An online calibration method for boiler inlet feed water flow rate of steam turbine generator set

A steam turbine generator set, feed water flow technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, testing/calibrating volume flow, etc., to achieve stable and convenient measurement, high accuracy, and overcome poor accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0096] An online verification method for the inlet feedwater flow rate of a steam turbine generator set boiler, which includes the following steps:

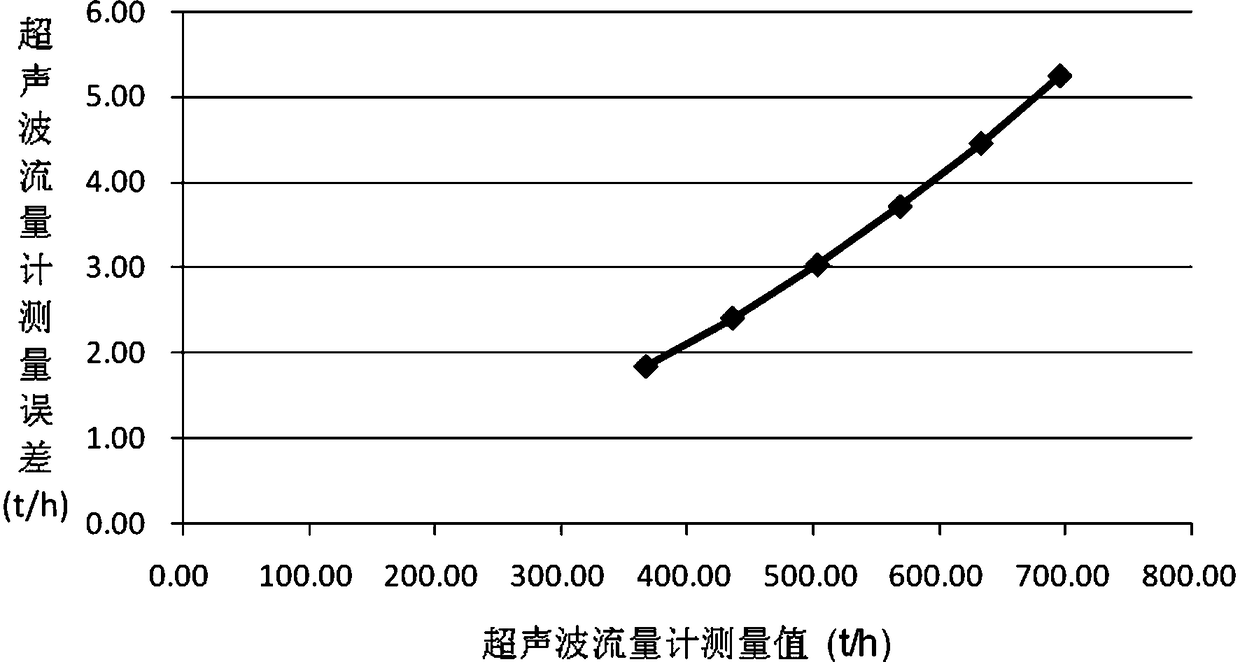

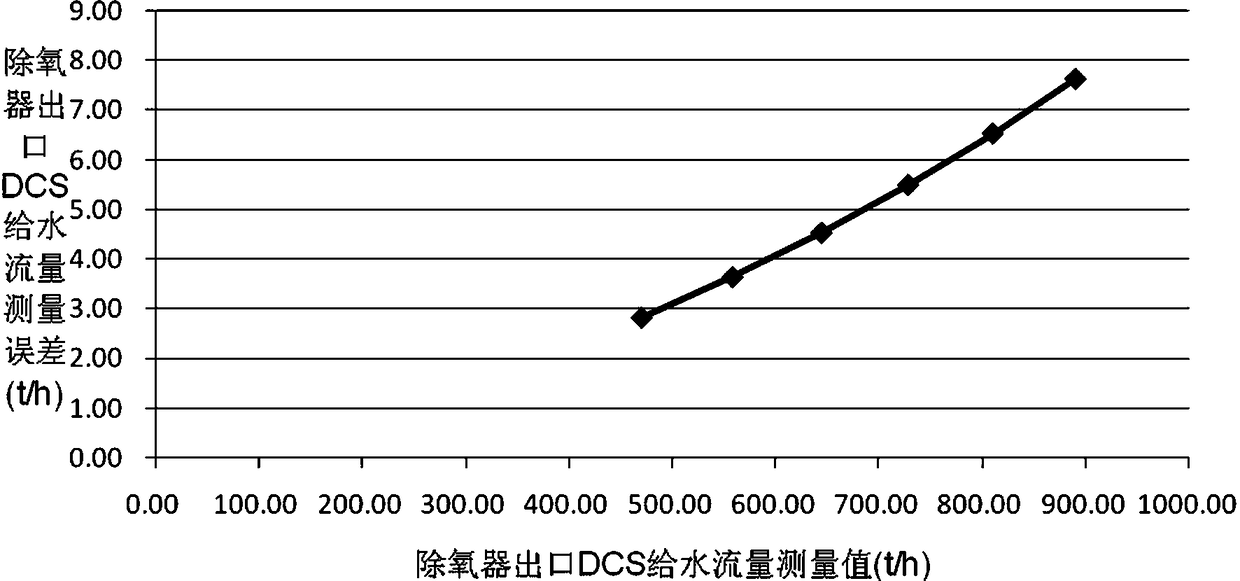

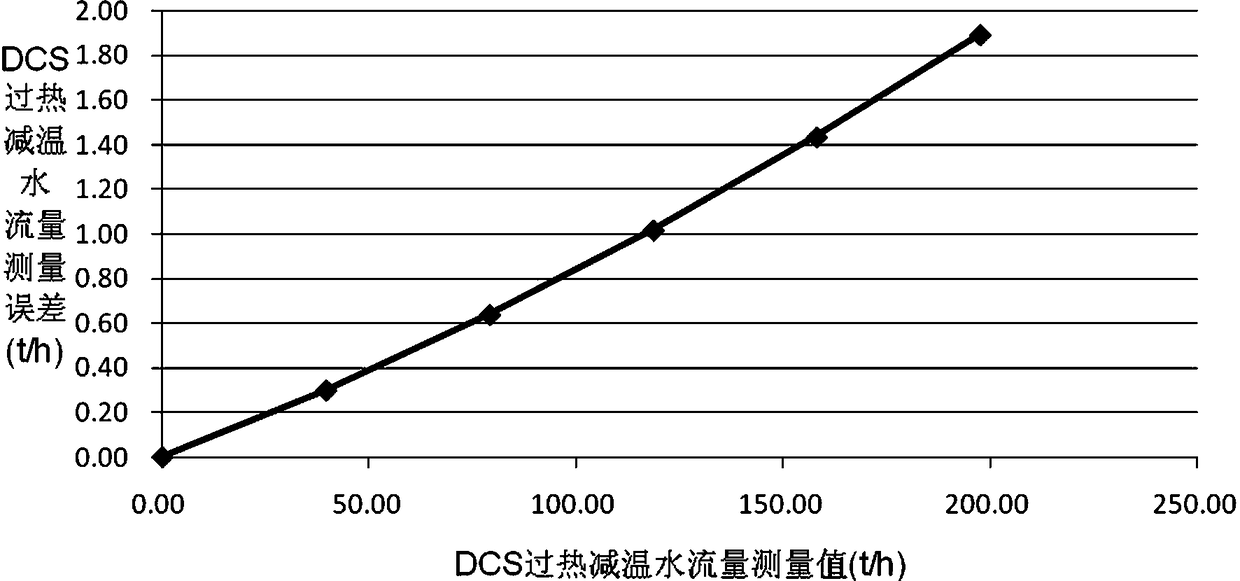

[0097] Step 1: Use a verified ASME flow nozzle on an A steam turbine generator set with an ASME flow nozzle and a rated capacity of 300MW. The flow of condensate at the inlet of the deaerator is used as the object to measure the data of the high-temperature ultrasonic flowmeter. Calibration; during calibration, the change in the condensate flow at the inlet of the deaerator should cover the 50% to 100% load range of the turbine generator set, and every 10% load change is a calibration condition, a total of 6 calibration conditions , The average value of each measurement condition is shown in Table 1:

[0098] Table 1 Calibration measurement data of condensate flow at the inlet of the deaerator

[0099]

[0100]

[0101] Set 6≥i≥1 to keep the condensate flow at the inlet of the deaerator stable under the i-th operating load, record data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com