On-line checking method for turbo-generator set boiler inlet feed water flow

A technology of steam turbine generator set and feed water flow, which is applied in the direction of testing/calibrating volume flow, measuring flow/mass flow, liquid/fluid solid measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] An online verification method for boiler inlet feedwater flow of a turbogenerator unit, comprising the following steps:

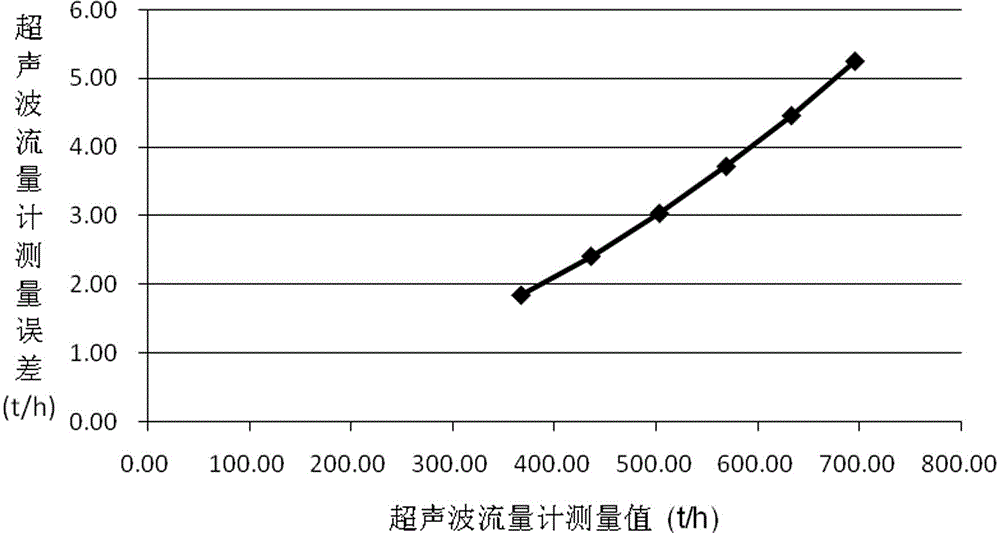

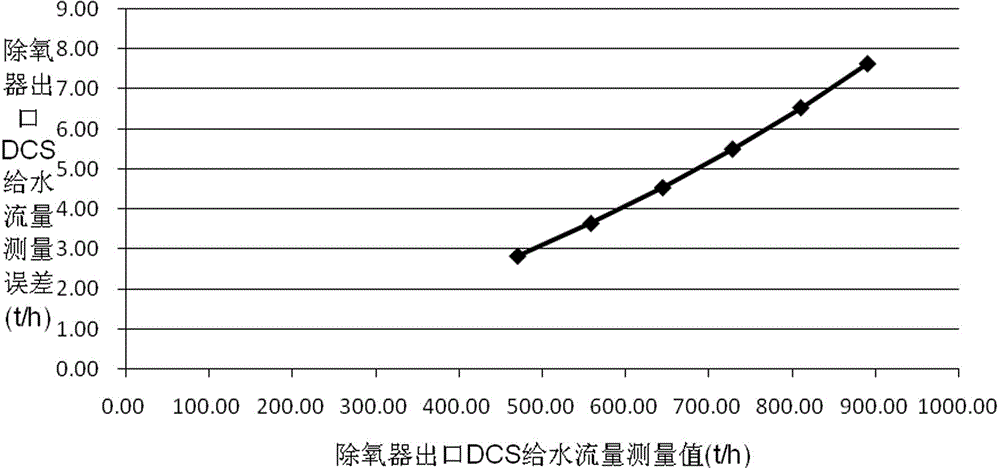

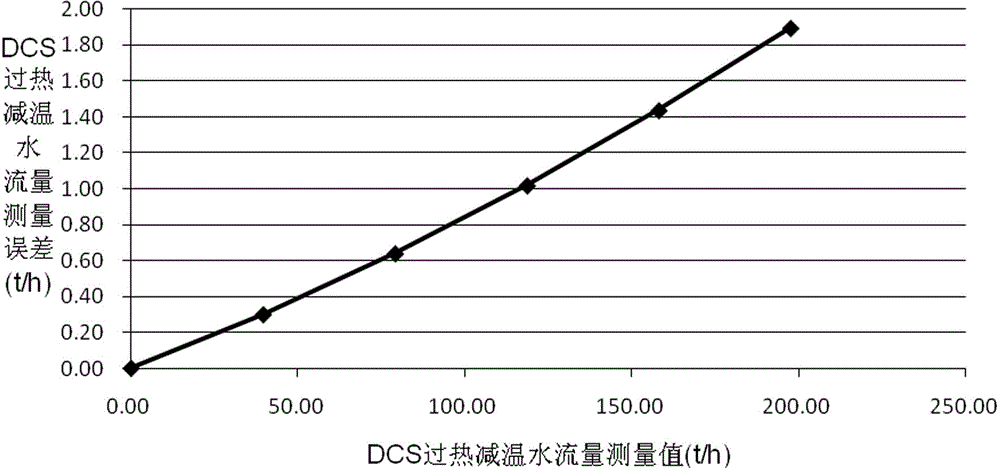

[0096] Step 1: On the A steam turbine generator set with ASME flow nozzle installed and rated capacity of 300MW, use the calibrated ASME flow nozzle to take the condensate flow at the inlet of the deaerator as the object, and carry out the measurement data of the high-temperature ultrasonic flowmeter Calibration; during calibration, the condensate flow change at the inlet of the deaerator covers the 50% to 100% load range of the turbogenerator unit operation, and every 10% load change is a calibration condition, a total of 6 calibration conditions, The average value of the data of each measurement working condition is shown in Table 1: set 6≥i≥1, under the i-th operating load, keep the condensate flow at the inlet of the deaerator stable, record the data at intervals of 20s, record the data for 20 minutes, Calculate the average value of the measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com