Self-propelled deep-purification farmland residual mulch recovery unit

A self-propelled, mulching technology, used in collectors, agricultural machinery and equipment, agricultural machinery and implements, etc., can solve the problem of increasing the difficulty of equipment design and the reliability of use, the new mulching film cannot reduce waste film, and cannot install multiple oil extraction machines. and other problems, to achieve the effect of high environmental adaptability, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The patent will be further described below in conjunction with the above-mentioned accompanying drawings as an example. The above-mentioned drawings used in the embodiment for illustration are only for illustration and should not be construed as a limitation to this patent; in order to better illustrate this embodiment, some parts of the drawings will be omitted, enlarged or reduced, and are not intended to It represents the size of the actual product; for those skilled in the art, it is understandable that some well-known structures and their descriptions in the drawings may be omitted.

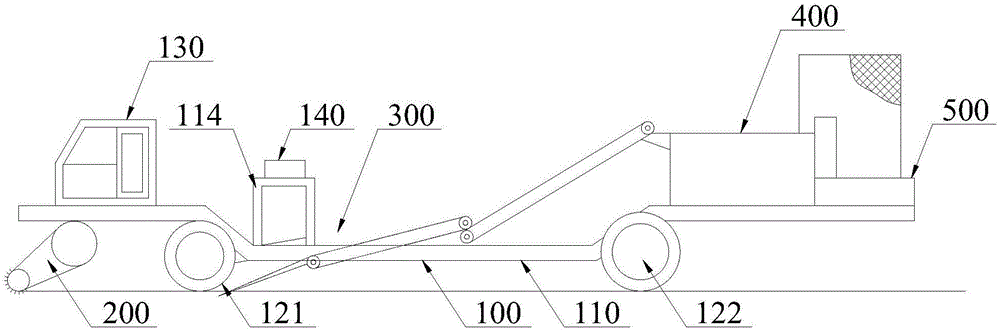

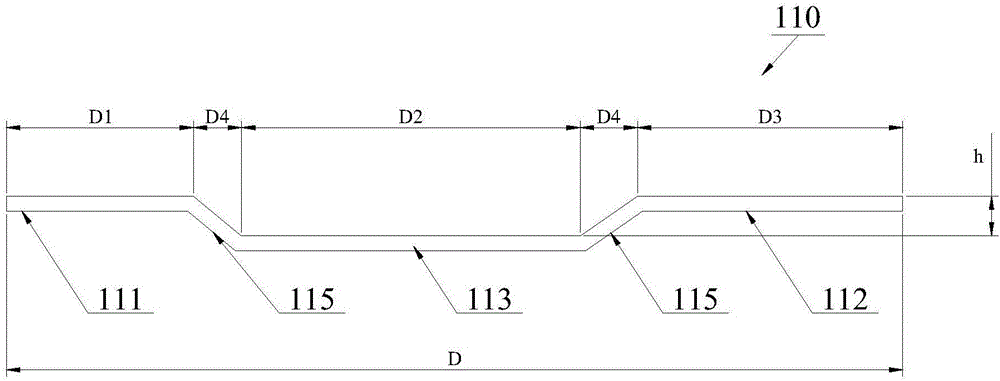

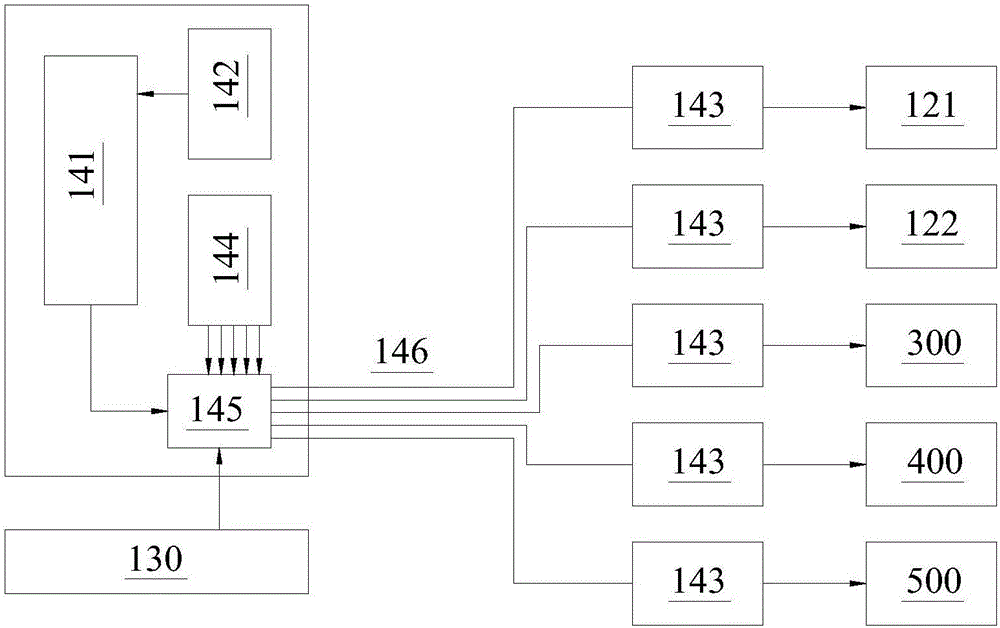

[0045] Such as figure 1 A self-propelled deep-layer purification of farmland residual mulch film recycling unit is shown, its structure includes: a body body 100; a rotary tillage system 200 for loosening the mulch film and soil. technology, its structure will not be further described; the conveying system 300 that scoops up and transports the loosened mulch and soil; the separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com