Payment device cycle print test structure and test method

A technology for payment equipment and testing structures, applied in printing devices, printing, etc., can solve the problems of large printing paper consumption, waste of manpower and material resources, and low efficiency, and achieve the effect of not wasting paper, improving efficiency, and liberating human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

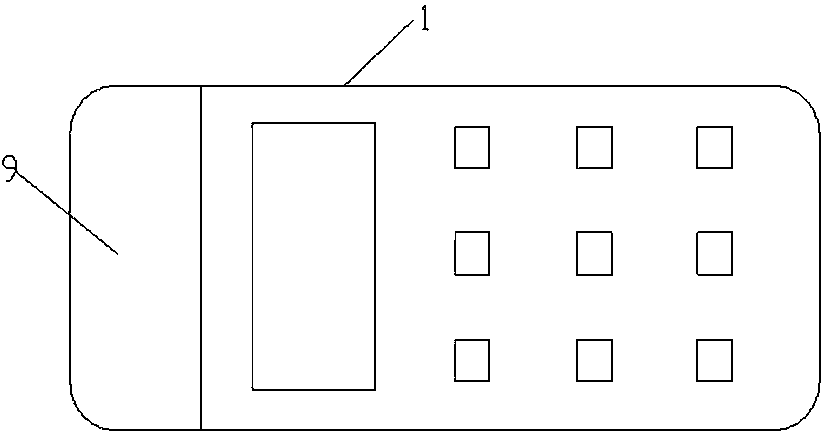

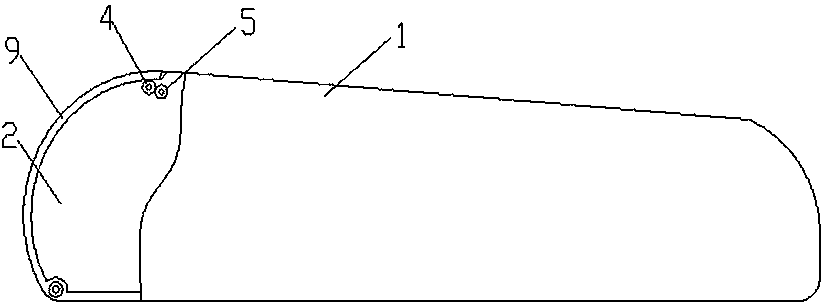

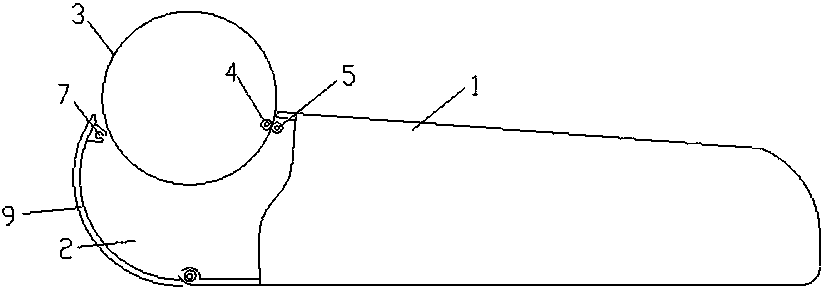

[0020] The circulation printing test structure of the payment device of the present invention includes a body 1 and a paper slot 2 arranged in the body 1 for holding printing paper, and a printing head and a detachable printer located at the side of the printing head are arranged on the side of the paper slot 2. The reel 4 and the fixed reel 5, the detachable print reel 4 and the fixed reel 5 rotate against each other, the end of the detachable print reel is provided with a first meshing gear 6, and the body 1 is provided with a first meshing gear Mesh and rotate the second meshing gear 8, the second meshing gear 8 can be driven by a motor to rotate, or driven by other intermediate gears, the detachable printing reel is installed on the openable cover 9, the machine One side of the cover 9 is hinged on the body, and the body 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com