Portable refillable cream dispenser

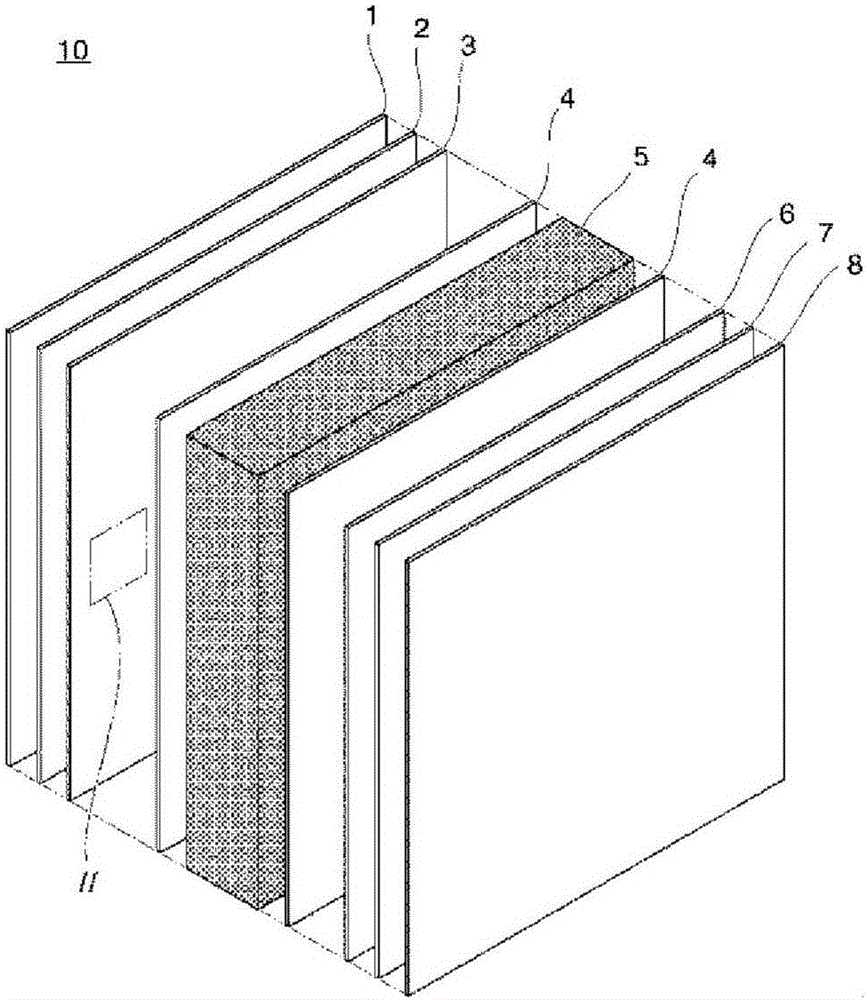

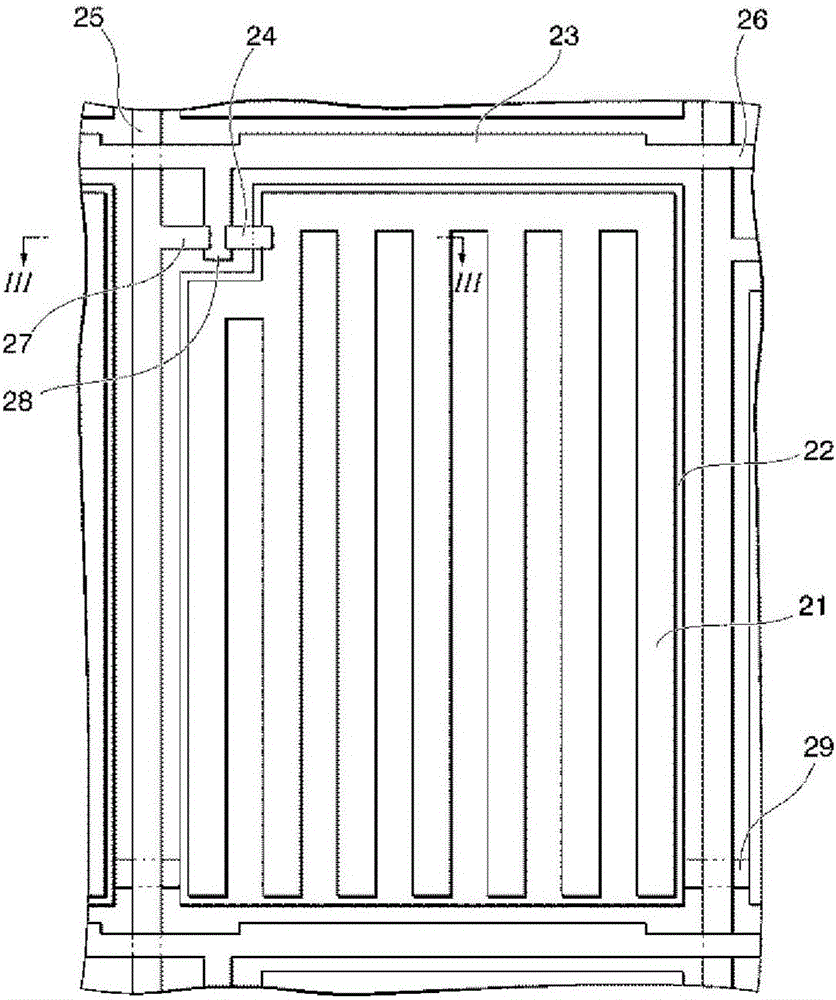

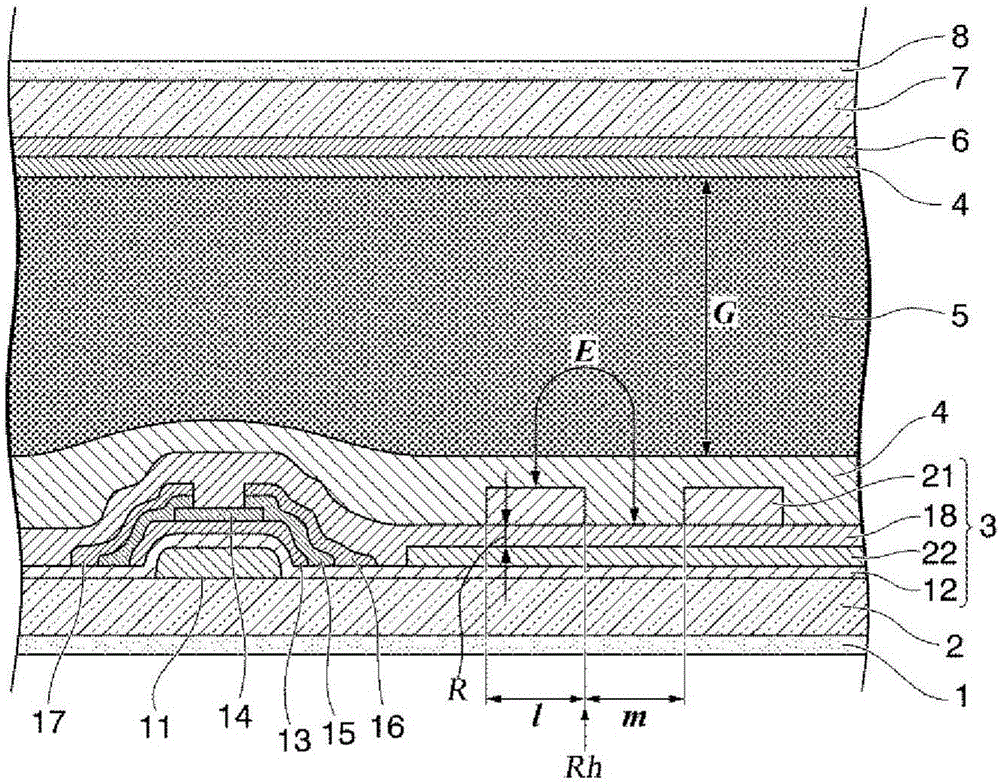

一种液晶显示元件、液晶层的技术,应用在液晶材料、光学、仪器等方向,能够解决显示元件影响大等问题,达到显示不良少、优异显示特性、高速响应性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0258] (Example 1 (Liquid Crystal Composition 1) and Comparative Example 1)

[0259] A liquid crystal composition (liquid crystal composition 1) having the composition shown below was prepared, and its physical property values were measured. The results are shown in the table below.

[0260] Furthermore, the prepared liquid crystal composition 1 was poured into the said liquid crystal display element, and the evaluation of various physical property values and display characteristics was performed.

[0261] Simultaneously, the liquid crystal composition of Comparative Example 1 having a different structure from the liquid crystal composition specified in the present invention was prepared, and a liquid crystal display element was fabricated and evaluated in the same manner.

[0262] In addition, the symbol on the left side of the content is the description of the abbreviation of the said compound.

[0263] [chem 30]

[0264] Example 1

[0265]

[0266] [chem 31]

Embodiment 2

[0273] (Example 2 (Liquid Crystal Composition 2) and Comparative Example 2)

[0274] A liquid crystal composition (liquid crystal composition 2) having the composition shown below and the liquid crystal composition of Comparative Example 1 were prepared, and an FFS mode liquid crystal display element was prepared in the same manner, and its physical properties were measured. The results are shown in the table below.

[0275] Simultaneously, the liquid crystal composition of Comparative Example 2 having a different structure from the liquid crystal composition specified in the present invention was prepared, and a liquid crystal display element was fabricated and evaluated in the same manner.

[0276] [Table 2]

[0277] Sample name Example 2 Comparative example 2 T NI / ℃

86.5 89.7 Δn 0.110 0.088 Δε -3.90 -3.32 n / mPa·s 22.0 21.0 gamma 1 / mPa·s

144 162 gamma 1 / Δn 2

11.9 20.9 gamma 1 / Δn 2 / |Δε|

3.05 ...

Embodiment 3 to 8

[0281] The liquid crystal compositions of Examples 3 to 8 having the compositions shown below were prepared, and an FFS mode display element was produced in the same manner, and its physical property values were measured. The results are shown in the table below.

[0282] [table 3]

[0283] Sample name Example 3 Example 4 Example 5 Example 6 Example 7 Example 8 T NI / ℃

[0284] It can be seen that the liquid crystal display elements of Examples 3 to 8 also have characteristics practical as liquid crystal TVs, and flicker characteristic to the FFS mode is effectively reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com