Tunnel maintenance platform

A platform and tunnel technology, which is applied in the field of railway tunnel maintenance and management, can solve problems such as large labor force, high cost, and slow speed, and achieve the effects of reducing labor intensity, improving work efficiency, and improving rock drilling progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

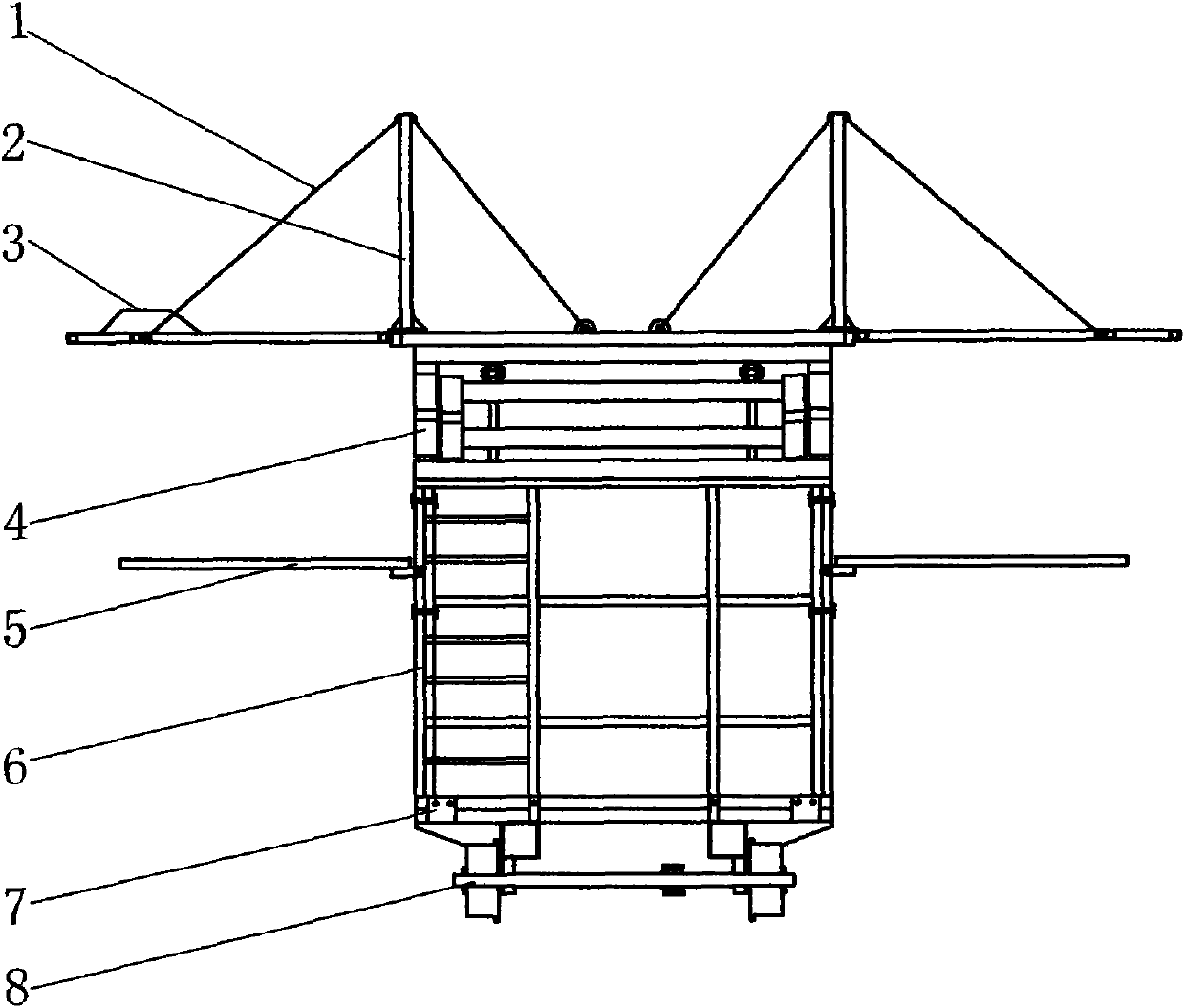

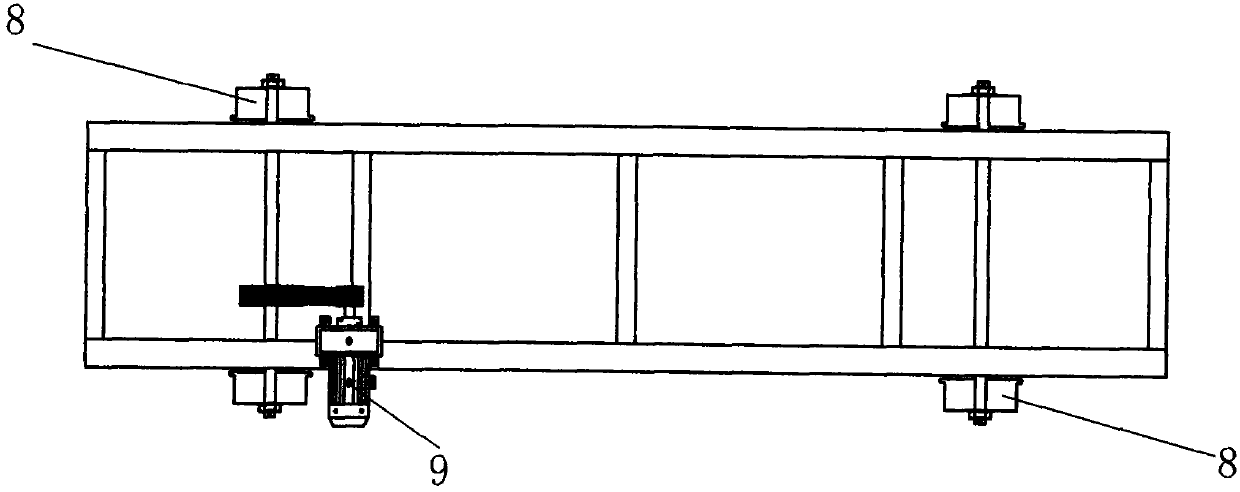

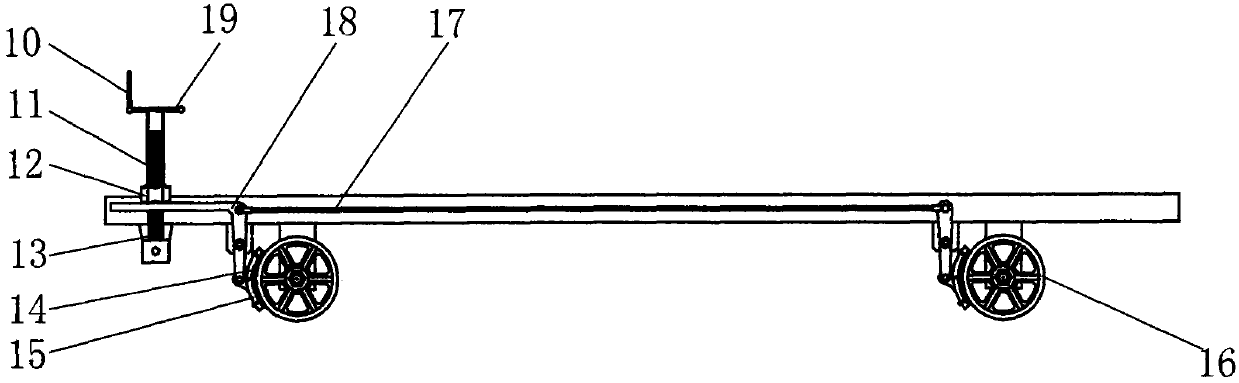

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, specifically referring to Figure 1 to Figure 6 :

[0028] The tunnel maintenance platform mainly includes a chassis part, a carriage part, an elevator part and equipment parts placed on the maintenance platform. The chassis part includes a transmission system and a braking system. The motor 9 and the rotating shaft arranged at the bottom of the chassis are composed of wheelsets 8 arranged at both ends of the rotating shaft. The brake system mainly consists of brake shoes 15, brake pads 14 arranged on the brake shoes, and brake cranks 18 connected to the brake shoes 15. , the rotary sleeve 11 connected to the brake crank 18 and the brake hand wheel 19; the compartment 6 is mainly composed of the compartment frame, the compartment door 23 and the compartment frame and the compartment panel; the lift 4 is mainly composed of the platform, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com