Dry-hanging fastener for interior and exterior wall decoration material of building and dry-hanging installation structure

It is a technology for exterior wall decoration and building interior, which is applied in the direction of building structure, construction, covering/lining, etc. It can solve the problems that the quality of the card slot is difficult to control, and the strength of the interior and exterior wall decoration materials of the building is easily damaged, so as to improve the effect of sound insulation and heat preservation. The structure is firm and reliable, and the installation efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

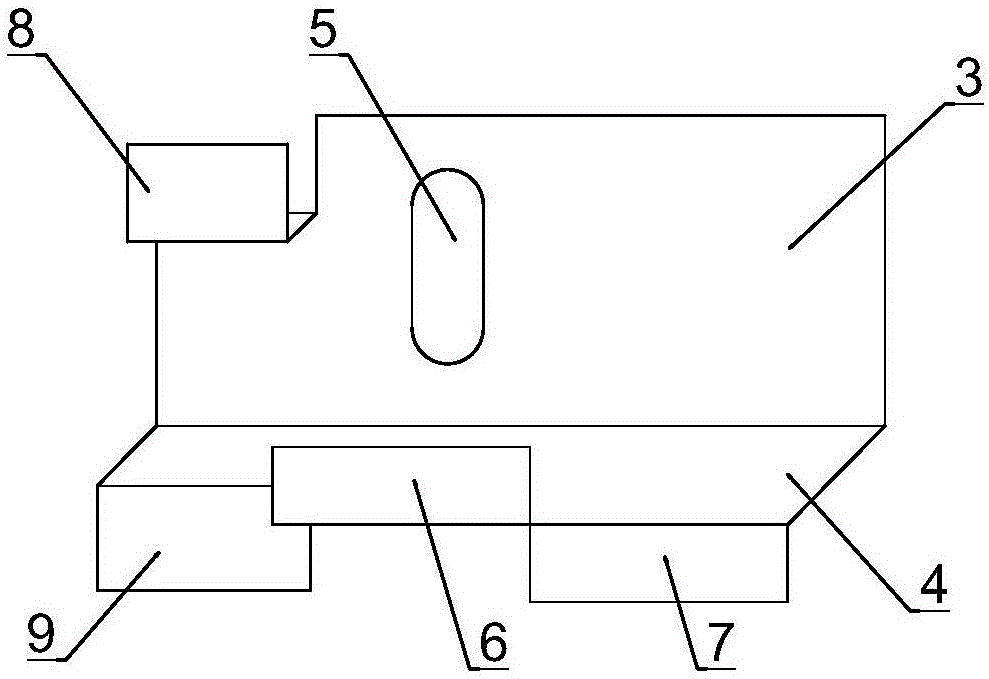

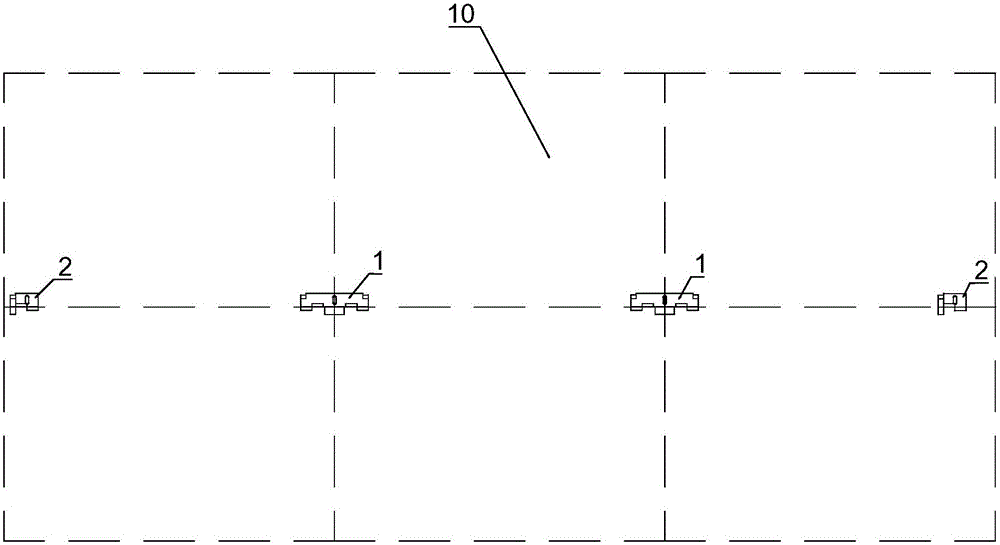

[0022] Such as figure 1 As shown, a dry-hanging fastener for interior and exterior wall decoration materials of a building, the end face of the dry-hanging fastener is L-shaped, includes a backboard 3 and a horizontal board 4 that are perpendicular to each other, and has a mounting hole 5 on the backboard 3. The hanging fastener is a short type dry hanging fastener 2, and only a pair of buckles are arranged on the outer edge of the horizontal plate 4;

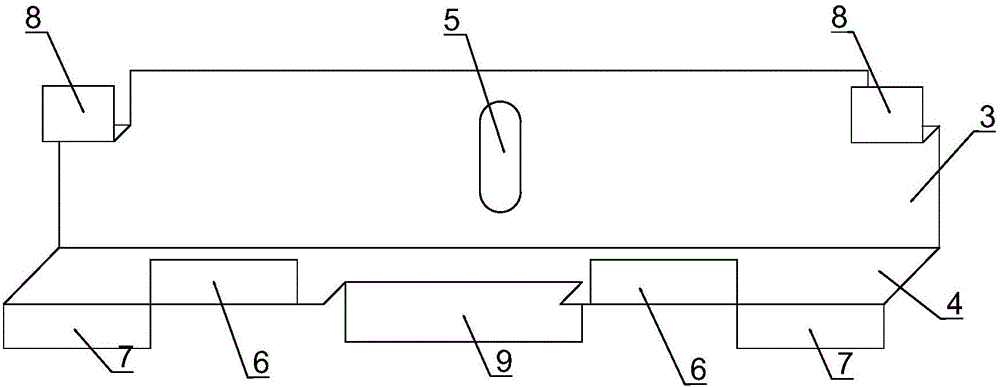

[0023] or, as in figure 2 As shown, the dry-hanging fastener is a long-type dry-hanging fastener 1, a pair of buckles are respectively arranged on the left and right sides of the outer edge of the horizontal plate 4, and the two pairs of buckles are arranged at intervals, and each pair of buckles includes an upward upper The buckle 6 and a lower buckle 7 facing downwards, the upper buckle 6 and the lower buckle 7 of each pair of buckles are arranged adjacent to each other.

[0024] On the dry hanging fastener, there are also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com