Window film clipping equipment

A technology of equipment and window film, applied in the field of window film cutting equipment, can solve the problems of high efficiency, low efficiency, uneven cutting, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

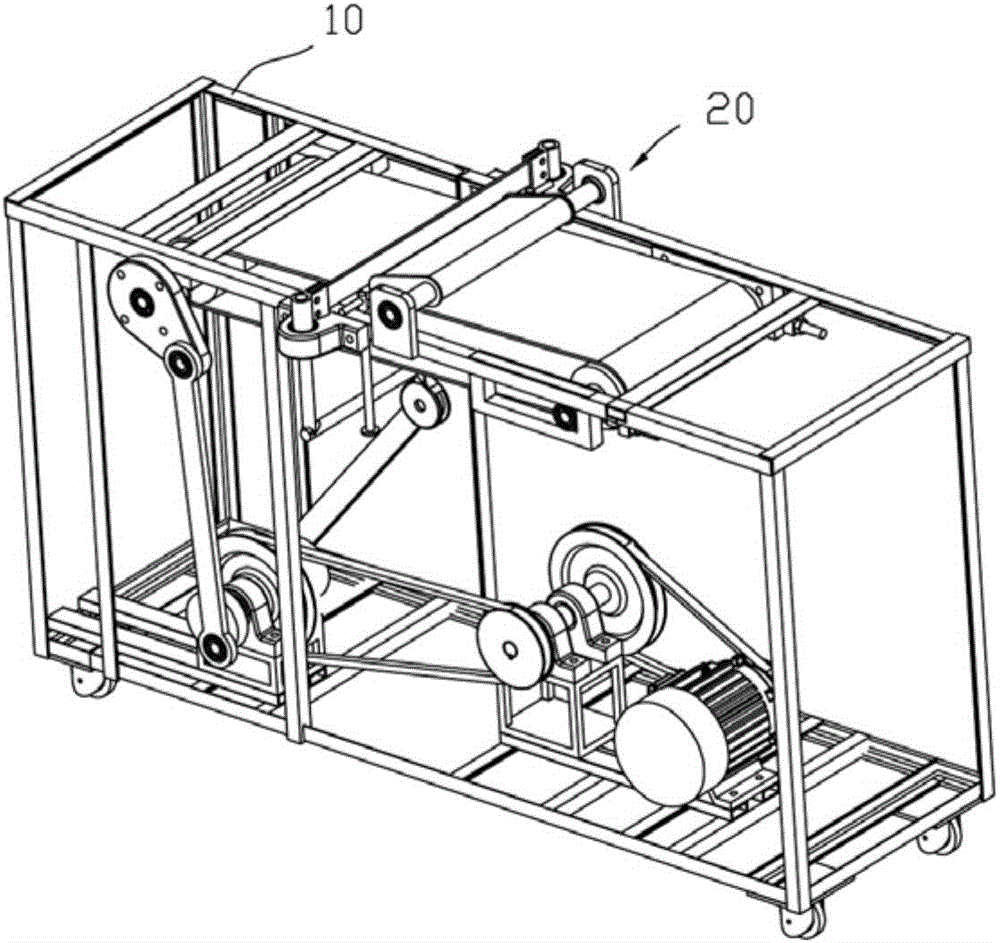

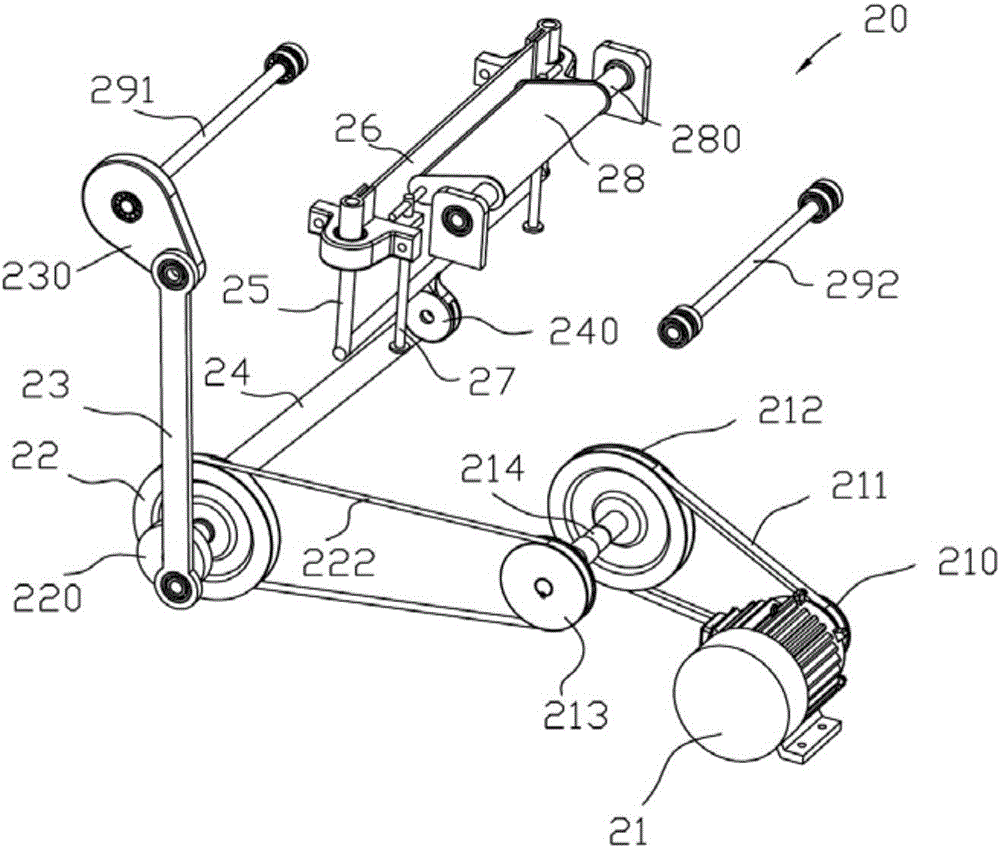

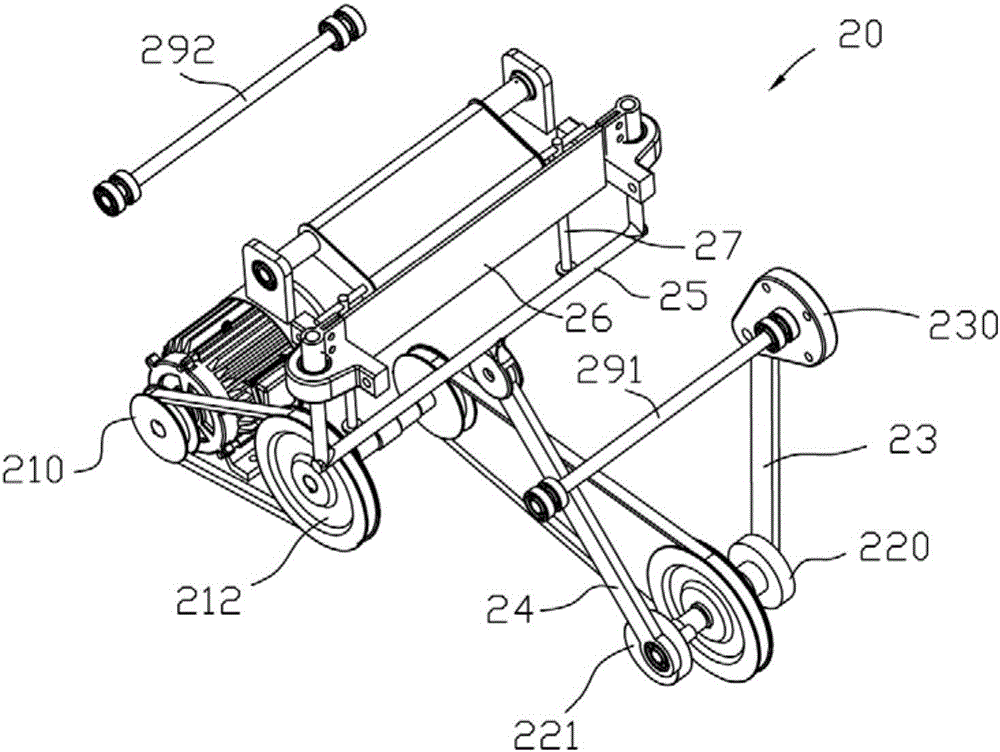

[0022] Such as Figure 1 to Figure 3 As shown, a window film cutting equipment includes a bracket 10, a rotating assembly 20 is arranged in the bracket 10, and the rotating assembly 20 includes a motor 21, and the output end of the motor 21 is provided with a first pulley 210. The first pulley 210 is connected with the second pulley 212 through the first belt 211, the second pulley 212 and the third pulley 213 are installed on the connecting shaft 214, and the third pulley 213 and the fourth pulley 22 are connected through the first pulley 213. Two belts 222 are connected, and the side of the fourth pulley 22 is provided with a second eccentric wheel 221, and the second eccentric wheel 221 is connected with the second rocker 24, and the second rocker 24 is connected to the second rocker 24 through the pivot block 240. The cutter frame 25 is connected, and the cutter body 26 is installed on the cutter frame 25 .

[0023] Such as figure 2 with image 3 As shown, the other si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap