A weighing mixer

A mixer and weighing technology, which is applied to mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve problems such as large labor loss, waste, and irregular measuring methods, so as to solve waste and speed up the speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

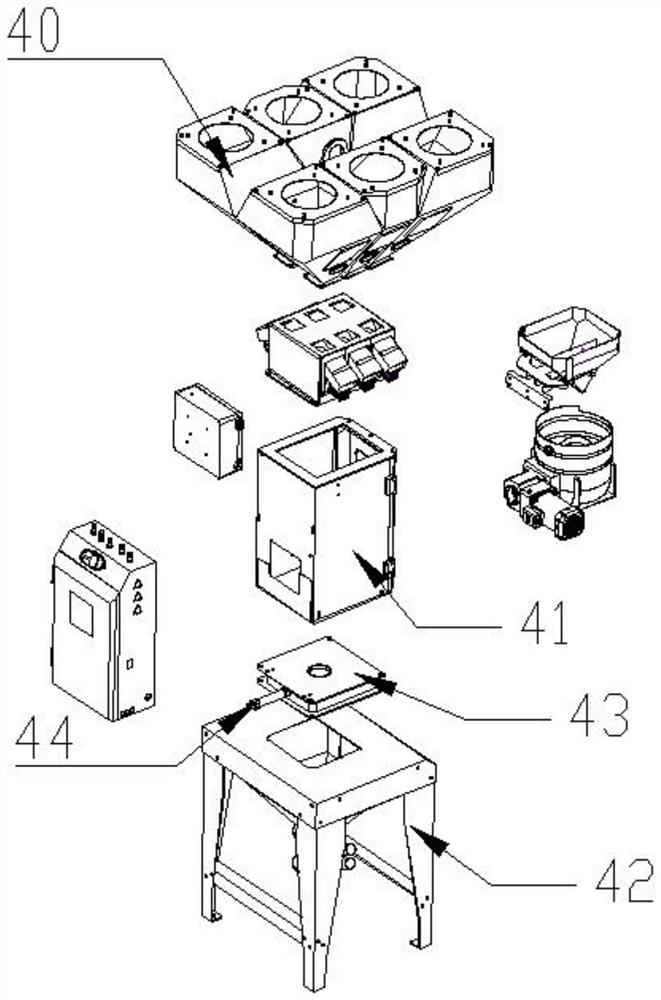

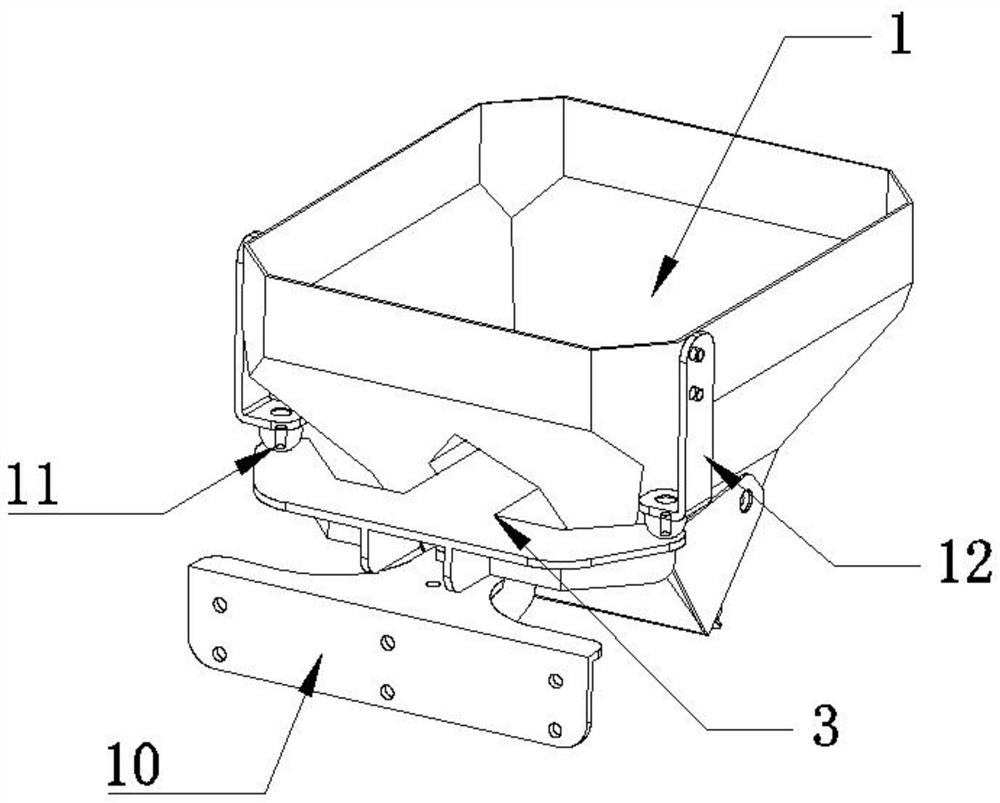

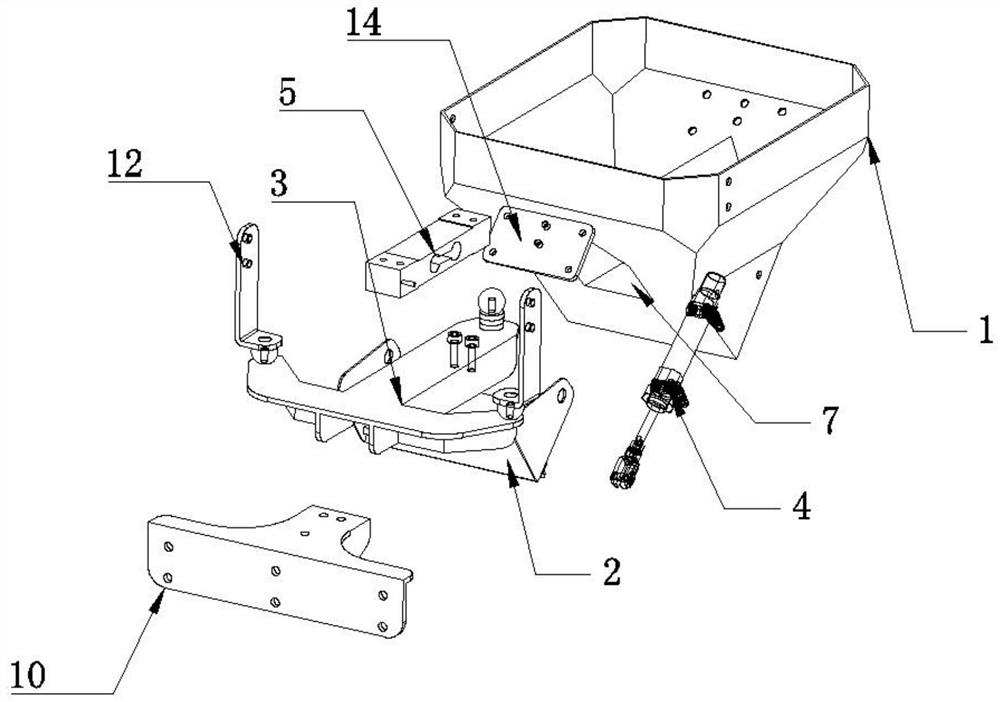

[0046] see Figure 1-15 As shown, the present invention relates to a weighing mixer, including: a weighing device, the weighing device includes a weighing pan 1, a weighing pan material closing plate 2, a weighing pan support frame 3, and a first telescopic cylinder 4 , the first load cell 5, the spacer belt, the surface of the weighing pan 1 is connected to the internal feeding port, and the spacer belt runs through the opposite sides of the weighing pan 1 to divide the weighing pan 1 into two feeding chambers 6, and Both ends of the spacer are openings, and the openings penetrate the inside of the spacer to form a channel 7 for the weighing pan support frame 3 to pass through. There is a weighing pan discharge port 8 corresponding to the blanking cavity 6, the first telescopic cylinder 4 is arranged on the side of the weighing pan 1, and the weighing pan material closing plate 2 cover is arranged on the surface of the weighing pan discharge port 8 and is connected with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com