Device and method for printing large titanium alloy part through laser coaxial fuse

A titanium alloy and laser technology, applied in the direction of additive manufacturing, additive processing, etc., can solve problems such as constraints, achieve high material utilization, realize free manufacturing, and reduce production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

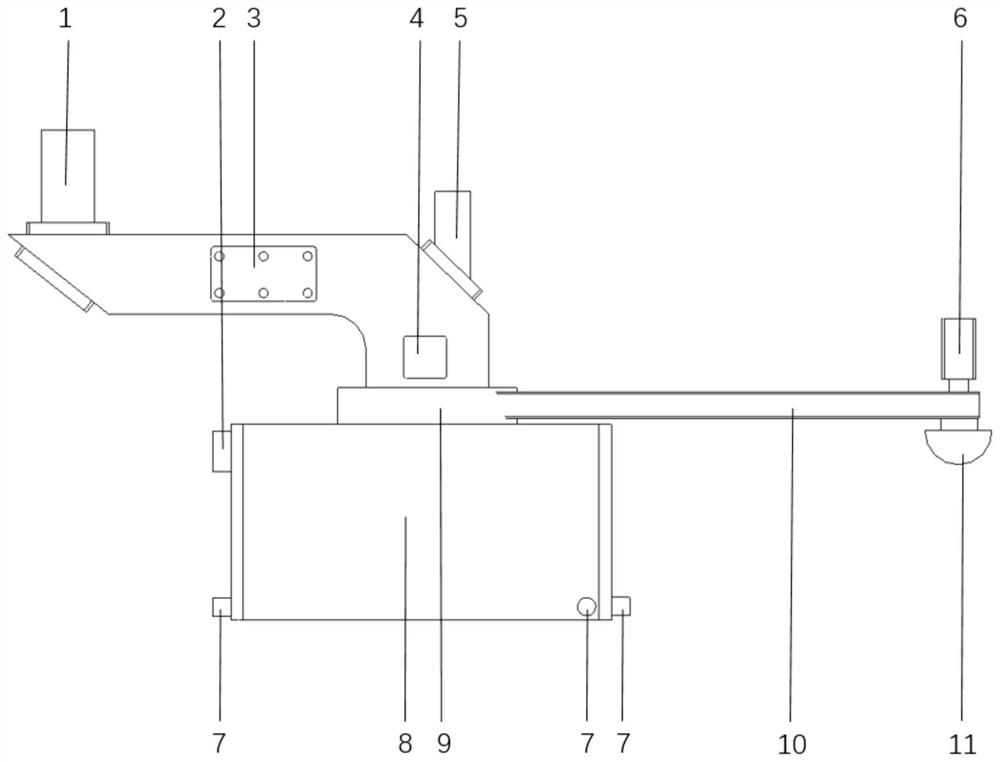

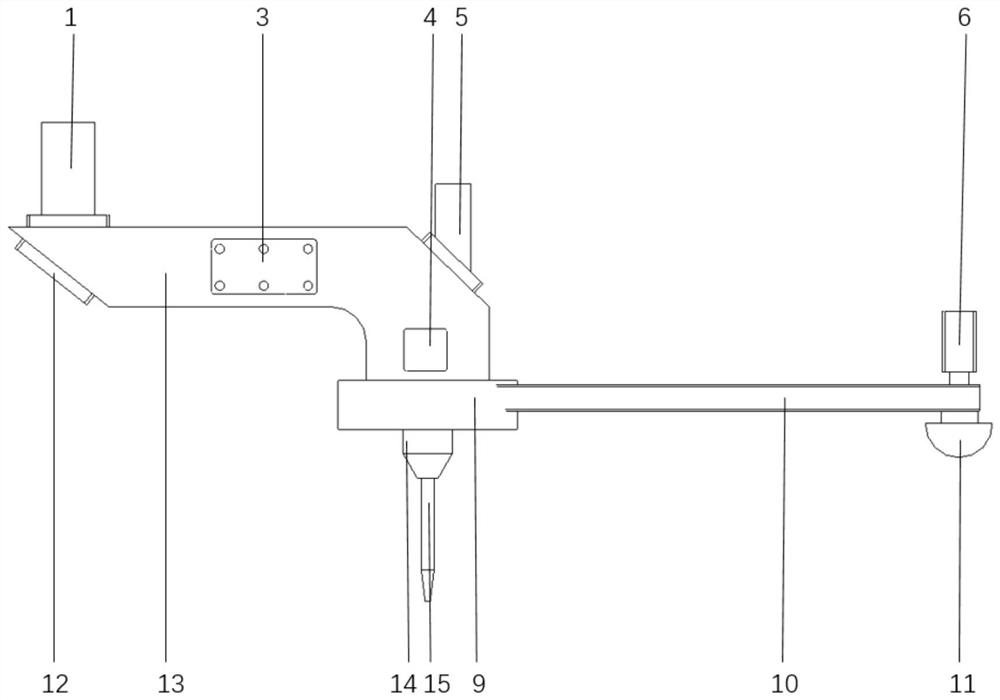

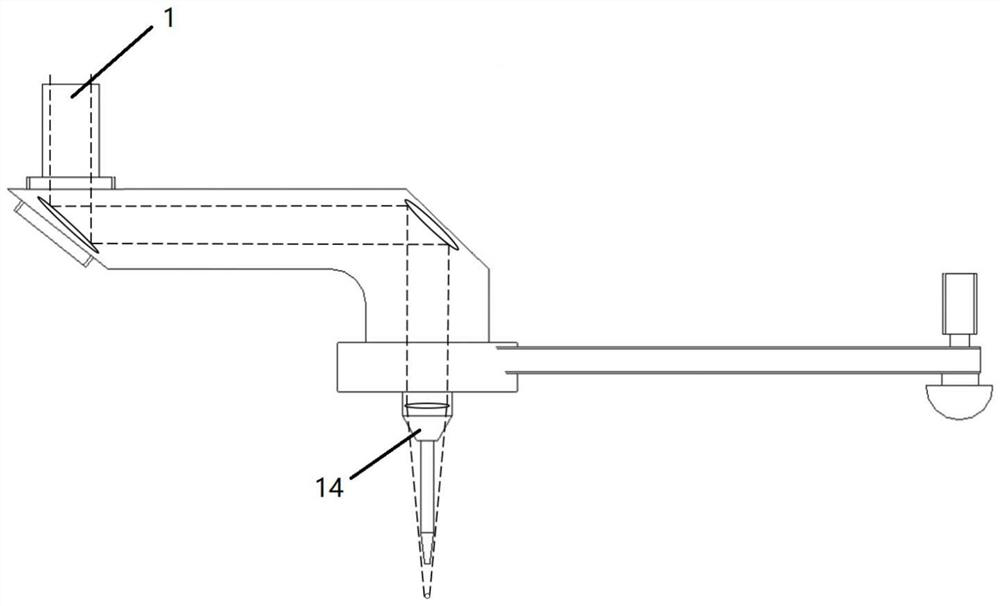

[0037] Firstly, the optical fiber is inserted into the laser adapter 13 by the optical fiber connector 1. After being reflected by the internal optical path, it is emitted by the optical mirror 14 to form a ring-shaped spot focused on the bottom 10 mm of the wire feeder 15. The energy generated by the laser focus is used to melt the wire for additive manufacturing. The wire is sent into the laser through the wire feeder from the wire feeder joint 5 through the wire feeder 15 to realize coaxial wire feeding in the laser. The optical fiber of the laser cleaning equipment is connected to the laser adapter 13 by the laser cleaning fiber connector 12 and connected to the laser cleaning head 11 for laser cleaning, wherein the first stepper motor 4 can control the rotary table 9 to rotate in any direction in the X-Y plane for laser cleaning , the second stepping motor 6 can drive the laser cleaning head 11 to move radially along the moving guide rail 10 to ensure the laser cleaning ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com