Ventilative and lighting silencing window

A technology of sound-absorbing and sound-absorbing panels, which is applied in the direction of ventilation arrangement, sound-proof doors/windows, windows/doors, etc. It can solve problems affecting the health of personnel and working environment, easy fatigue, and the impact of personnel work, so as to increase the effect of absorbing and silencing, Beautiful design and the effect of solving noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

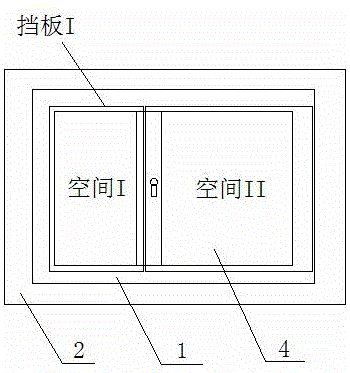

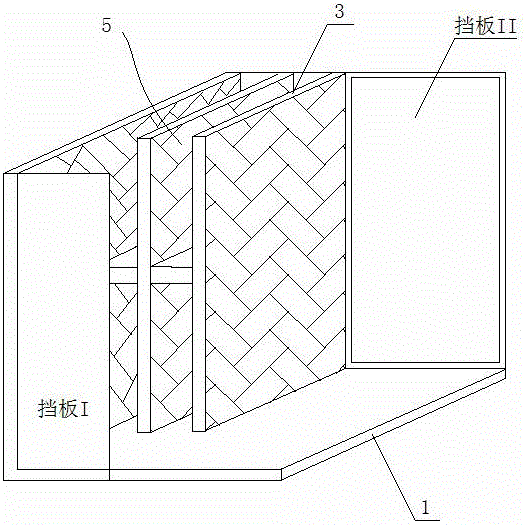

[0017] Such as figure 1 , 2 As shown, a kind of ventilation and lighting sound-absorbing window includes a sound-absorbing frame 1, and a sound-absorbing frame 2 installed on one end edge of the sound-absorbing frame 1; , the inside of the sound-absorbing frame 1 is a through hole, one end of the opening faces indoors, and the other end faces outdoors. A sound-absorbing baffle 3 installed from the outdoor end of the sound-absorbing frame to the indoor end is arranged in the through-hole of the sound-absorbing frame 1, and the sound-absorbing baffle 3 There is a ventilation channel away from the indoor end, and the sound-absorbing baffle 3 divides the sound-absorbing frame 1 into two spaces I and II that connect the indoor and outdoor spaces. The baffle I is set at the opening of the space I facing the interior, and the space II faces the interior of the room. A window 4 is set at the opening, a baffle II is set at the opening of the space II facing the outside, and a sound-ab...

Embodiment 2

[0022] As a preferred design of Embodiment 1, the sound-absorbing grille 5 is composed of a vertical sound-absorbing plate parallel to the sound-absorbing baffle 3, a horizontal sound-absorbing plate arranged between the vertical sound-absorbing plate and the sound-absorbing baffle, and a vertical sound-absorbing plate arranged on the vertical sound-absorbing plate It is composed of a horizontal sound-absorbing plate between the sound-absorbing frame.

[0023] The sound-absorbing frame 2 is composed of a shell, a face shield grid plate and a sound-absorbing material filled in the middle; the sound-absorbing and insulating baffle 3, the vertical sound-absorbing plate, and the horizontal sound-absorbing plate are all composed of a frame shell and installed on the frame shell The armor grid panels on both sides of the body and the sound-absorbing material filled therein; one side of the two-side armor grid panels of the sound-absorbing and insulating baffle 3 is located in space I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com