Interconnected commutated board card integration and heat dissipation integrated control box

A technology of control boxes and boards, which is applied in connection, cooling/ventilation/heating transformation, coupling devices, etc., which can solve the problem of affecting the stability of signal external interconnection transfer performance, the liquid-cooled cold plate cannot dissipate heat from the back of the device, and the circuit board cannot be solved. Problems such as double-sided heat dissipation, to solve the problem of double-sided heat dissipation, simple structure, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

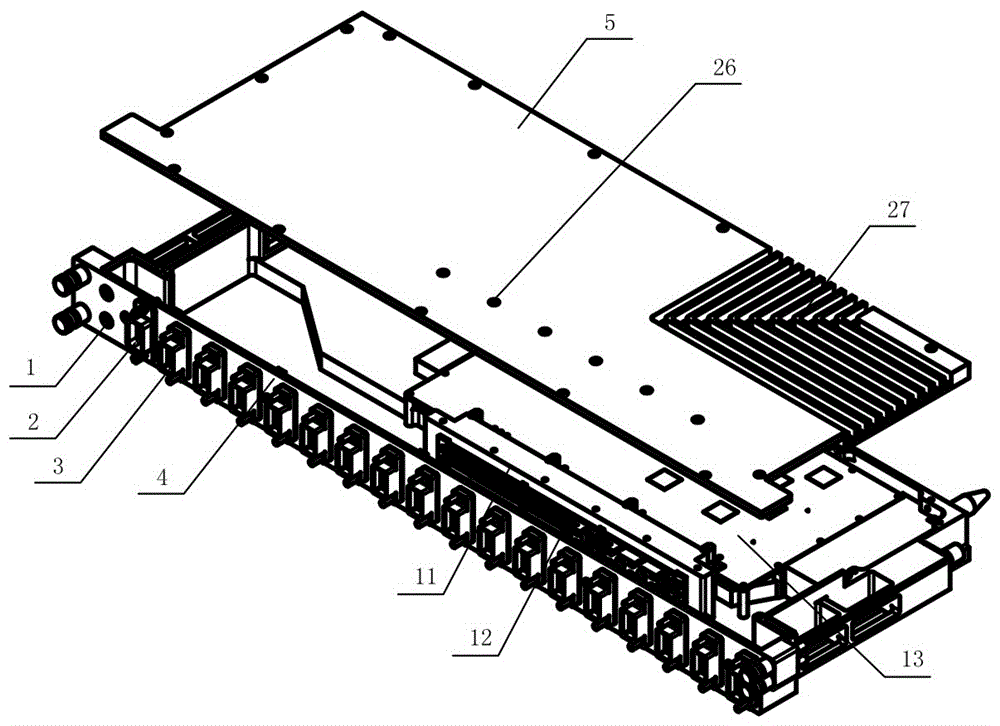

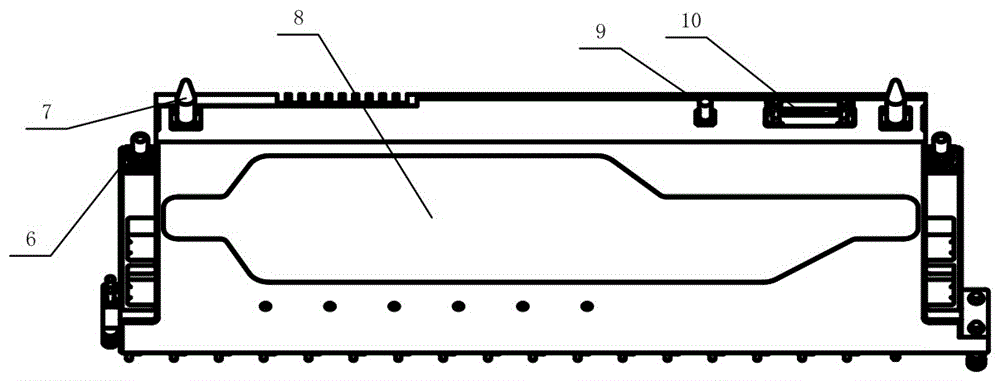

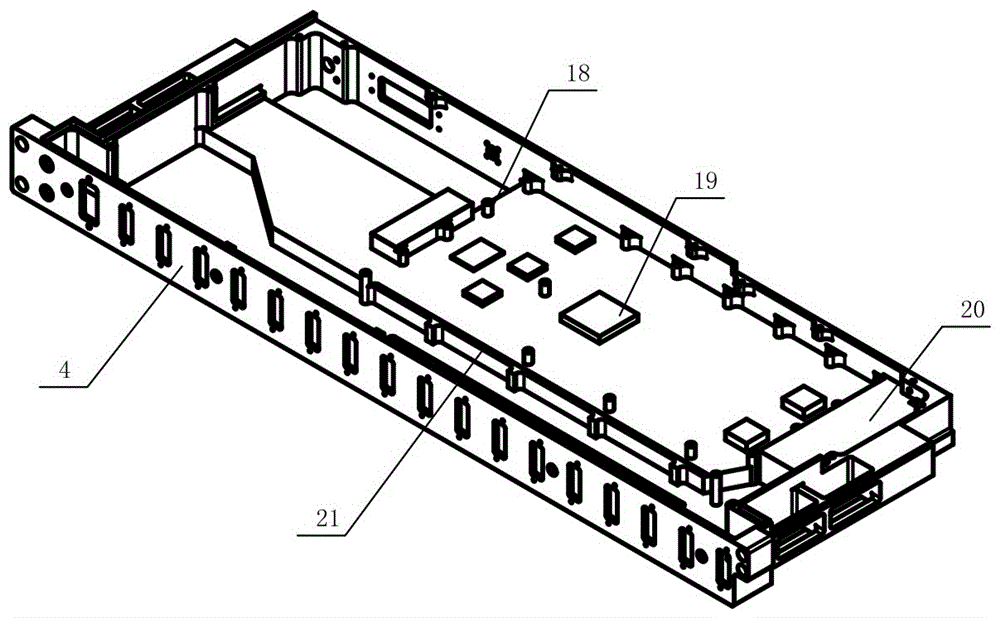

[0011] See attached figure 1 ~ attached figure 2 , the present invention is composed of a box body 4, a cooling cover plate 5, a liquid cooling cover plate 8 and a circuit board 13, and the circuit board 13 is arranged in the box body 4 provided with a liquid cooling flow channel 22 and a liquid cooling fin 23 and consists of The cooling cover plate 5 and the liquid cooling cover plate 8 are packaged into a heat dissipation integrated control box; the outer sides of the box body 4 are respectively provided with an indicator light 1, a power connector 2, a photoelectric hybrid connector 3, and a fluid connector 6 , guide post 7, radio frequency connector 9, comprehensive mixed connector 10, LRM connector mounting bracket 11 and LRM connector socket 12; the indicator light 1 is used for power supply indication and working status indication of the entire product; The power connector 2 is used to supply power to the circuit board 13; the photoelectric mixed connector 3, the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com