Hollow single-arc-shaped small window frame limestone powder line

A window covering line and arc technology, applied in the field of single-arc small window covering stone powder line, can solve the problems of easy falling off and not resistant to water immersion, high price, color difference affecting appearance, etc., to achieve wear resistance and imitation, reduce Weight, the effect of avoiding the risk of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

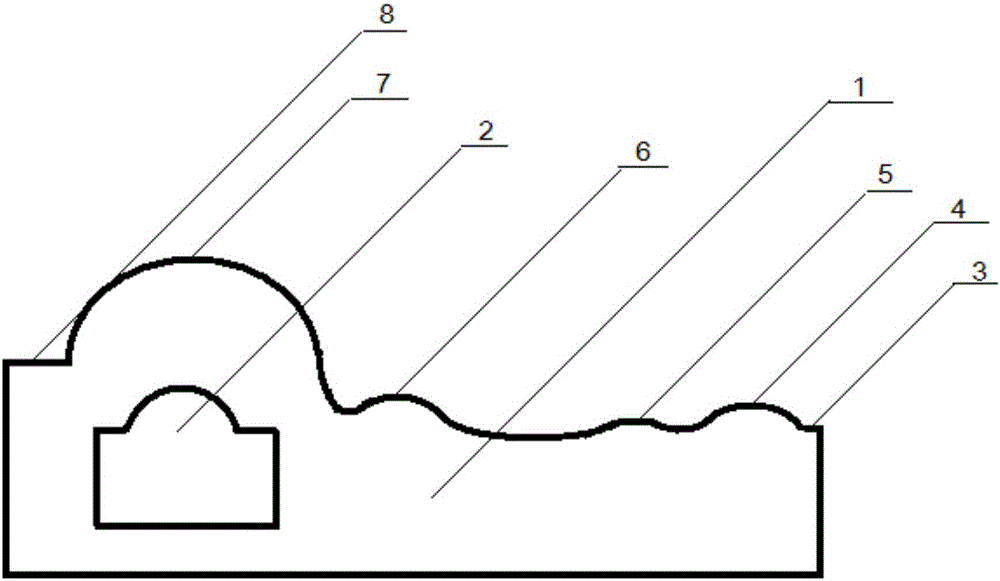

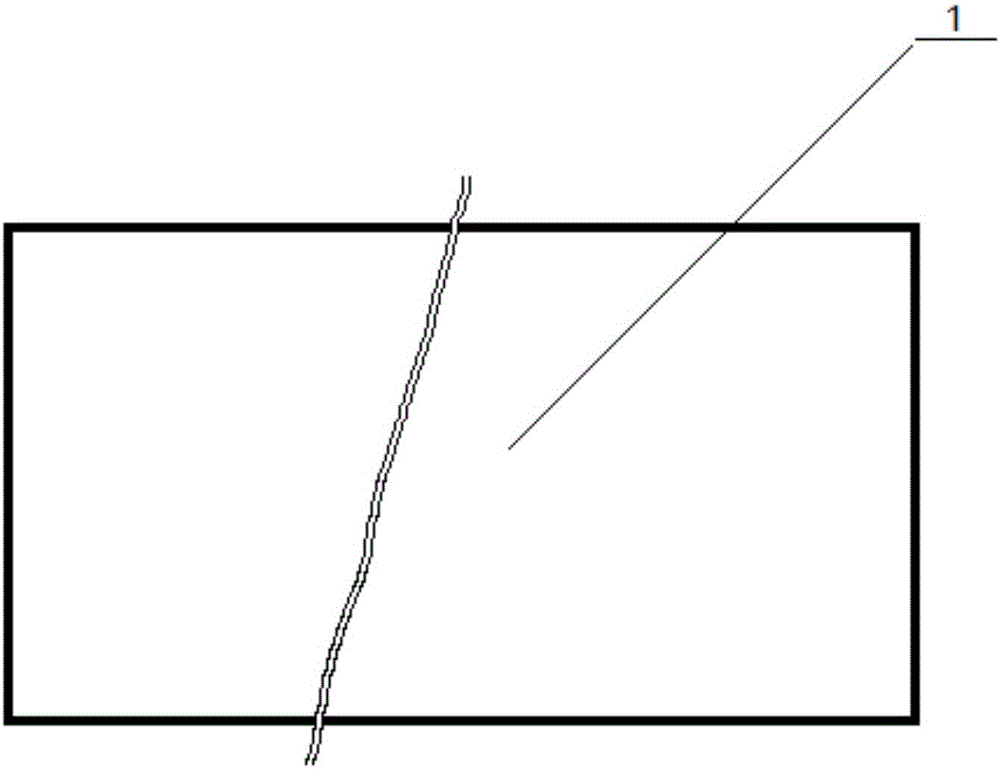

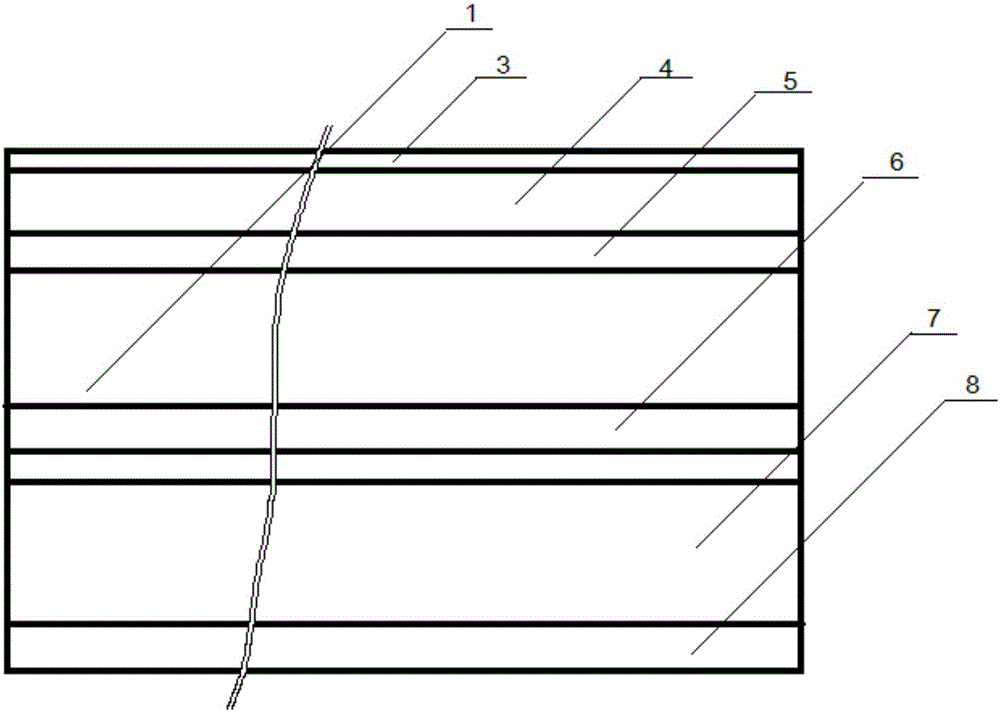

[0017] Embodiment 1: A hollow single-arc small window cover with stone powder lines, the window cover line body 1 is a slender strip shaped by pressing stone powder, and the cross-sectional shape of the window cover line body 1 is an arc on the upper left side and a rectangular shape on the lower part. Shape; the inside of the window cover line body 1 is provided with holes for heat insulation and material saving; the top of the window cover line body 1 is sequentially arranged from right to left, the right platform 3, the right side protrusion 4, and the right side small Protrusion 5, left protrusion 6, large circular arc protrusion 7 and left platform 8; a left large hole 2 is provided at the corresponding place under the large circular arc protrusion 7, and the surface of the window casing line body 1 is sequentially provided with Pattern layer, primer protection layer and wear layer.

Embodiment 2

[0018] Embodiment 2: A hollow single-arc small window cover with stone powder lines, the window cover line body 1 is a slender and long strip pressed by stone powder, and the cross-sectional shape of the window cover line body 1 is an arc-shaped lower part on the upper left. Shape; the inside of the window cover line body 1 is provided with holes for heat insulation and material saving; the top of the window cover line body 1 is sequentially arranged from right to left, the right platform 3, the right side protrusion 4, and the right side small Protrusion 5, left protrusion 6, large circular arc protrusion 7 and left platform 8; a left large hole 2 is provided at the corresponding place under the large circular arc protrusion 7, and the surface of the window casing line body 1 is sequentially provided with Pattern layer, primer protection layer and wear layer. The bottom of the window casing line body 1 is provided with small convex grooves for increasing the area for applying...

Embodiment 3

[0019] Embodiment 3: A hollow single-arc small window cover with stone powder lines, the window cover line body 1 is a slender strip shaped by pressing stone powder, and the cross-sectional shape of the window cover line body 1 is an arc-shaped lower part on the upper left. Shape; the inside of the window cover line body 1 is provided with holes for heat insulation and material saving; the top of the window cover line body 1 is sequentially arranged from right to left, the right platform 3, the right side protrusion 4, and the right side small Protrusion 5, left protrusion 6, large circular arc protrusion 7 and left platform 8; a left large hole 2 is provided at the corresponding place under the large circular arc protrusion 7, and the surface of the window casing line body 1 is sequentially provided with Pattern layer, primer protection layer and wear layer. The bottom of the window casing line body 1 is provided with small convex grooves for increasing the area for applying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com