Anti-backdrive actuator assembly

A reverse drive, actuator technology, applied in transmissions, gear drives, belts/chains/gears, etc., to solve problems such as increasing system cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

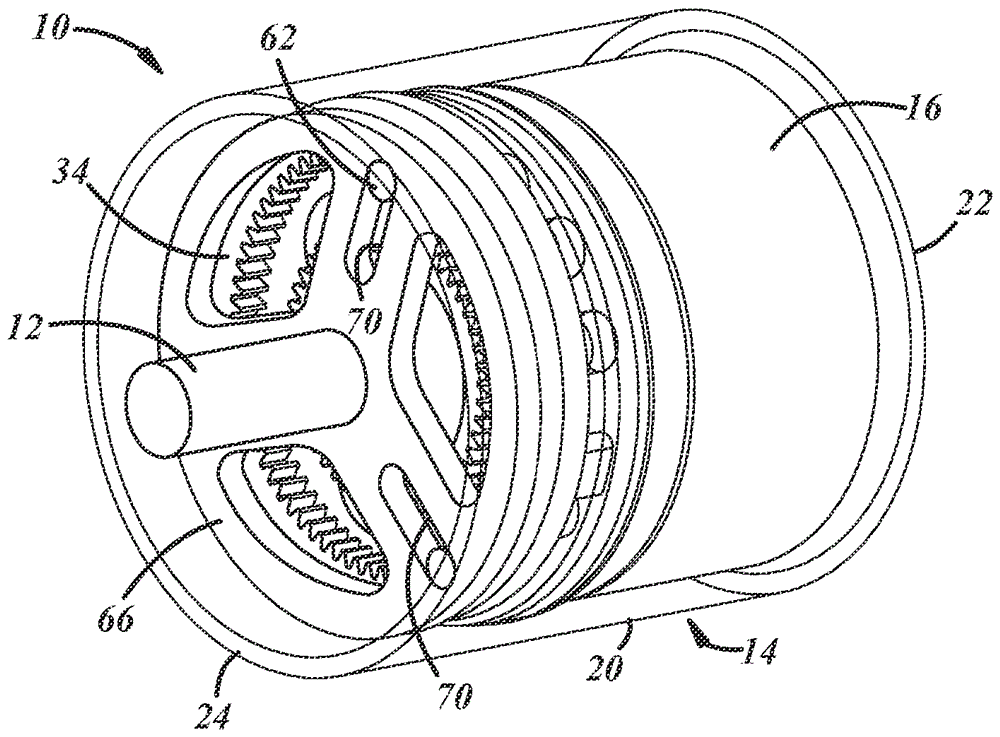

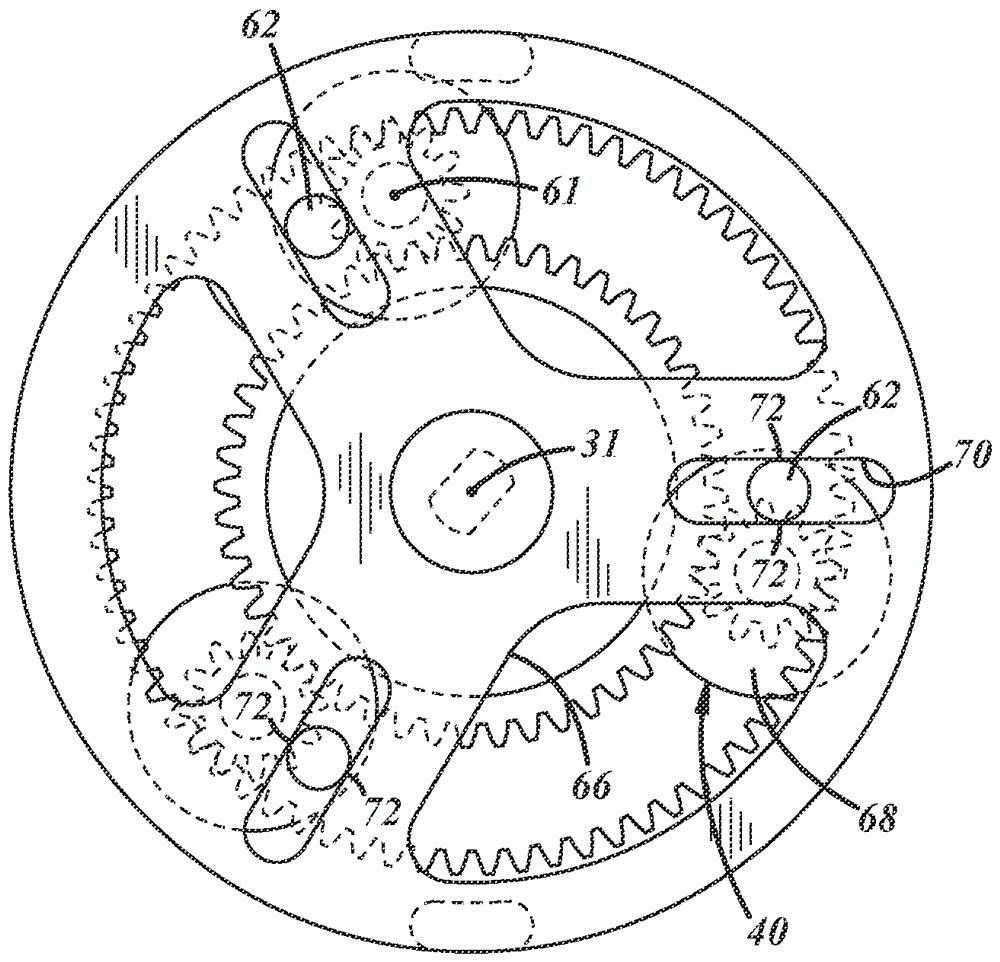

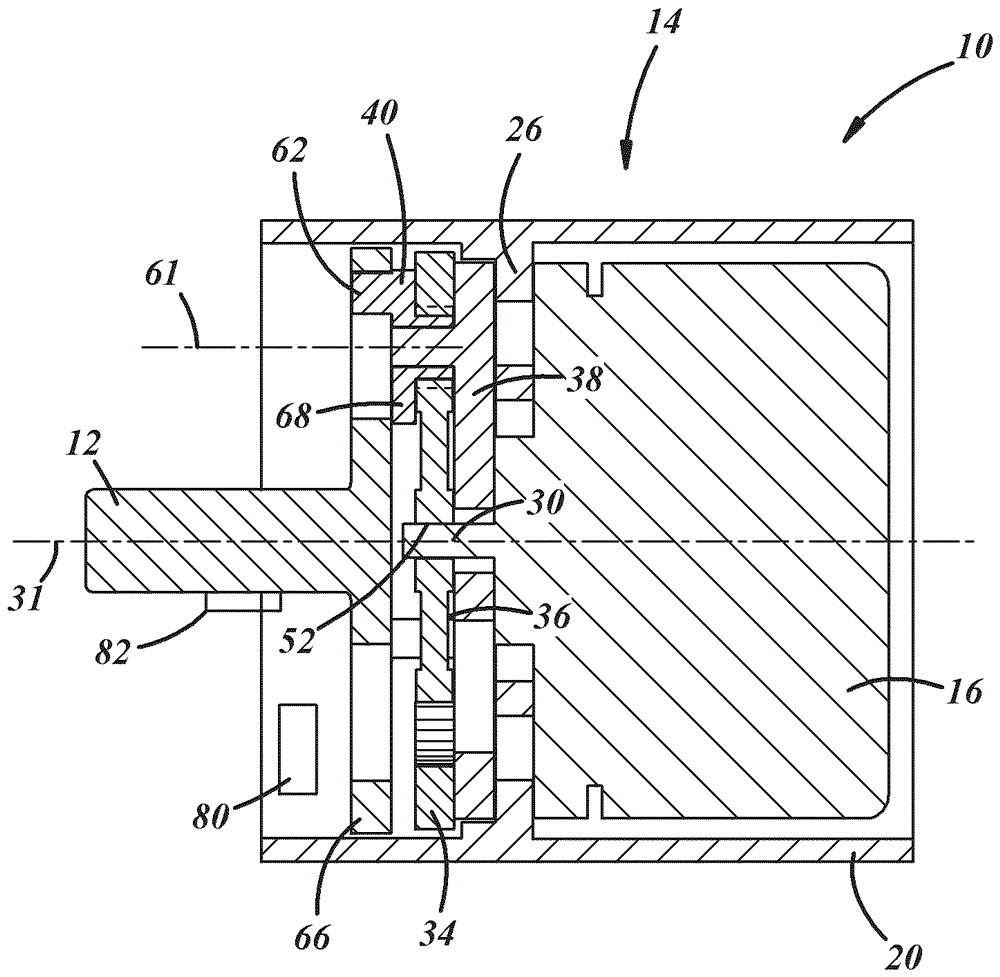

[0013] Referring to the accompanying drawings in more detail, Figure 1-3 An actuator assembly 10 is shown having an output, which may be or include an output shaft 12, which is rotated to move the device and to selectively prevent the device from back-driving the actuator assembly. The term "back-driven" is intended to mean that the device rotates the actuator assembly, in other words, the output drives the input and not the other way around. The means driven by the actuator assembly 10 may include cams, gears, or the like, and the motion may be continuous in the forward direction, in forward and reverse directions, or back and forth between two or more positions, as desired in discrete segments of motion. The actuator assembly 10 can be used with many different devices, one example of which is a gear selector for an automotive transmission, wherein rotation of the assembly causes rotation of the gear selector, thereby changing the selected and engaged transmission gear (fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com