A Fault Detection Method and Diagnosis Method for Non-stationary Process of Large Coal-fired Generating Units

A technology for generating sets and fault diagnosis, which is applied in the testing, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

[0063] Large-scale coal-fired power generation is a typical non-stationary process, and some of the variables have obvious non-stationary characteristics, such as the circulating water pressure of the condenser, the inlet steam pressure of the high-pressure heater, and the condensed water volume at the inlet of the deaerator. The present invention takes Unit 8 of Jiahua Power Plant as an example. The power of this unit is 10,000MW, which is a large-scale coal-fired power generation process, including 159 process variables, which involve pressure, temperature, water level, flow rate, etc.

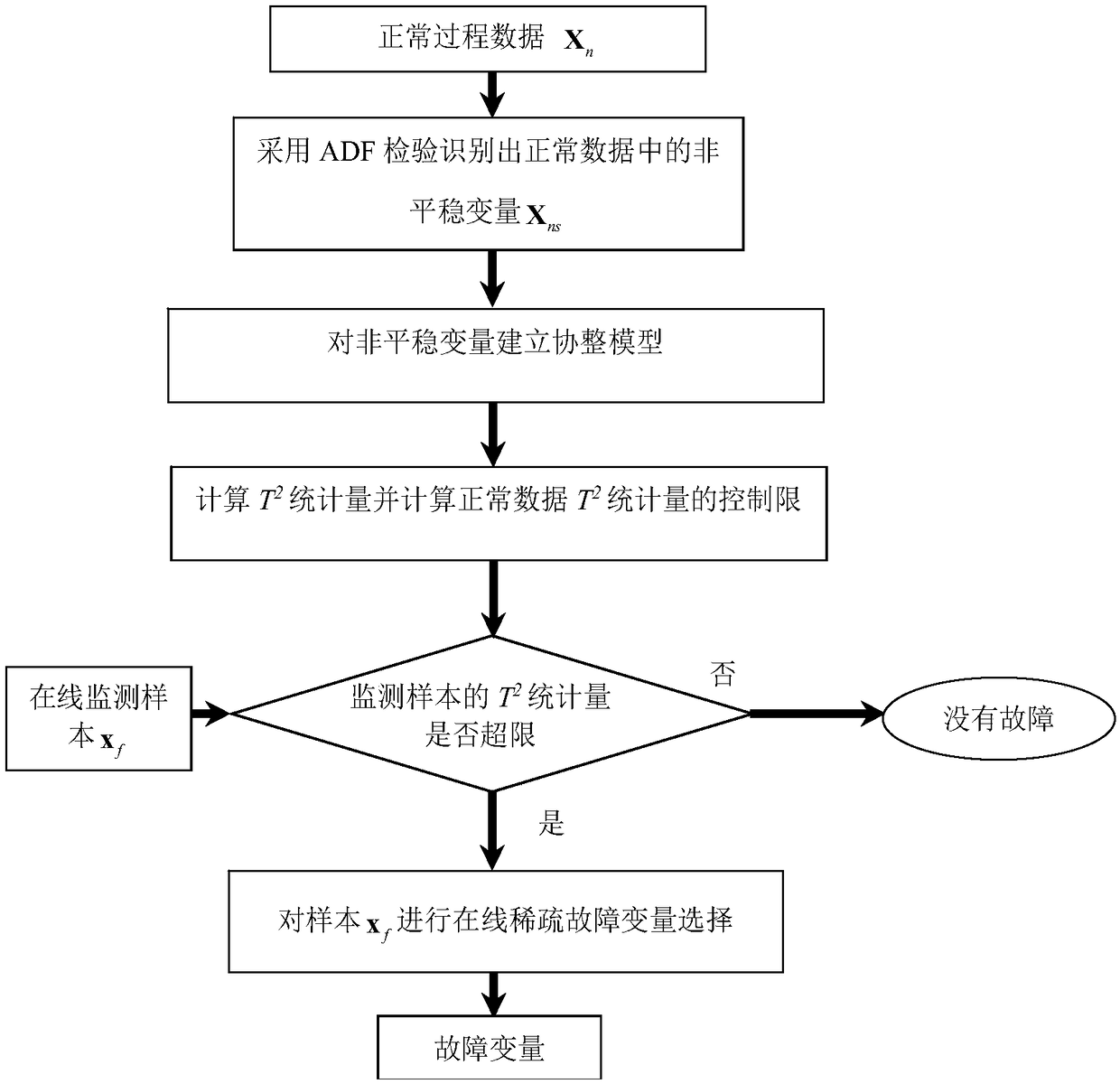

[0064] Such as figure 1 As shown, the present invention is a fault detection and online diagnosis method for the non-stationary process of large-scale coal-fired generating units combined with cointegration analysis and sparse variable selection, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com