A multi-stage radial flow counter-rotating turbine structure

A kind of contra-rotating turbine and radial flow technology, which is applied in the direction of non-variable-capacity engine, machine/engine, blade supporting element, etc., and can solve the problems of complex structure layout and large structure volume of multi-stage radial turbine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

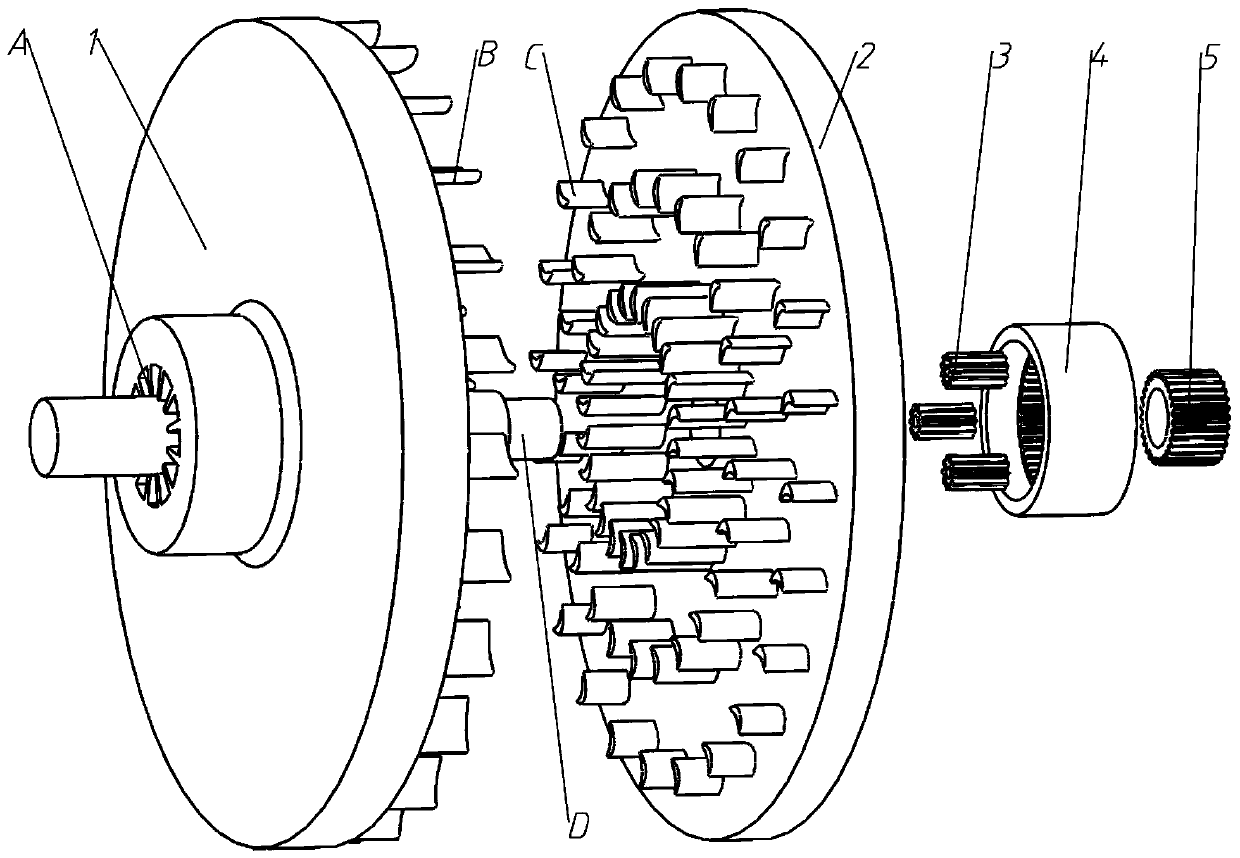

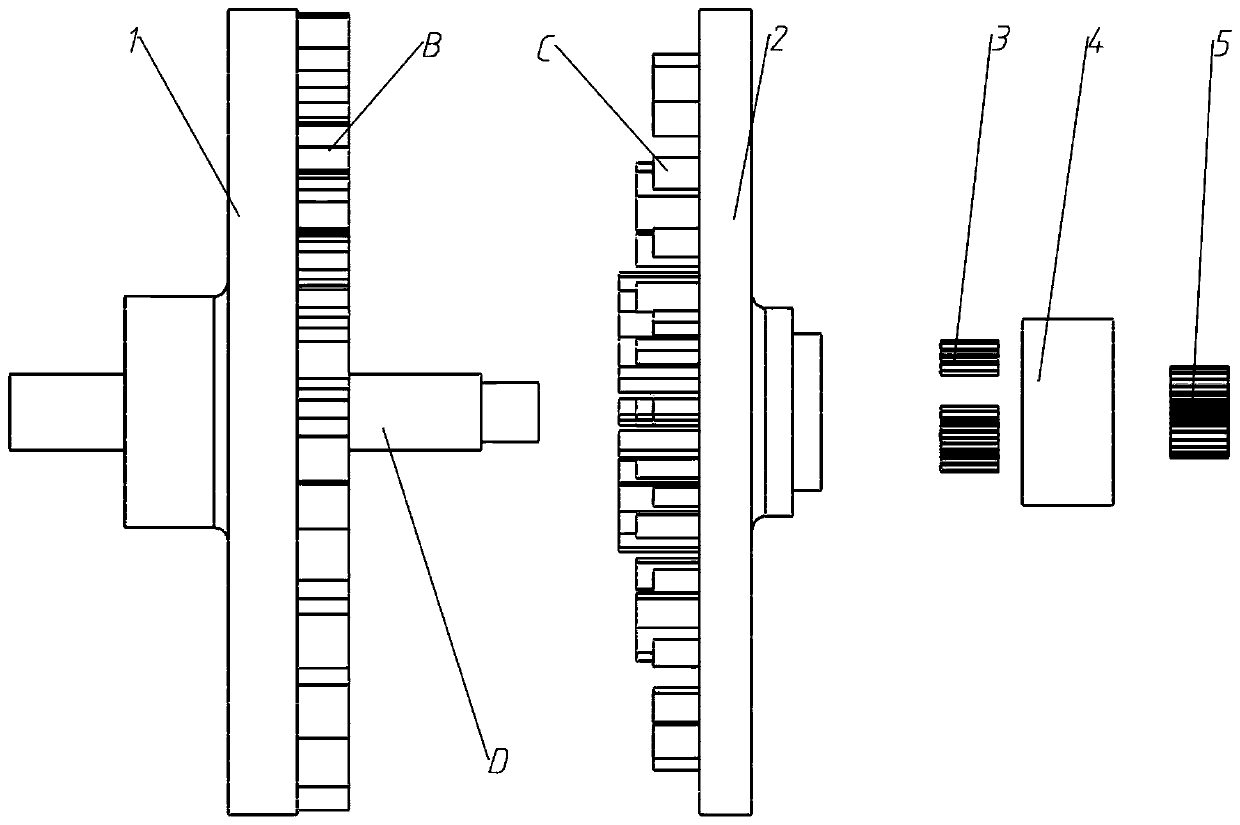

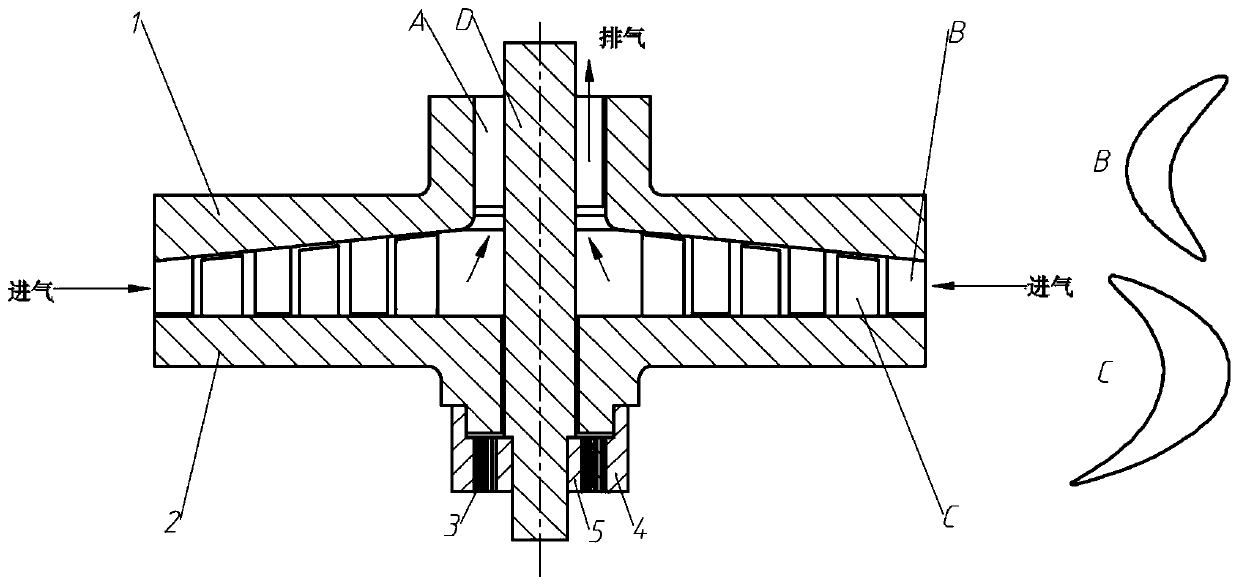

[0024] see Figure 1 to Figure 2 As mentioned above, the present invention is a multi-stage radial flow counter-rotating turbine structure, including: main impeller 1, auxiliary impeller 2, planetary carrier 3, outer ring gear 4 and sun gear 5; Radially arranged rotor blades B (main impeller blades), the axial center of the main impeller 1 is fixedly connected to the shaft D through the spoke belt A; the inside of the auxiliary impeller 2 is provided with several rows of radially arranged rotor blades C ( impeller blades).

[0025] The main impeller 1 and the auxiliary impeller 2 constitute the power generation system of the turbine, and the planet carrier 3, the outer ring gear 4 and the sun gear 5 constitute the power synthesis system of the turbine. The main impeller 1 and the sun gear 5 are coaxially arranged and fixedly connected; the auxiliary impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com