A transformer winding mold

A technology of winding molds and transformers, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of reducing production costs and waste of molds, and achieves the goal of reducing production costs, solving waste of molds, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

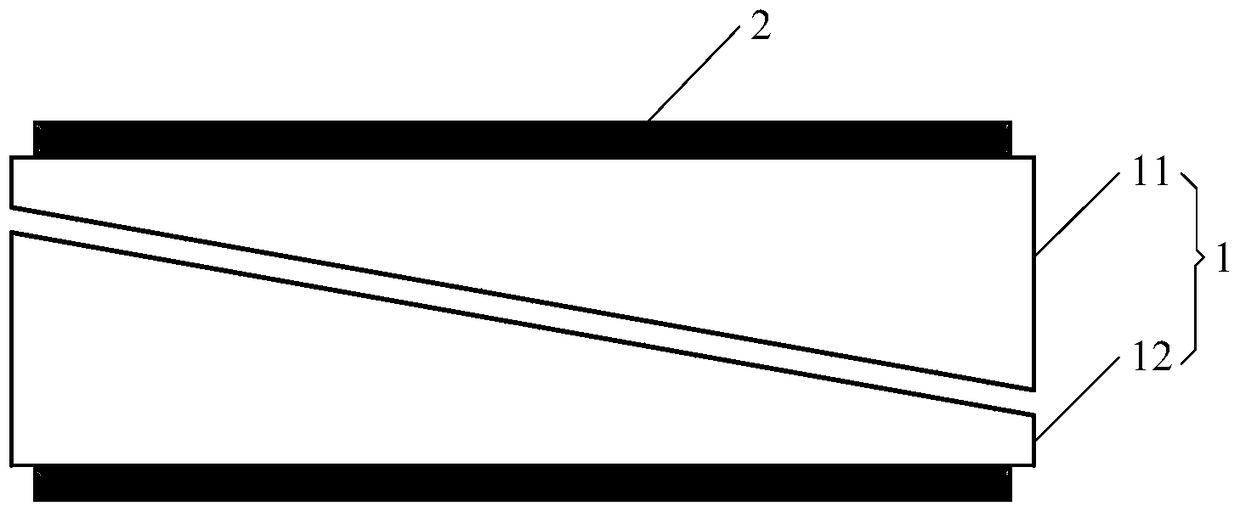

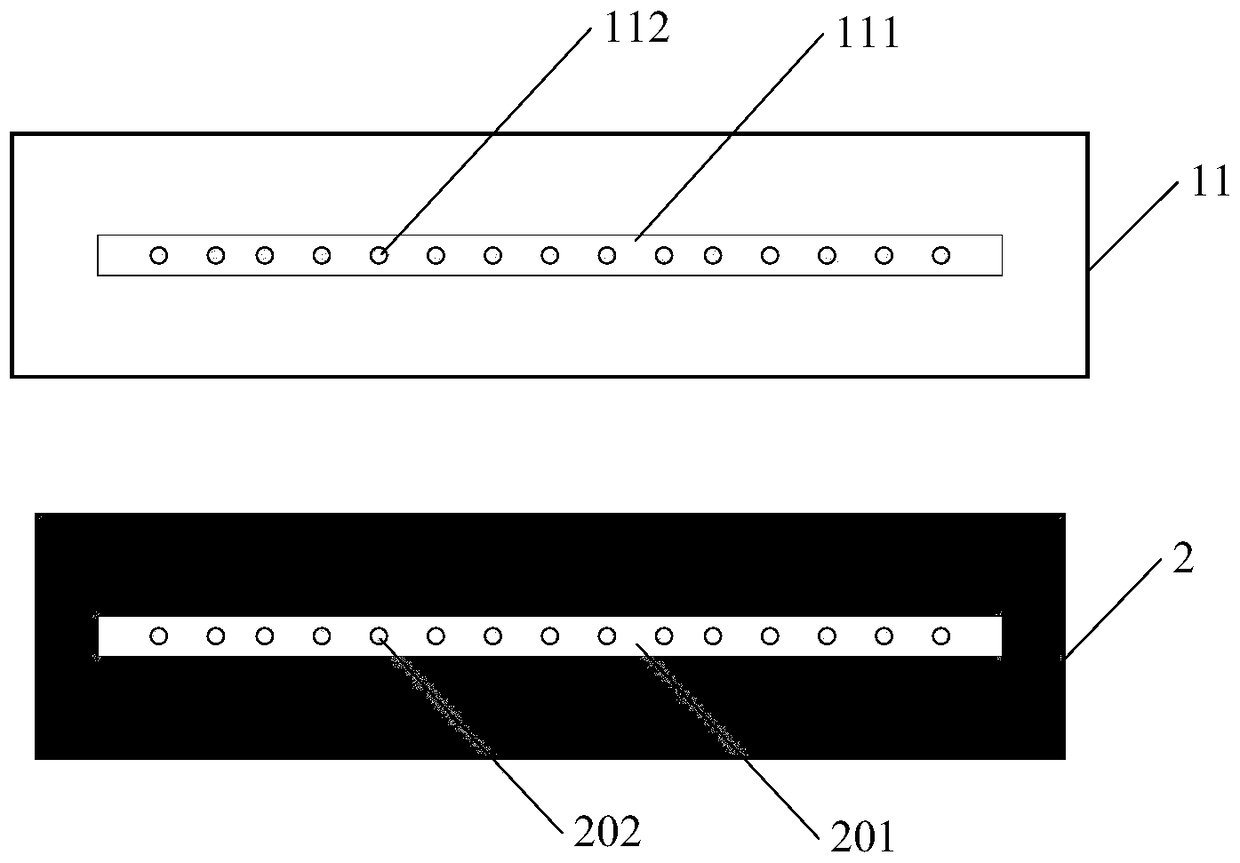

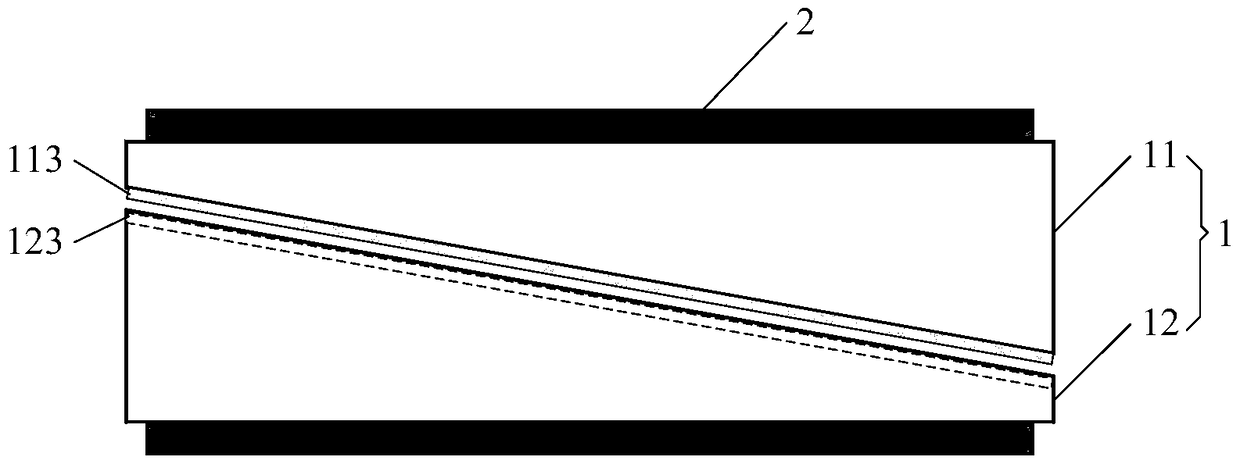

[0022] Such as figure 1 , 2 As shown, it is a transformer winding mold in the present invention, including a basic mold 1 and an expansion plate 2. The basic mold 1 is composed of an upper mold 11 and a lower mold 12 that cooperate with each other. surface, the other surface corresponding to the mating surface is the base surface, and the expansion plate 2 is arranged on the base surface of the upper mold 11 and / or the lower mold 12 .

[0023] The basic mold 1 is made of metal material, which has better knock resistance and longer service life.

[0024] The expansion board 2 is made of an electrical board, the price of the material is low, and the strength meets the needs of production, which reduces the production cost.

[0025] The width of the expansion board 2 is equal to the width of the base mold 1, and the length is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com