Cylinder head for a compressor with particularly efficient air cooling

A compressor and air technology, applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problems of pressure loss and structural costs, and achieve the effects of small wall thickness, efficient cooling, and reduced surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

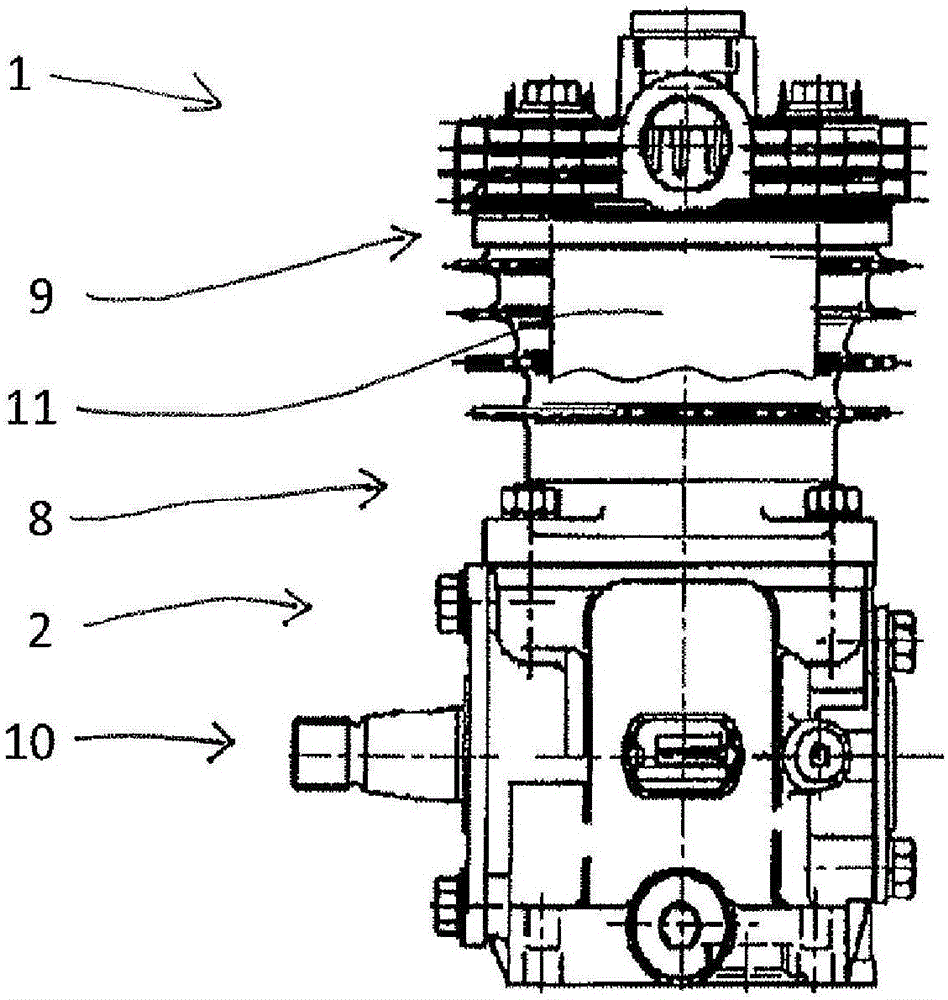

[0025] according to figure 1 , the compressor 2 has a cylinder head 1 and a piston housing 8 , wherein a valve plate 9 is arranged between the piston housing 8 and the cylinder head 1 . The compressor 2 is driven via a shaft 10 . The piston housing 8 is sectioned near the valve plate 9 so that the piston chamber 11 is visible. A piston, not shown here, moves axially up and down inside the piston chamber 11 .

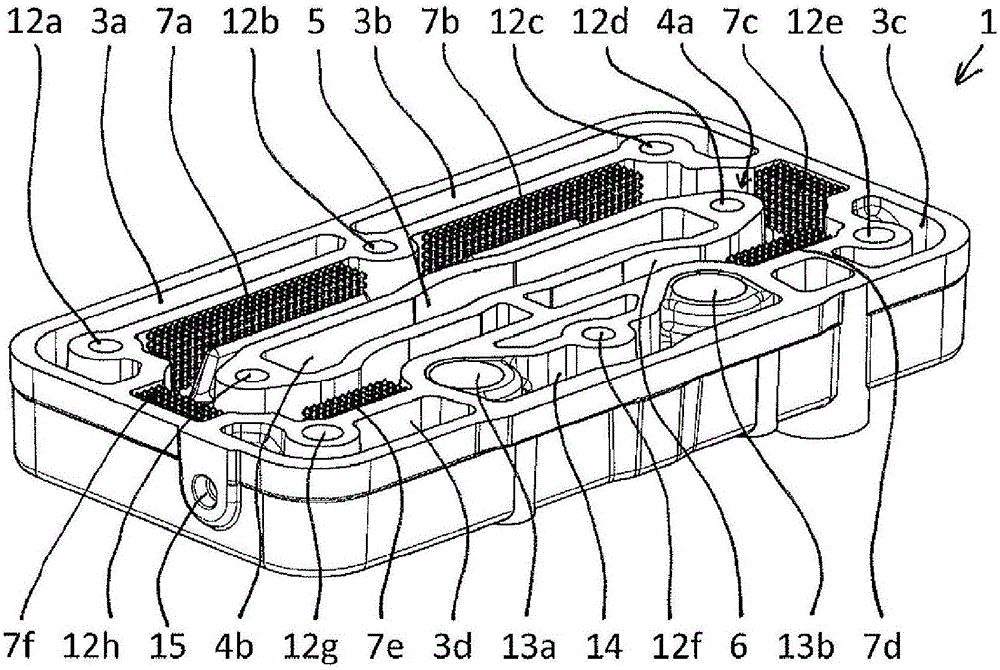

[0026] according to figure 2 , the cylinder head 1 has four coolant guide areas 3a-3d and two air guide areas 4a, 4b. Four coolant guide areas 3a-3d are arranged substantially around the two air guide areas 4a, 4b, wherein the four coolant guide areas 3a-3d directly adjoin the air guide area 4a in order to cool the compressed air. The valve plate 9 is also meandered through by coolant guide channels, not shown here.

[0027] The two air conduction areas 4 a , 4 b comprise an air inlet channel 5 for feeding air to be compressed into the compressor 2 and an air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com