A paper shredder control circuit

A control circuit and trigger control circuit technology, applied in grain processing, etc., can solve the problems that restrict the popularization of paper shredders, limited functions, and unclean shredding of paper tails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

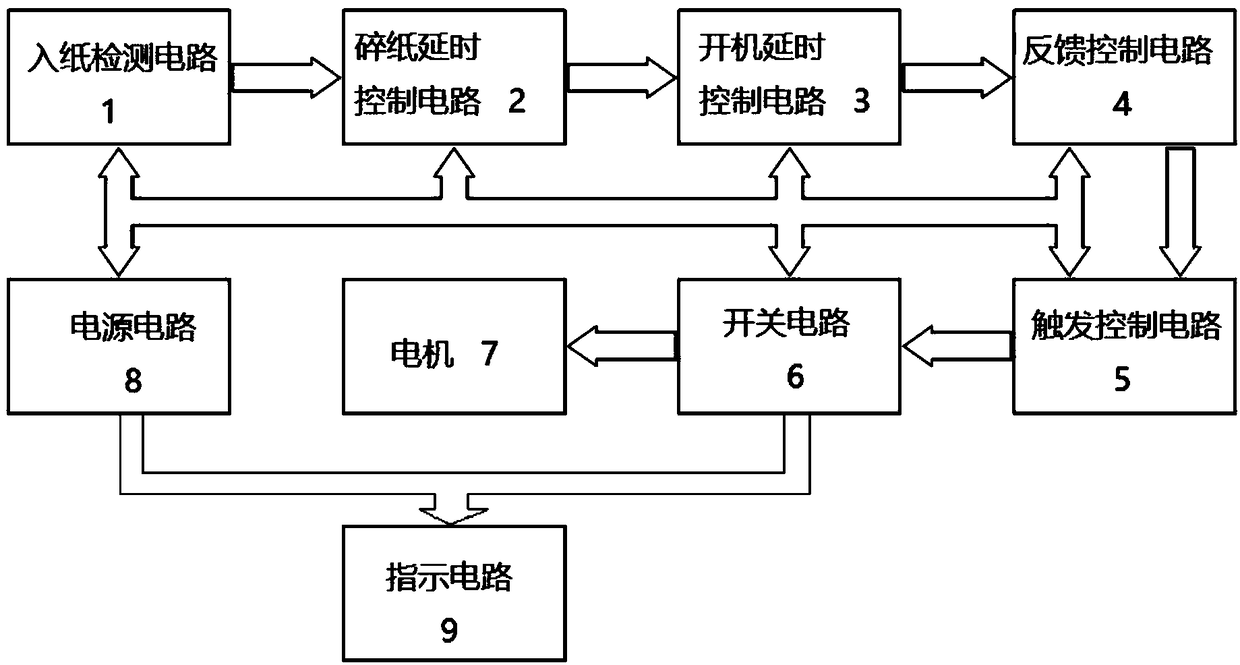

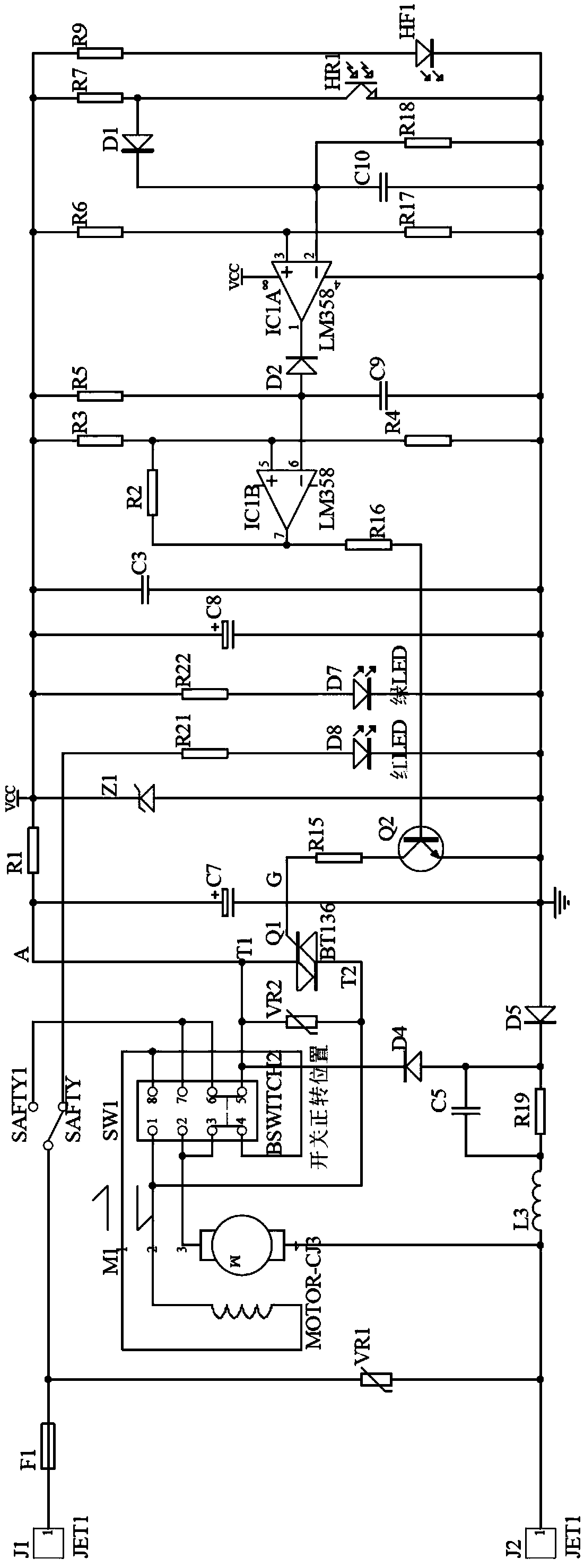

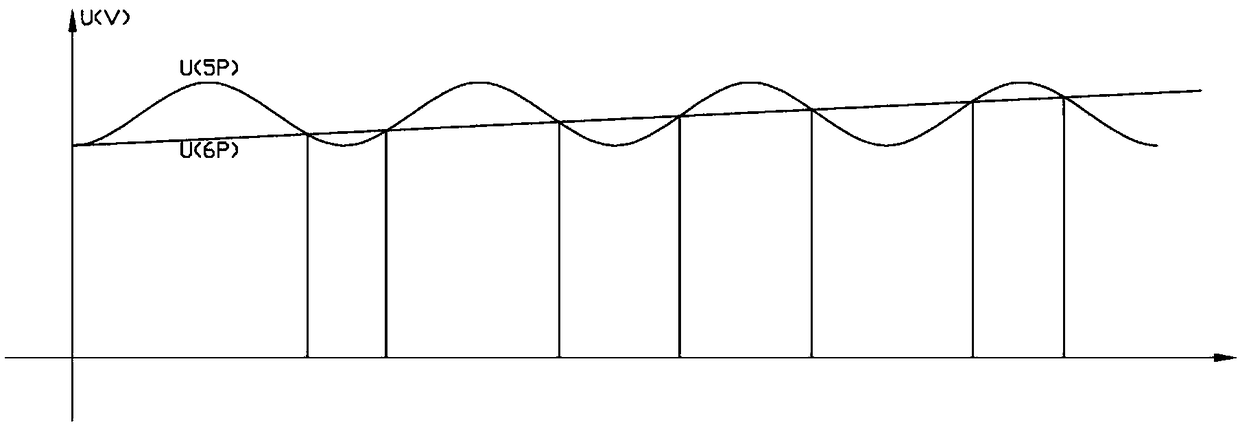

[0040] See figure 1, a paper shredder control circuit in this embodiment includes a paper entry detection circuit 1, a paper shredding delay control circuit 2, a power-on delay control circuit 3, a feedback control circuit 4, a trigger control circuit 5, a switch circuit 6, a motor 7. Power supply circuit 8 and indicator circuit 9; paper entry detection circuit 1, used to control whether to start the switch circuit 6 according to detecting whether there is paper put into the shredder opening of the shredder; paper shredding delay control circuit 2 and power-on The delay control circuit 3 is used to control the shutdown delay time and the startup delay time by changing the resistance value and capacitance of the capacitor; the feedback control circuit 4 is used to provide positive feedback to the startup delay control circuit 3, so that the broken When the paper machine starts or stops, the reference voltage of the circuit rises or pulls down; the trigger control circuit 5 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com