Permanent magnetic multi-phase dipolar high speed motor

A high-speed motor, two-pole technology, applied to synchronous motors with stationary armatures and rotating magnets, the shape/style/structure of winding conductors, etc., can solve problems such as multi-energy-consuming motors, heat generation, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

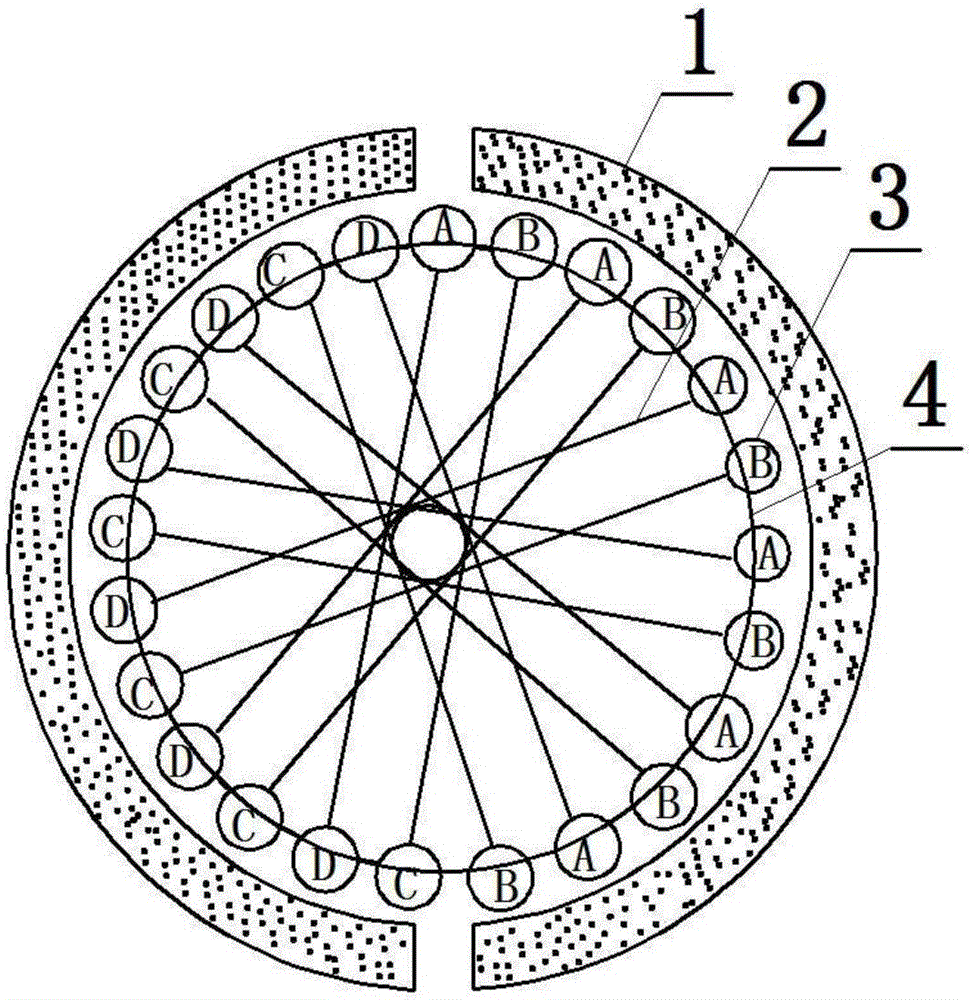

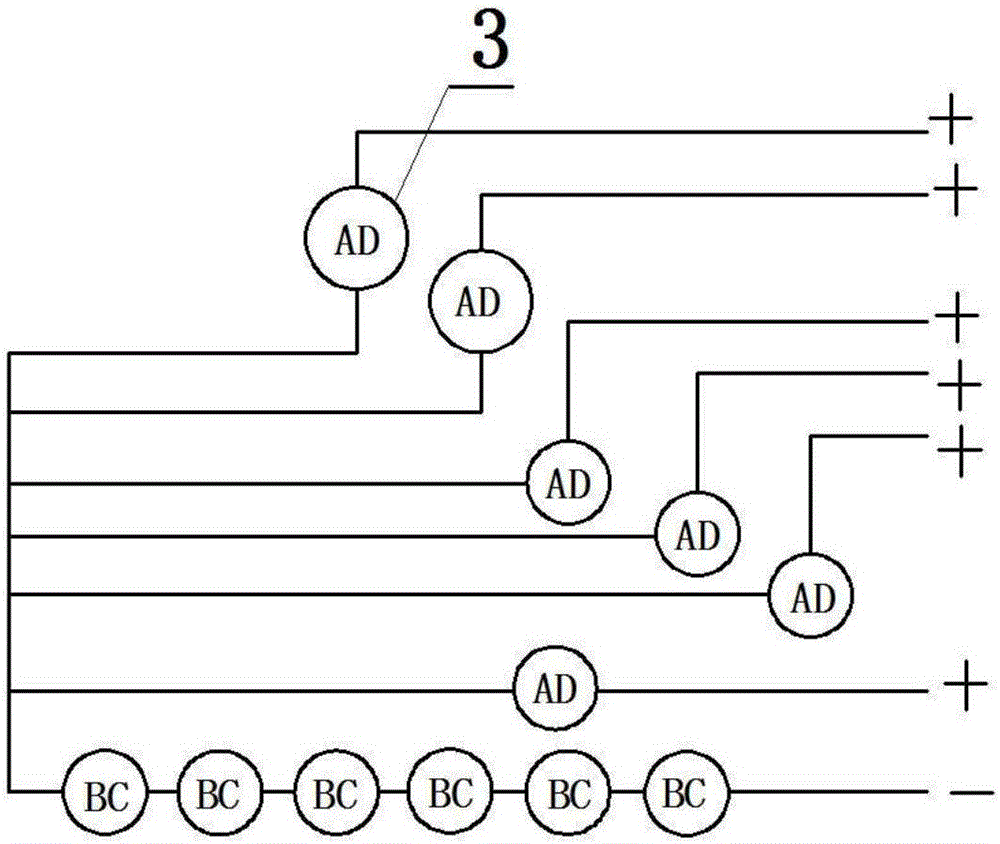

[0010] Permanent magnet multi-phase two-pole high-speed motors can be divided into five-phase, seven-phase, nine-phase..., this application takes seven-phase as an example to illustrate: In the figure, the permanent magnet multi-phase two-pole high-speed motor includes: ring magnet 1, The winding group connection wire 2, the winding group 3, the high-permeability magnet 4; the permanent magnet multi-phase two-pole high-speed motor has a ring magnet 1, which is the outer rotor, and the ring magnet 1 is placed with a ring-shaped high-permeability magnet 4, which is the stator, and the high-conductivity There is a groove on the magnet 4, and the winding group 3 is placed in the groove; the winding group 3 on the left side of the high-permeability magnet 4 is the winding group C3 and the winding group D3 are arranged crosswise, and the winding group 3 on the right side The winding group A3 and the winding group B3 are arranged to cross each other; the winding group C3 and the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com