Three-mode motor and control method thereof

A three-mode, mode-based technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of high speed, low efficiency, high reliability requirements of the controller, abnormal drag, etc., and achieve the effect of high power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

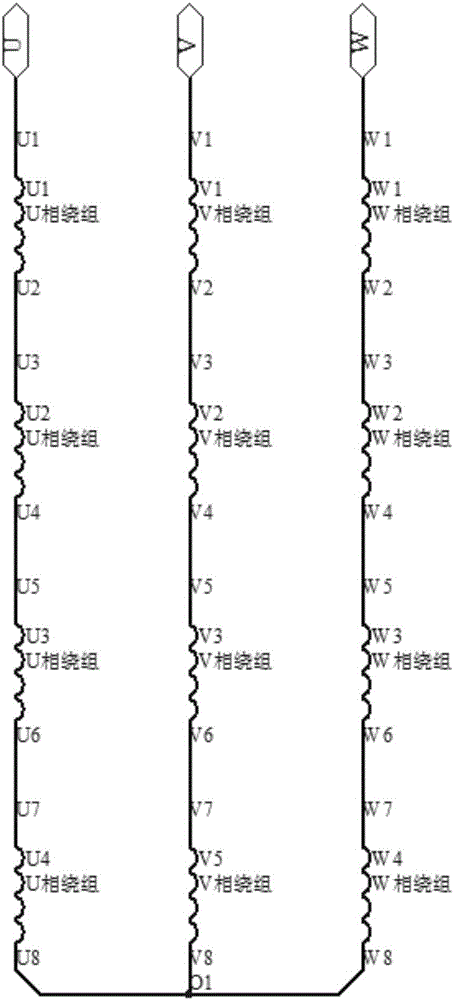

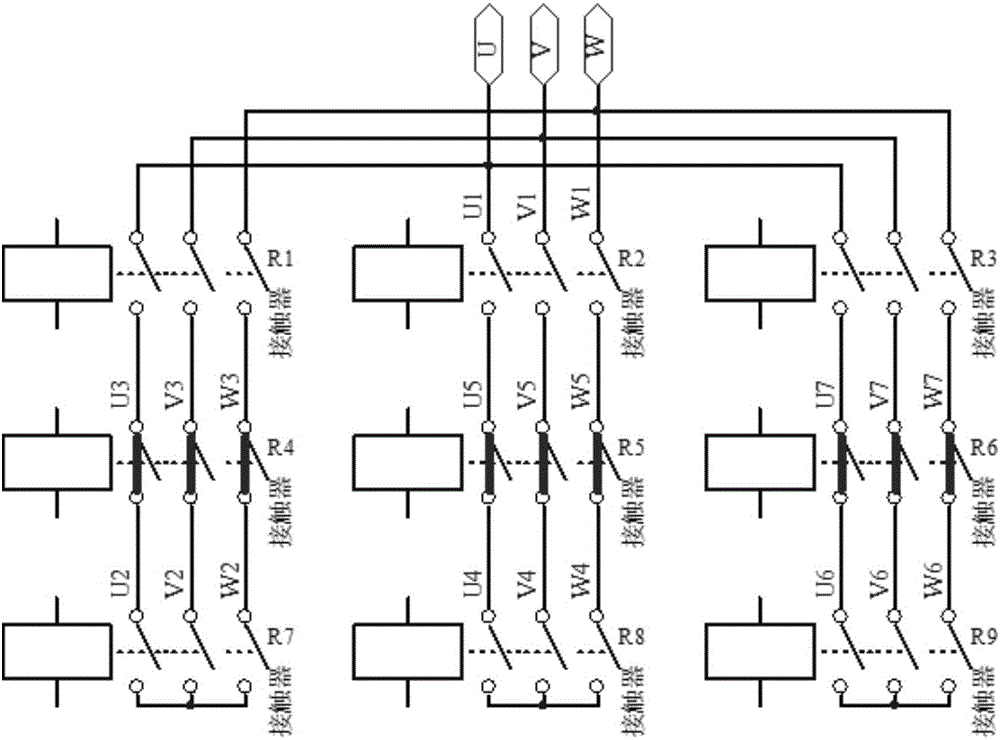

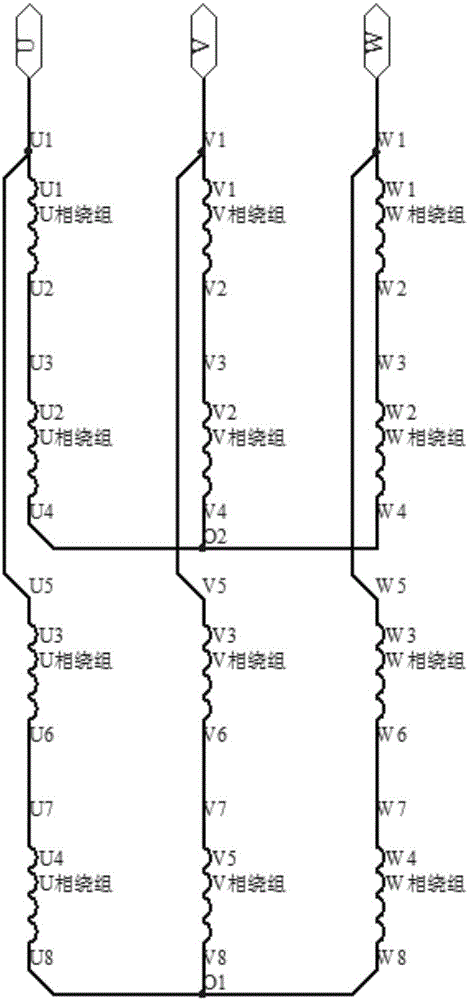

[0031] The three-mode motor of the present invention adopts a three-phase permanent magnet motor, and changes it into a four-winding motor. The motor is designed with each phase winding, and is designed to have 4 windings with the same number of turns, that is, the number of turns of the four windings of the same phase is the same, and the same phase The induced voltage waveform and phase of the four windings are the same.

[0032] The three-mode motor is connected to the three-phase winding of the three-phase power supply in a star connection. Each phase winding unit of the three-phase winding is composed of four windings with the same number of turns. When the motor operates in low-speed mode, each phase winding unit The four windings of each phase are connected in series. When the motor is running in the medium speed mode, the four windings of each phase winding unit are connected in parallel after being connected in series. Each phase forms two star center points. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com