Damping Forced Positioning Mechanism of Furniture Turning Device

A technology of turning device and positioning mechanism, which is applied in the direction of building construction, switches with braking devices, door/window accessories, etc. It can solve the problem that the buffer damping force does not have the adjustment function, cannot meet the needs of use, and cannot achieve uniformity, etc. problems, to achieve the effect of small collision, stable work and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

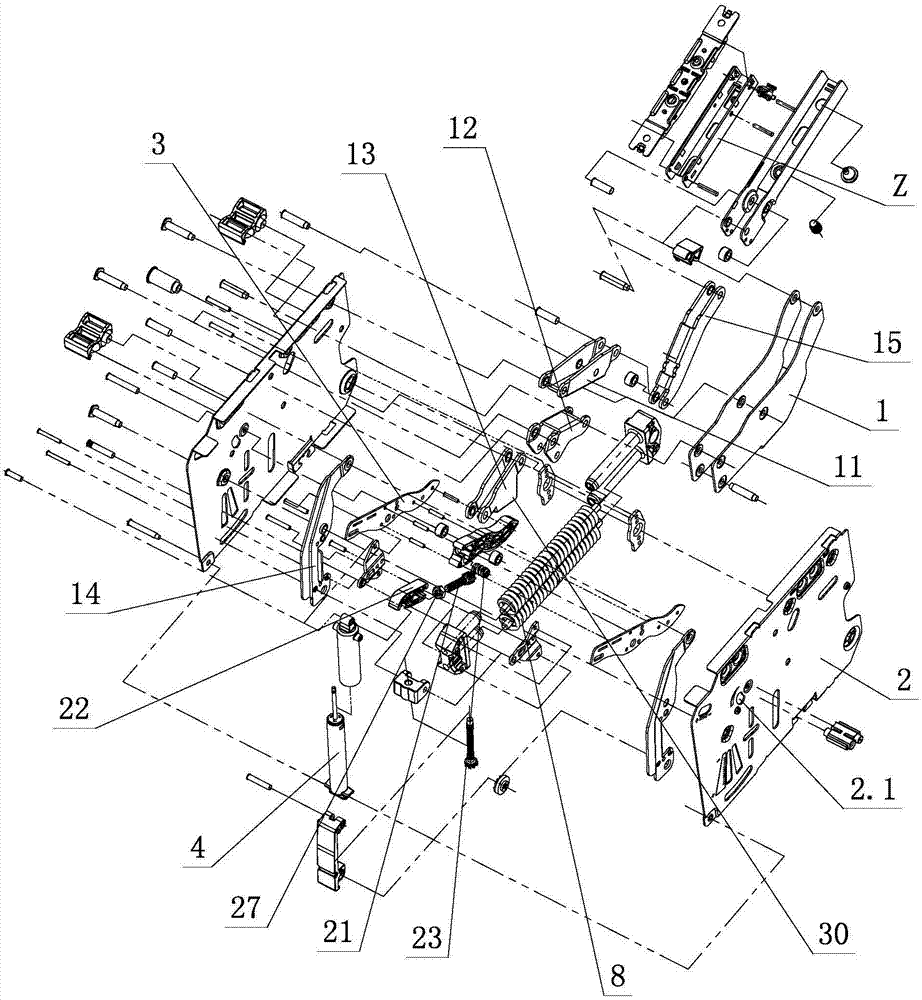

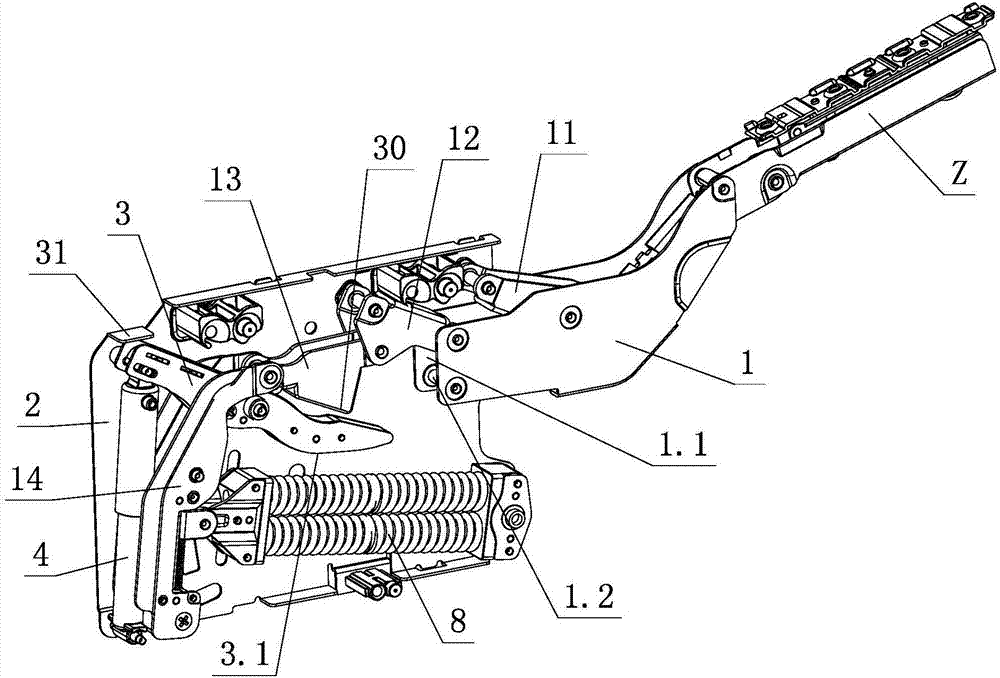

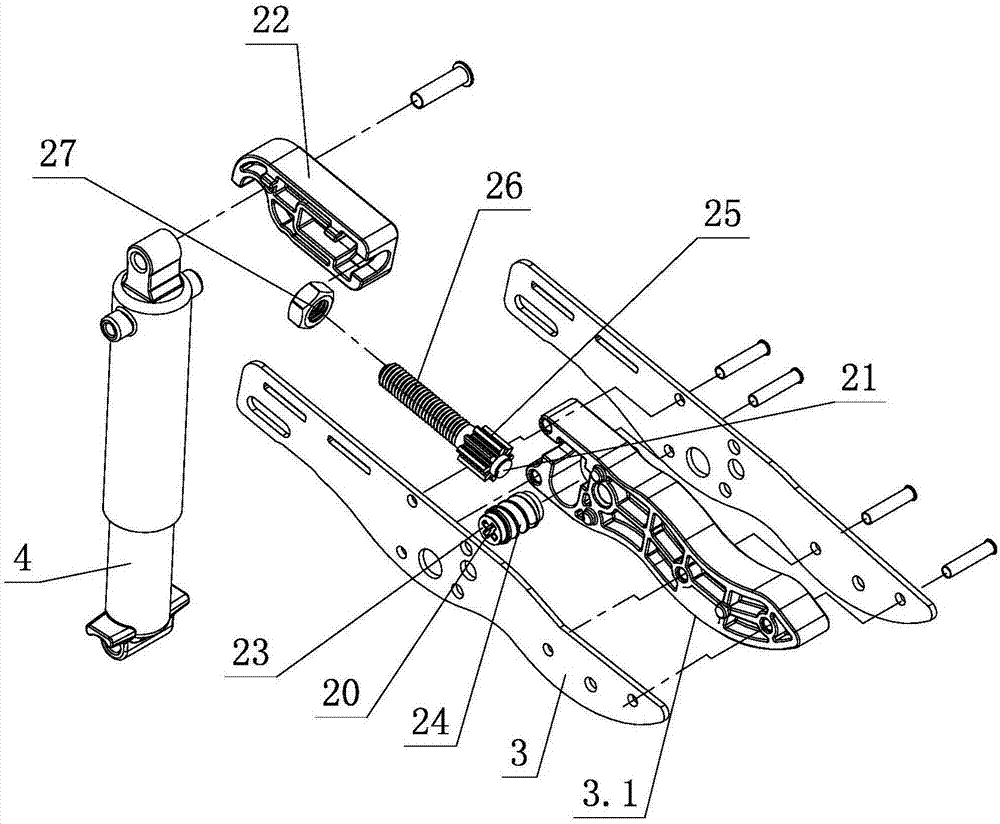

[0030] see Figure 1-Figure 6 , the damping forced positioning mechanism of the furniture overturning device includes a push element 1, a connecting arm assembly and a fixed element 2, the push element 1 is hinged to the fixed element 2 through the connecting arm assembly, an elastic assembly is arranged on the fixed element 2, and the push element 1 The elastic component is elastically flipped open and closed on the fixed element 2, and also includes a lever element 3 and a damper 4. The lever element 3 is rotatably arranged on the fixed element 2, and one end interacts with the damper 4, and the other end is at least on the push element 1. It interacts with the pushing element 1 when flipping and closing a stroke; the connecting arm assembly is provided with a connecting arm positioning part 30 .

[0031] When the push element 1 is flipped and closed relative to the fixed element 2 for at least a certain stroke, the end of the lever element 3 is in contact with the push elem...

no. 2 example

[0047] see Figure 7-Figure 10 , the damping forced positioning mechanism of the furniture turning device is different from the first embodiment in that the connecting arm assembly at least includes a first connecting arm 11, a second connecting arm 12 and a third connecting arm 13, and the first connecting arm 11 The second connecting arm 12 is hinged with the pushing element 1, the fixing element 2 and the third connecting arm 13 respectively; the second connecting arm 12 is provided with a connecting arm locator 33, and the connecting arm is positioned One end of piece 33 is rotatably arranged on the fixed element 2, the middle part is slidably arranged on the second connecting arm 12, and is interlocked with the second connecting arm 12. There is a fixed positioning part 31 on it; when the idle section of the lever element 3 and the action part 1.2 of the push element 1 are in the initial contact state, the connecting arm positioning part 30 and the fixed positioning part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com