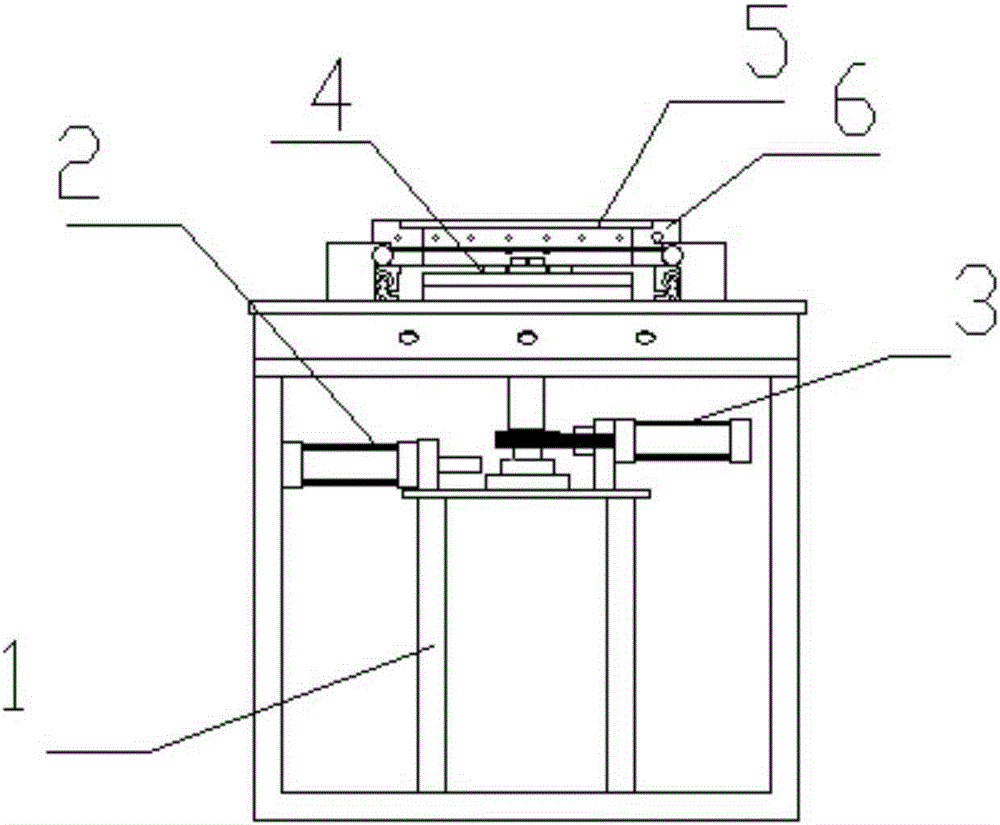

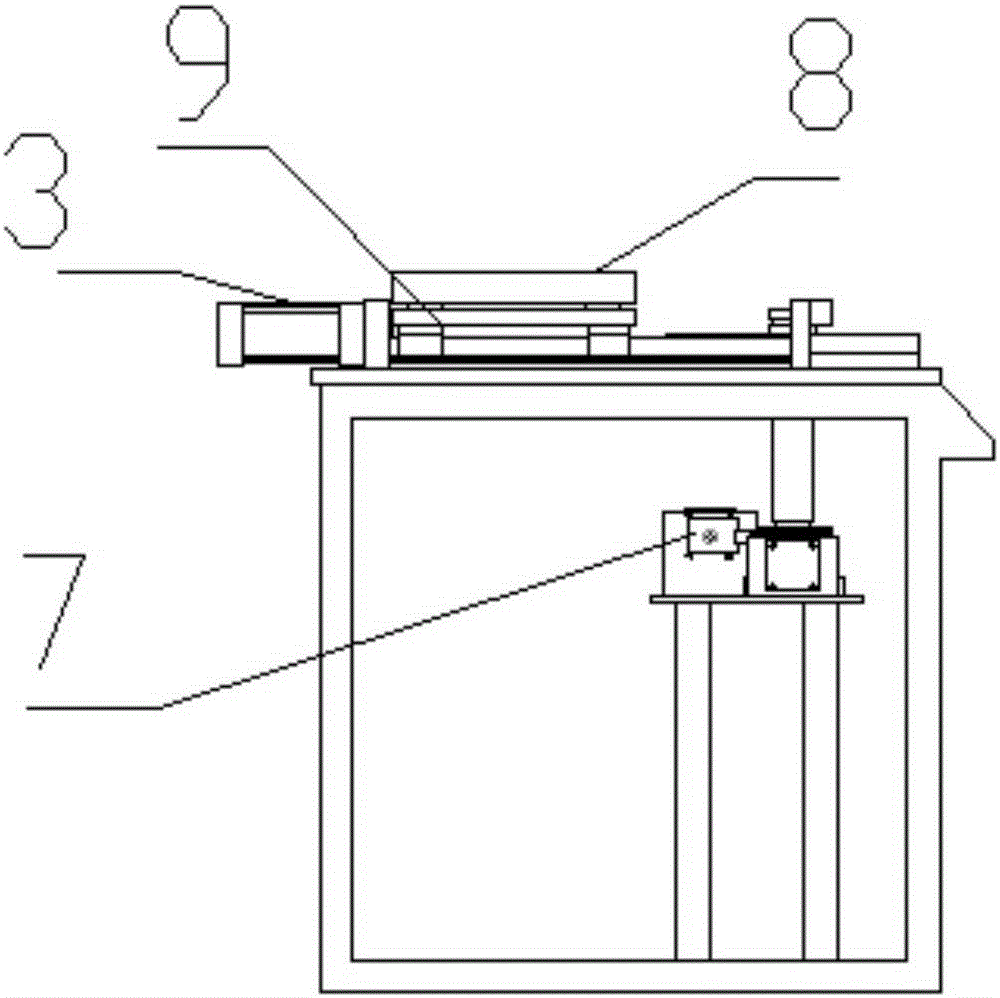

[0012] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a sheath includes a frame, on which a fixed cylinder, a push cylinder, and a push divider are arranged, a rotating disk is arranged on the top of the frame, a heating plate, a heat insulation plate, and a heating mold is arranged on the heating plate At the back of the rotating disc, there is a push cylinder, and a protective cover is placed on the place where the heating mold is placed.

[0013] The equipment is first started and preheated to the design temperature, and the product is put into the fixed supporting tooling to start. At this time, the heating plate automatically starts to move and exits after heating for a set time. Then the mold divider automatically rotates again, and then the heating plate starts again. Heating and exiting, then the tooling is automatically installed again, the heating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com