Preparation method of fiber-toughened SiC ceramic-based composite material three-dimensional member

A three-dimensional component and fiber toughening technology, applied in the field of complex component preparation, can solve the problems of limited use temperature, restricted engine performance, and high density, and achieve the effects of improving wettability, improving thrust-to-weight ratio, high temperature performance, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

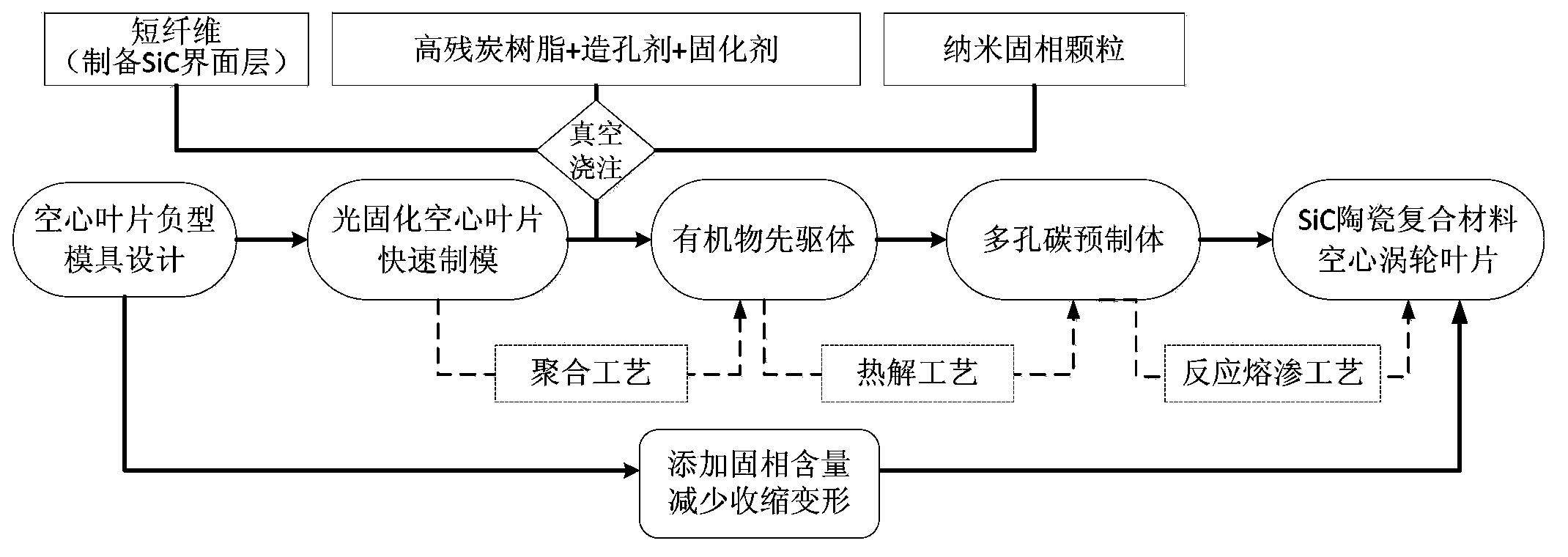

[0045] see figure 1 , the preparation method of fiber toughened SiC ceramic matrix composite material hollow turbine blade, comprises the following steps:

[0046] 1. Hollow blade negative mold design

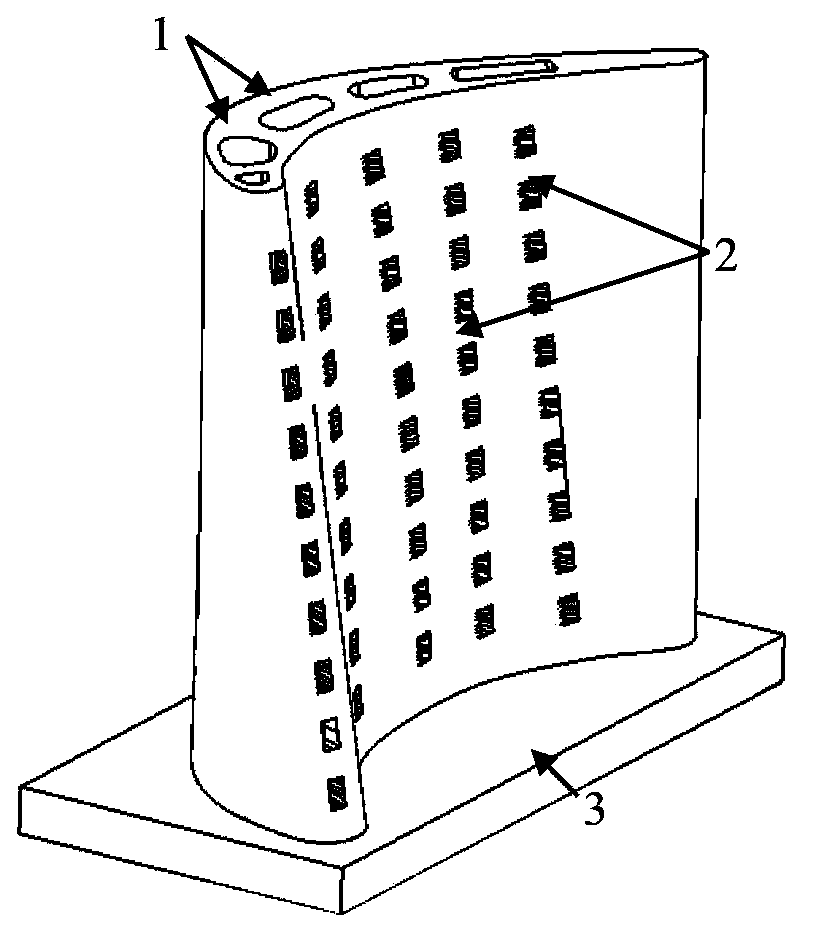

[0047] 1.1 Use UG software to build a hollow blade model, such as figure 2 As shown, 1 is the cooling channel; 2 is the special-shaped air film hole; 3 is the edge plate. Then convert the 3D model into STL format data and save it.

[0048] 1.2 Use the layered software Magics to process the 3D model layered and design the support, and import the processed data into the manufacturing system of the light-curing rapid prototyping machine.

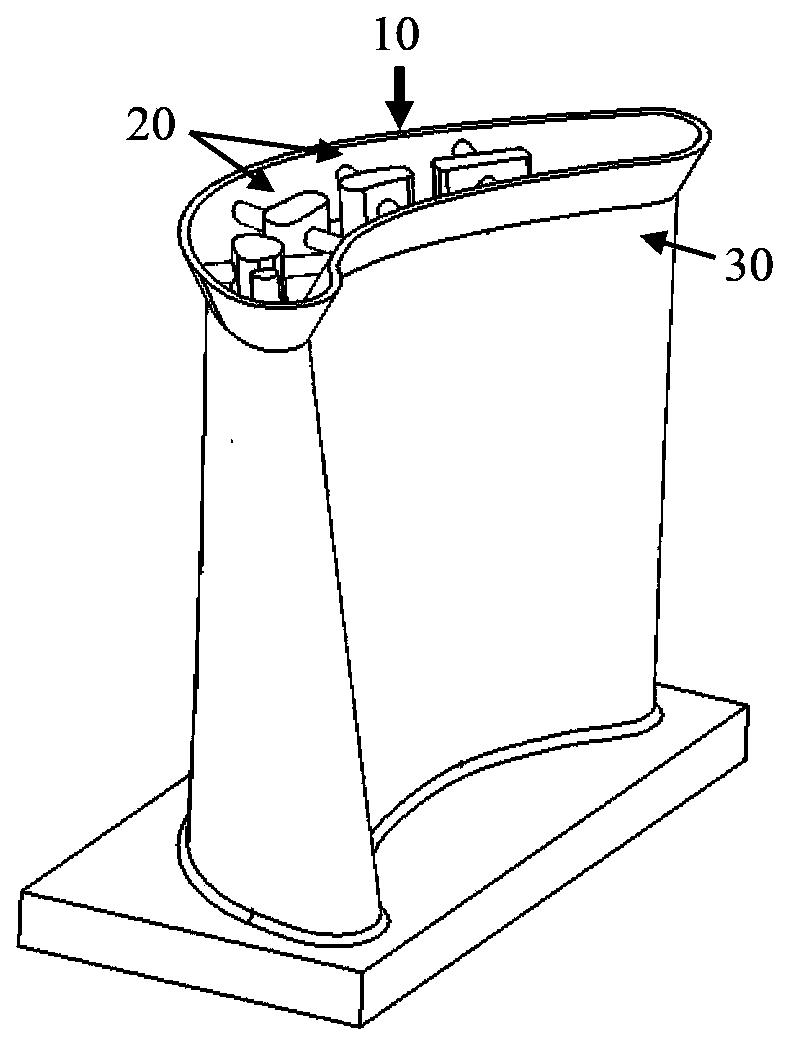

[0049] 1.3 Using light curing rapid prototyping technology to manufacture the negative mold of the hollow blade, such as image 3 As shown, 10 is the gate; 20 is the core; 30 is the shell.

[0050] 2. Add pore forming agent

[0051] Mix liquid phenolic resin (type 2130) and pore-forming agent ethylene glycol according to the mass ratio of 5...

Embodiment 2

[0076] see figure 1 , the preparation method of fiber toughened SiC ceramic matrix composite material hollow turbine blade, comprises the following steps:

[0077] 1. Hollow blade negative mold design

[0078] 1.1 UG software is used to construct the hollow blade model, and then the three-dimensional model is converted into STL format data for storage.

[0079] 1.2 Use the layered software Magics to process the 3D model layered and design the support, and import the processed data into the manufacturing system of the light-curing rapid prototyping machine.

[0080] 1.3 Using light-curing rapid prototyping technology to manufacture the negative mold of the hollow blade.

[0081] 2. Add pore forming agent

[0082] Mix the liquid phenolic resin (type 2130) and the pore-forming agent ethylene glycol according to the mass ratio of 50:70~85 and mix evenly. By changing the amount of pore-forming agent added, the microstructure (porosity, pore size distribution, and pore wall thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com