Artificial prosthesis and preparation method thereof

An artificial prosthesis and prosthesis technology, applied in the direction of additive processing, etc., can solve problems such as restricting application, and achieve the effect of improving efficiency, eliminating low efficiency and high cost, and eliminating dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Aiming at the problems existing in the prior art, the invention provides a kind of preparation method of artificial prosthesis, comprises the steps:

[0062] S1: Design the prosthesis by 3D software to obtain a digital prosthesis model, the digital prosthesis model has the same shape parameters as the designed prosthesis;

[0063] S2: Using a digital 3D printer to integrally print the digital prosthesis model obtained in step S1 to obtain a prosthesis body;

[0064] S3: removing the adhesive on the prosthesis body, cleaning and drying the prosthesis body;

[0065] S4: Sintering the dried prosthesis body obtained in step S3 to obtain a preformed prosthesis;

[0066] S5: Post-processing the preformed prosthesis to obtain a shaped prosthesis.

[0067] Further in the above technical solution, in step S1, the digital prosthesis model has shape parameters consistent with the designed prosthesis, specifically including:

[0068] The digital prosthesis model has the same sha...

Embodiment 2

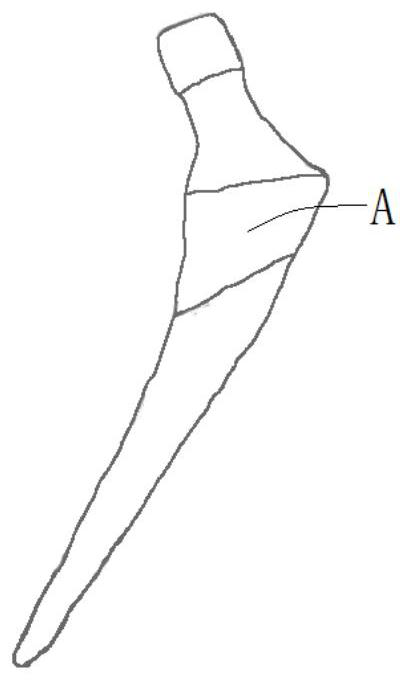

[0094] Utilize the preparation method described in the present invention to prepare the artificial joint stem on the bone length:

[0095] The most common modern artificial joint without bone cement fixation stem consists of two to three basic parts:

[0096] One is the main structural part initially formed by forging;

[0097] The second is that the rough surface bone formed by thermal spraying or plasma spraying technology grows into the metal interface A. The thickness of this interface A is generally 0.5-2.0mm. parts above the end, such as figure 1 shown;

[0098] The third is that for products with certain biological activity and fixation, a layer of hydroxyapatite coating can also be coated on the metal coating by thermal spraying or plasma spraying.

[0099] Due to the high requirements on the fatigue strength of the joint handle and its large size, there are currently no products made by selective laser or electron beam fusion 3D printing technology on the market. T...

Embodiment 3

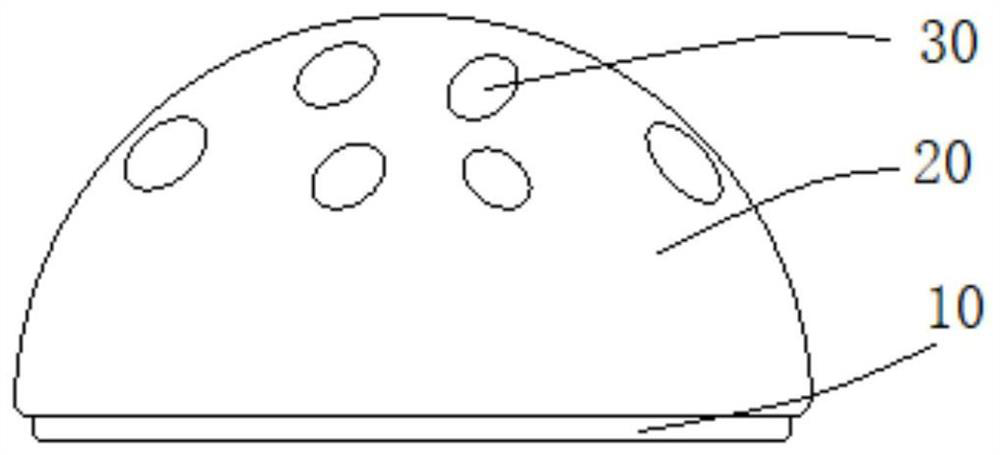

[0112] Utilize the preparation method described in the present invention to prepare the bone-in-growth artificial joint acetabular cup:

[0113] Modern artificial hip acetabular cups have basically adopted the form of non-cemented biological fixation. The acetabular cup is mainly composed of two parts:

[0114] One is the main structure part without holes, which is the main body 10 of the acetabular cup,

[0115] The second is the outer surface 20 that contains porous structure to form a biological fixation with the host bone, such as figure 2 As shown, there are a number of holes 30 on the outer surface.

[0116] Traditional preparation methods for acetabular cups include:

[0117] 1. Prepare the main body 10 of the acetabular cup by machining;

[0118] Two, a porous "pearl face" or mesh is bonded to the outer surface 20 of the main body by a sintering process.

[0119] Modern selective laser or selective electron beam fusion 3D printing technology has been successfully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com