Integrated multistage axial flow contrarotating turbine structure

A counter-rotating turbine, integrated technology, applied in the direction of non-variable engines, blade support components, engine components, etc., can solve the problems of multiple stages and large volume of turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

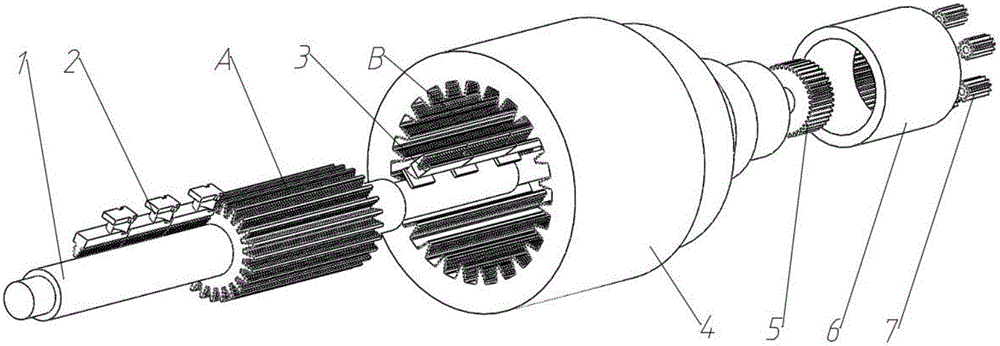

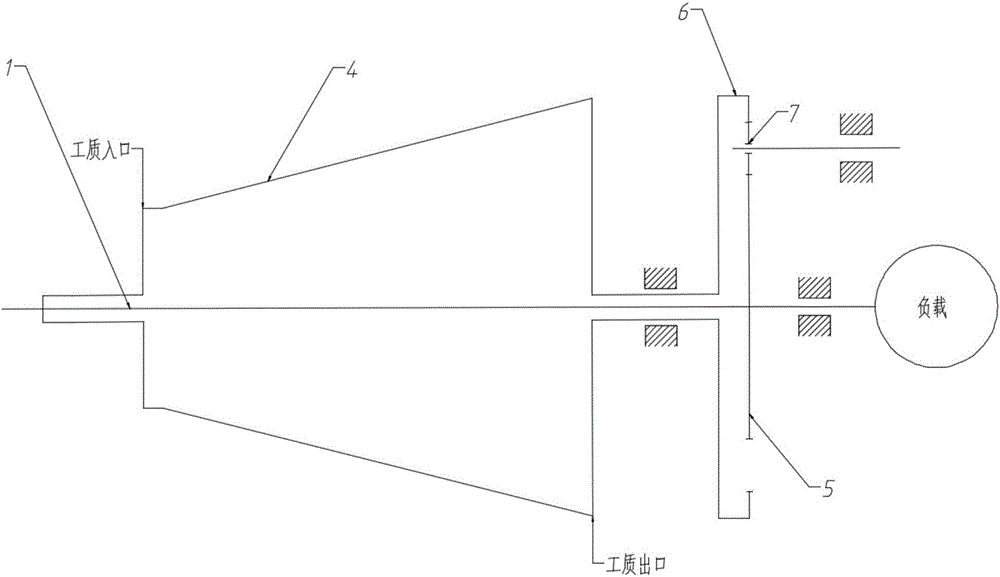

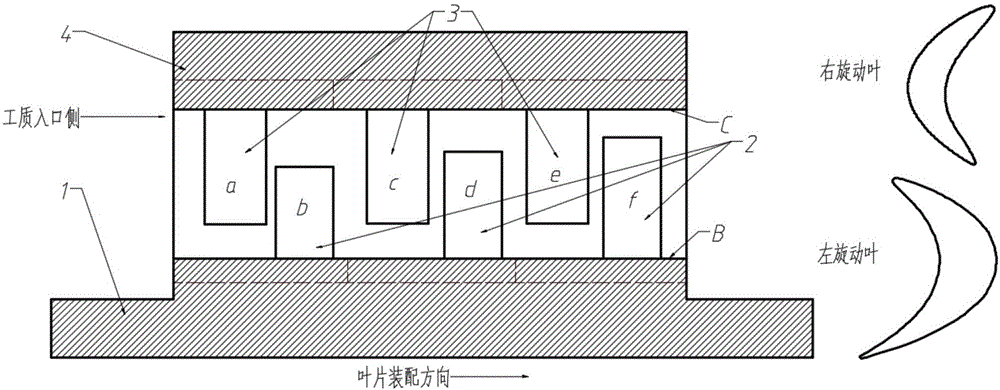

[0022] see figure 1 As described above, the present invention is a multi-stage integral axial-flow counter-rotating turbine structure, comprising: an inner rotor 1, an outer rotor 4, a sun gear 5, an outer ring gear 6 and a planetary carrier 7; the outer circumference of the inner rotor 1 is provided with several rows The left-handed blade slots A extending in the axial direction, the blade roots of several rows of left-handed blades are stuck in the corresponding left-handed blade slots A; the inner wall of the outer rotor 4 is provided with several rows of right-handed blade slots extending in the axial direction B, the blade roots of several rows of right-rotating blades are stuck in the corresponding right-rotating blade slots B.

[0023] The inner rotor 1, the left-handed rotor blades 2, the right-handed rotor blades 3 and the outer rotor 4 constitute t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com