Assembly method of an embedded part, electronic equipment shell and electronic equipment

A technology of electronic equipment and assembly method, which is applied in the direction of cabinet/cabinet/drawer parts, etc., can solve the problem of mismatch between product shell and external product shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

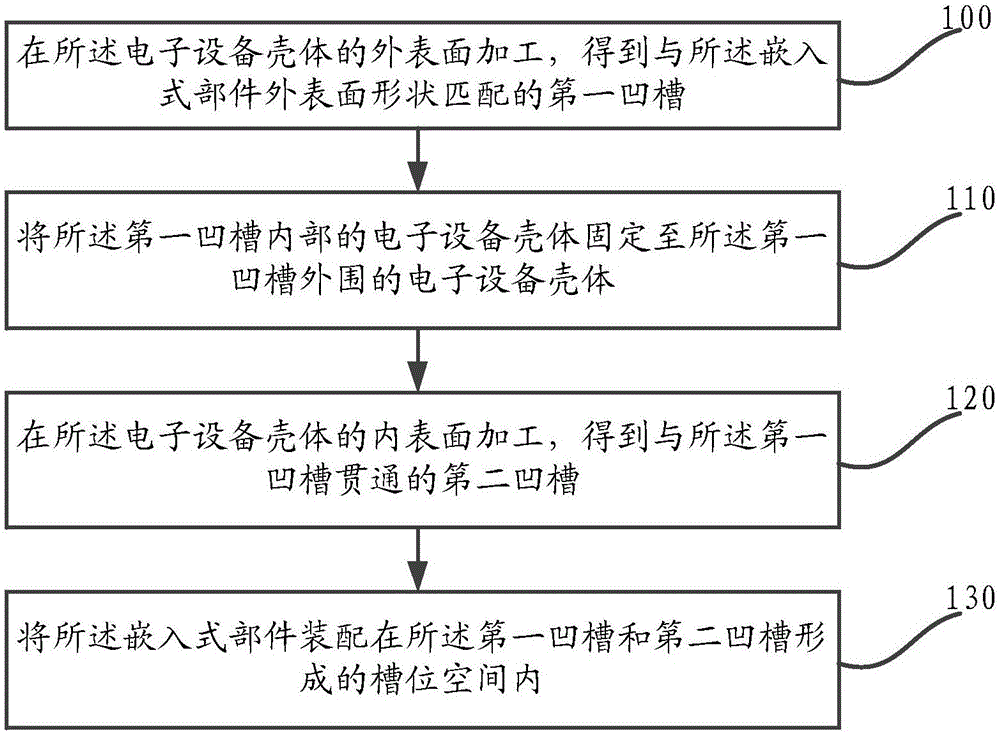

[0022] This embodiment provides a method for assembling embedded components, such as figure 1 As shown, the method includes steps 100 to 130 .

[0023] Step 100: Process the outer surface of the electronic device housing to obtain a first groove that matches the shape of the outer surface of the embedded component.

[0024] A groove matching the shape of the embedded part is milled out on the outer surface of the electronic device casing at a preset position for assembling the embedded part, which is used as a first groove for accommodating the part. the embedded components. The electronic device housing inside the first groove is the electronic device housing inside the embedded component after the assembly is completed; the electronic device housing outside the first groove is the electronic device housing surrounding the embedded component after the assembly is completed body. Taking the embedded component as an O-shape as an example, the shape of the first groove obtain...

Embodiment 2

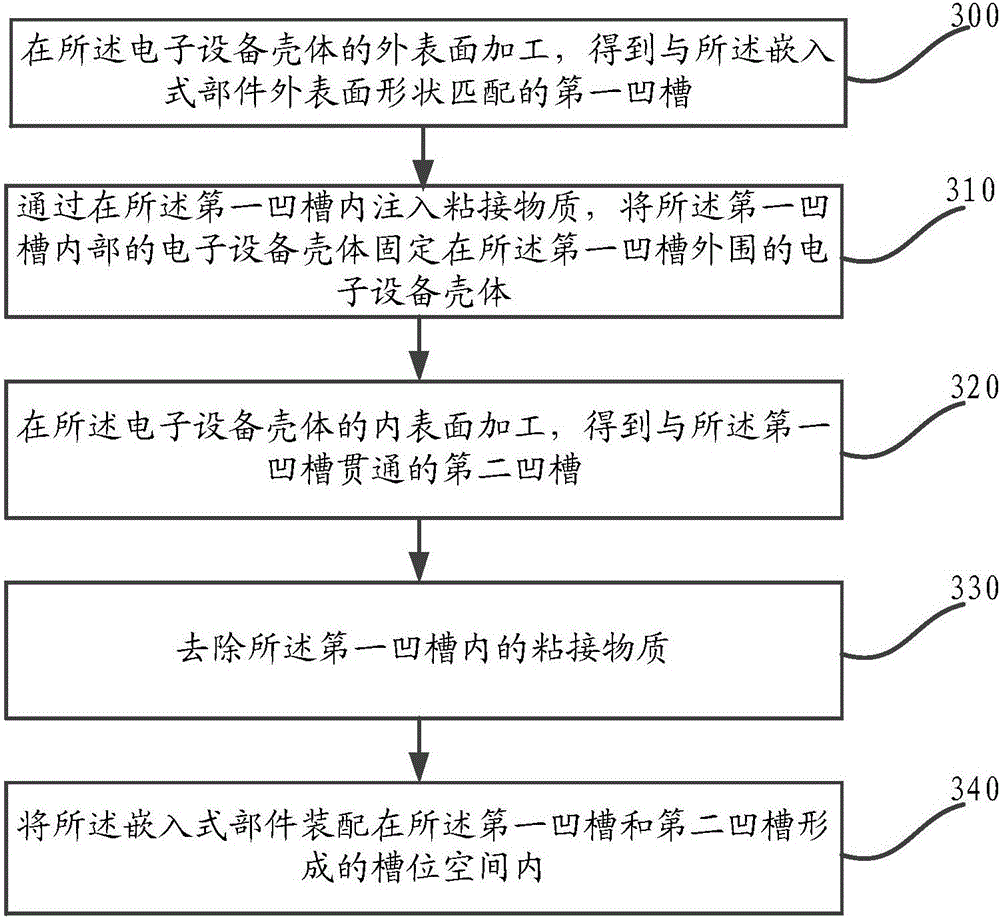

[0037] see image 3 , this embodiment provides a method for assembling an embedded component, the method includes steps 300 to 340 .

[0038] Step 300: Process the outer surface of the electronic device housing to obtain a first groove that matches the shape of the outer surface of the embedded component.

[0039] The specific implementation of processing the first groove matching the shape of the outer surface of the embedded component on the outer surface of the electronic device housing can refer to Embodiment 1, and details are not repeated here.

[0040] Step 310 , by injecting an adhesive substance into the first groove, the electronic device casing inside the first groove is fixed to the electronic device casing outside the first groove.

[0041] In this embodiment, the electronic device casing inside the first groove and the electronic device casing outside the first groove are fixed by injecting an adhesive substance into the first groove as an example, A specific s...

Embodiment 3

[0055] refer to Figure 5 , correspondingly, the embodiment of the present invention also discloses an electronic device casing 50 . The electronic device housing 50 includes: an embedded component 501 , and the embedded component 501 is assembled on the electronic device housing 50 according to the embedded component assembling methods disclosed in the first and second embodiments.

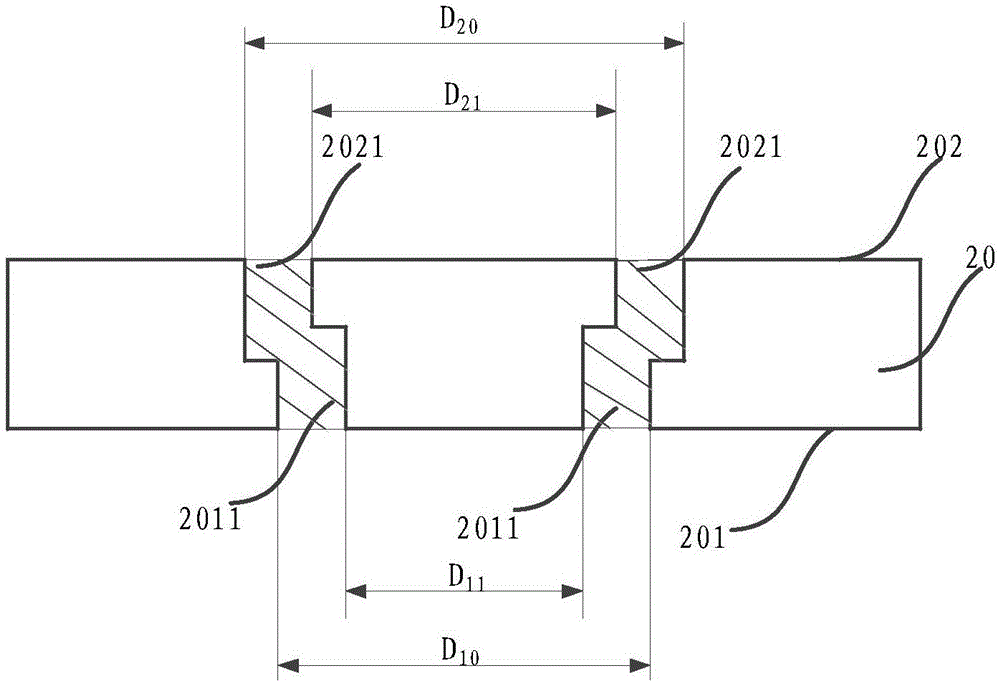

[0056] During specific implementation, firstly, a first groove matching the shape of the outer surface of the embedded component is processed on the outer surface of the electronic device casing; The outer surface covering sticker of the equipment casing fixes the electronic equipment casing inside the first groove to the electronic equipment casing outside the first groove; then, the inner surface of the electronic equipment casing is processed a second groove that communicates with the first groove; finally, the embedded component is assembled in the slot space formed by the first groove and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com