Epitaxial wafer used for schottky diode and preparation method for epitaxial wafer

A technology of Schottky diodes and epitaxial wafers, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high leakage current, low crystal quality, and high dislocation density of diode electronic devices, and achieve improved feedback To the breakdown voltage and forward conduction current, increase the barrier height, and reduce the effect of dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

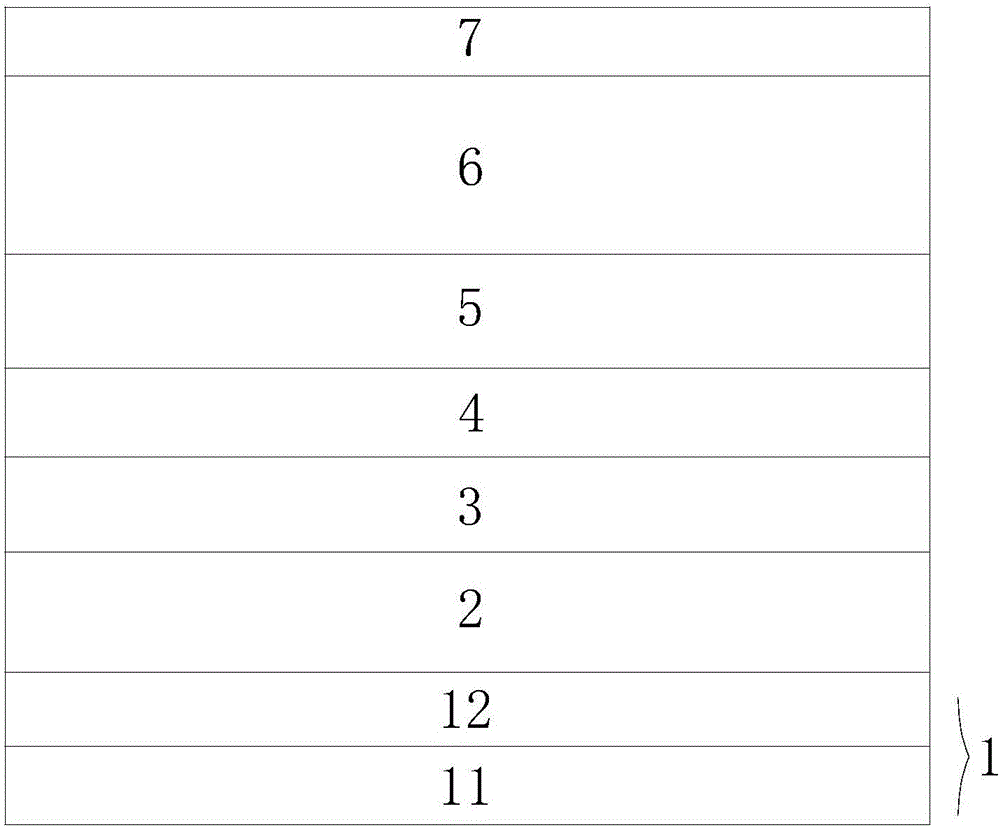

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] see figure 1 As shown, an epitaxial wafer for a Schottky diode, including a substrate and a GaN two-dimensional growth layer, a SiNx template layer, a GaN recovery layer, a heavily doped nGaN layer, Lightly doped nGaN layer, InAlN cap layer.

[0028] Wherein, the substrate is a sapphire flat plate 11 substrate with an AlN capping layer 12, which is made on the sapphire flat plate 11 by the AlN capping layer 12 using PVD or sputter equipment, and the thickness of the AlN capping layer 12 is 5~200nm.

[0029] The SiNx template layer is a GaN two-dimensional growth layer using SiH 4 and NH 3 Formed by in-situ growth, the thickness of the SiNx layer is less than one atomic layer.

[0030] Here, by replacing the low-temperature GaN layer with the AlN capping layer 12 and cooperating with the SiNx template layer, the edge dislocation den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com