Device for drying glass powder by utilizing waste heat

A glass powder, waste heat technology, applied in heating devices, drying, dryers and other directions, can solve the problems of energy consumption, reduce energy consumption and production costs, and achieve the effect of reducing production costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

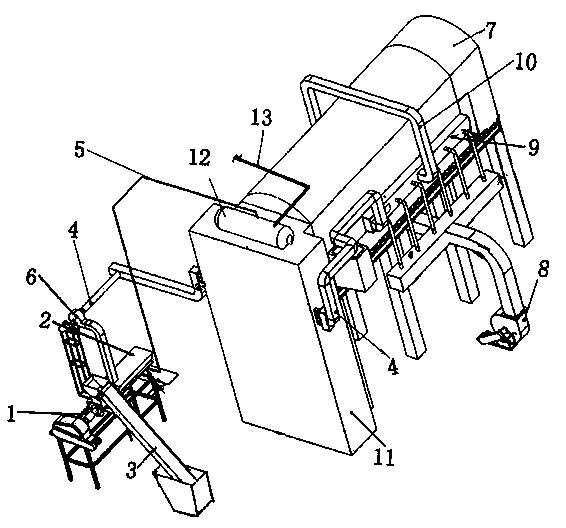

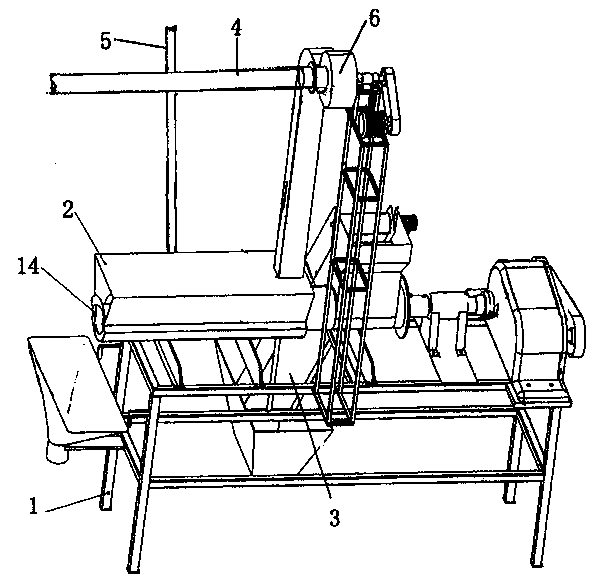

[0012] figure 1 Shown: the high temperature zone on both sides of the melting furnace 7 for melting glass frit is provided with heat absorption boxes 9 respectively, and the heat absorption boxes 9 on both sides are connected through a connecting pipe 10; one side of the heat absorption box 9 is connected to a blower 8 through a blowing pipe , The heat absorption box 9 is provided with a hot air pipe 4 connected to the drying chamber 2 above the LED material drying equipment rack 1; a tail gas heat exchange chamber 11 is provided at the tail gas discharge end of the melting furnace 7, and the tail gas heat exchange A steam-water flow pipe 12 is provided above the chamber 11. The steam-water flow pipe 12 is equipped with a water supply pipe 13 and a steam discharge pipe 5. The outer end of the steam discharge pipe 5 leads into the steam interlayer on the inner and outer circumferences of the drying chamber 2. An induced draft fan 6 is installed in the connection with the drying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com