A non-isolated inverter for suppressing ripple and its control method

A control method and isolation technology, applied in control/regulating systems, instruments, regulating electrical variables, etc., can solve the problems of large inductance and capacitance, poor practicability, complex control algorithms, etc., to suppress low-frequency current ripple, extend Service life, the effect of small decoupling capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

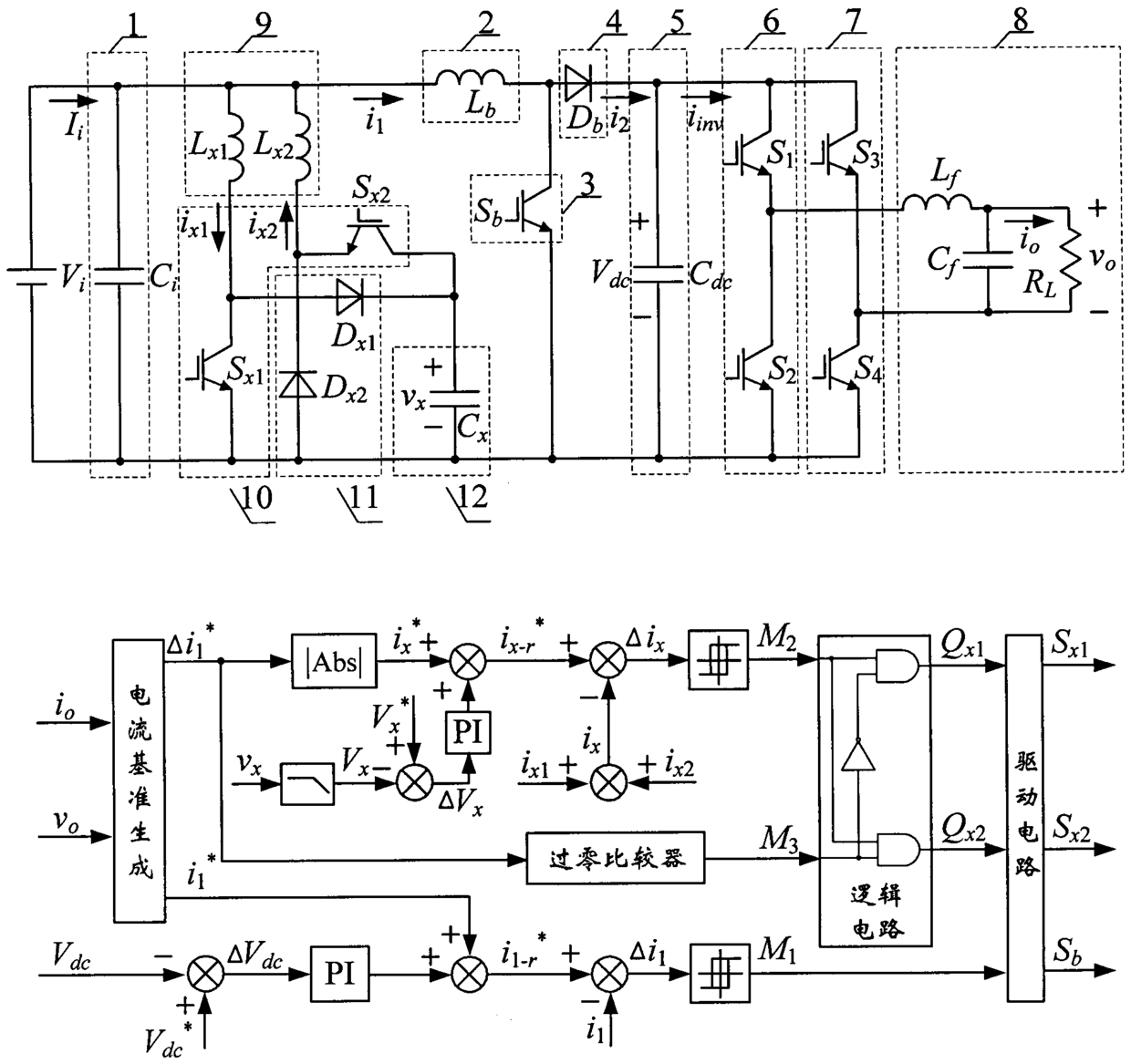

[0034] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

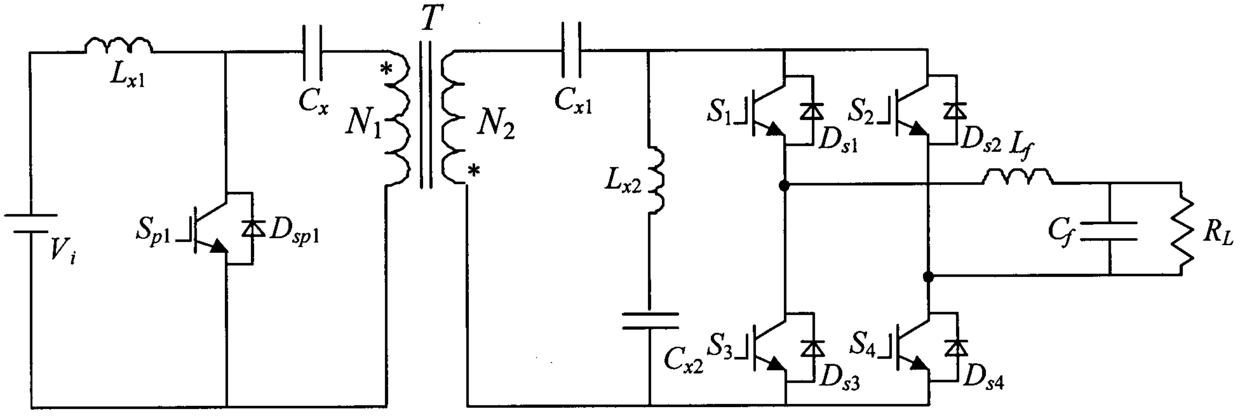

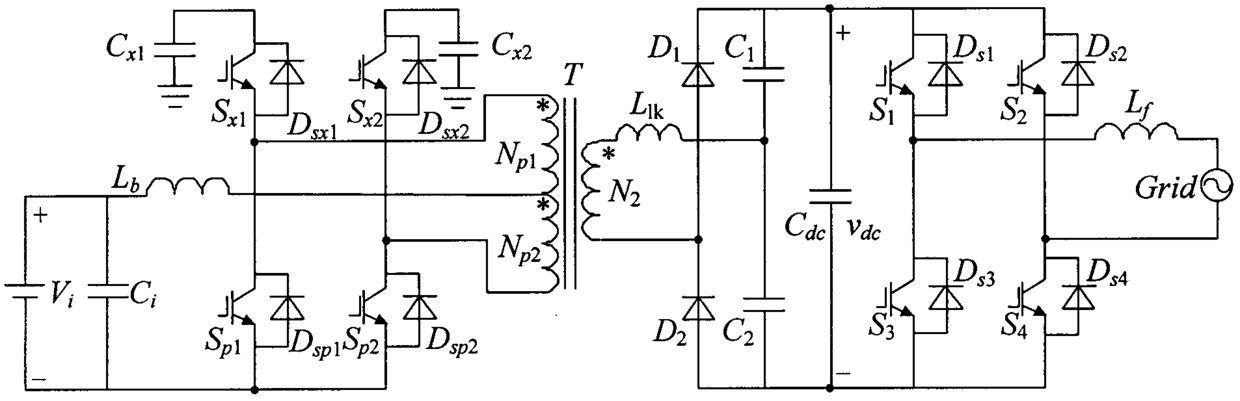

[0035] attached image 3 It is a structural schematic diagram of a main circuit of a non-isolated inverter for suppressing ripple and its control method. by the DC power supply V i , input capacitor 1, boost inductor 2, main switch tube 3, freewheeling diode 4, intermediate DC bus capacitor 5, two inverter bridge arms 6 and 7, filter circuit 8, auxiliary inductor 9, auxiliary switch tube 10, auxiliary Composed of diode 11 and auxiliary capacitor 12. C i is the input capacitance, L b is the boost inductor, L x1 , L x2 is the auxiliary inductance, D x1 、D x2 is the auxiliary diode, S x1 , S x2 is the auxiliary switch tube, S b is the main switching tube, D b is the freewheeling diode, C x is the auxiliary capacitor, C dc is the intermediate DC bus capacitance, S 1 ~S 4 is the power switch tube, L f is the output filter inductor, C f is the output f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com