A capillary driven flat plate evaporator fluid circuit

A fluid circuit and evaporator technology, which is applied in the field of cryogenic heat transfer devices to solve the problems of miniaturization and supercritical start-up, is conducive to miniaturization design, and reduces the quality of liquid work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

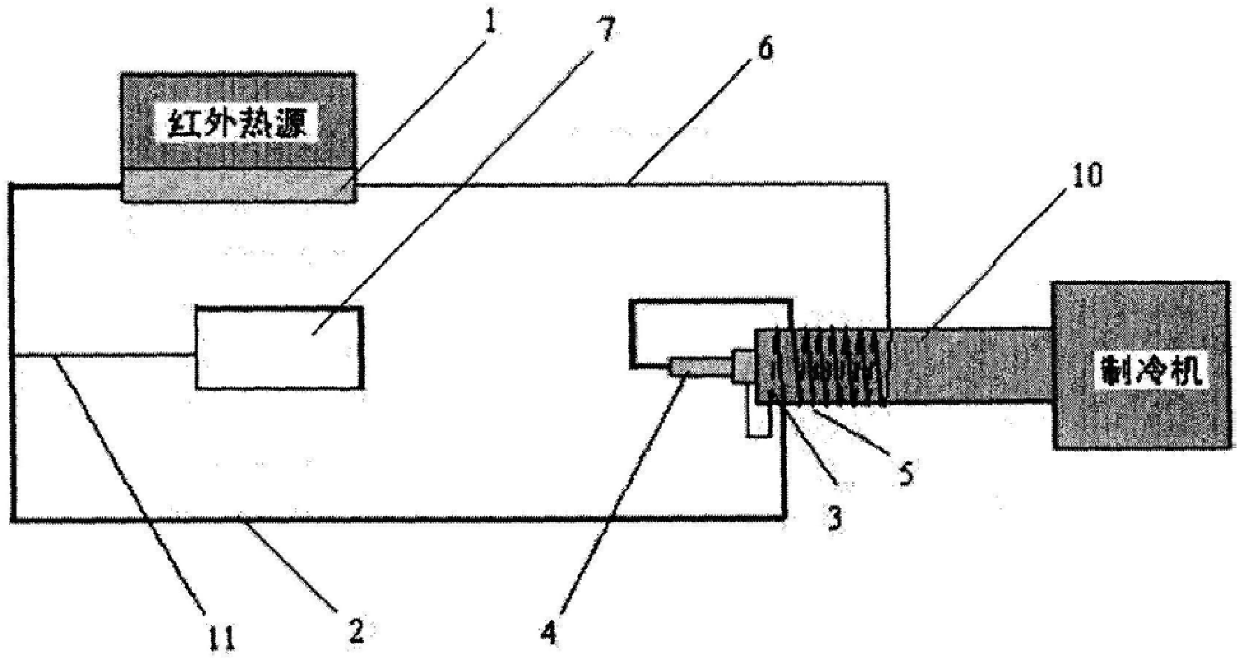

[0018] The present invention provides capillary force-driven plate evaporator fluid circuit, as shown in Figure 1.

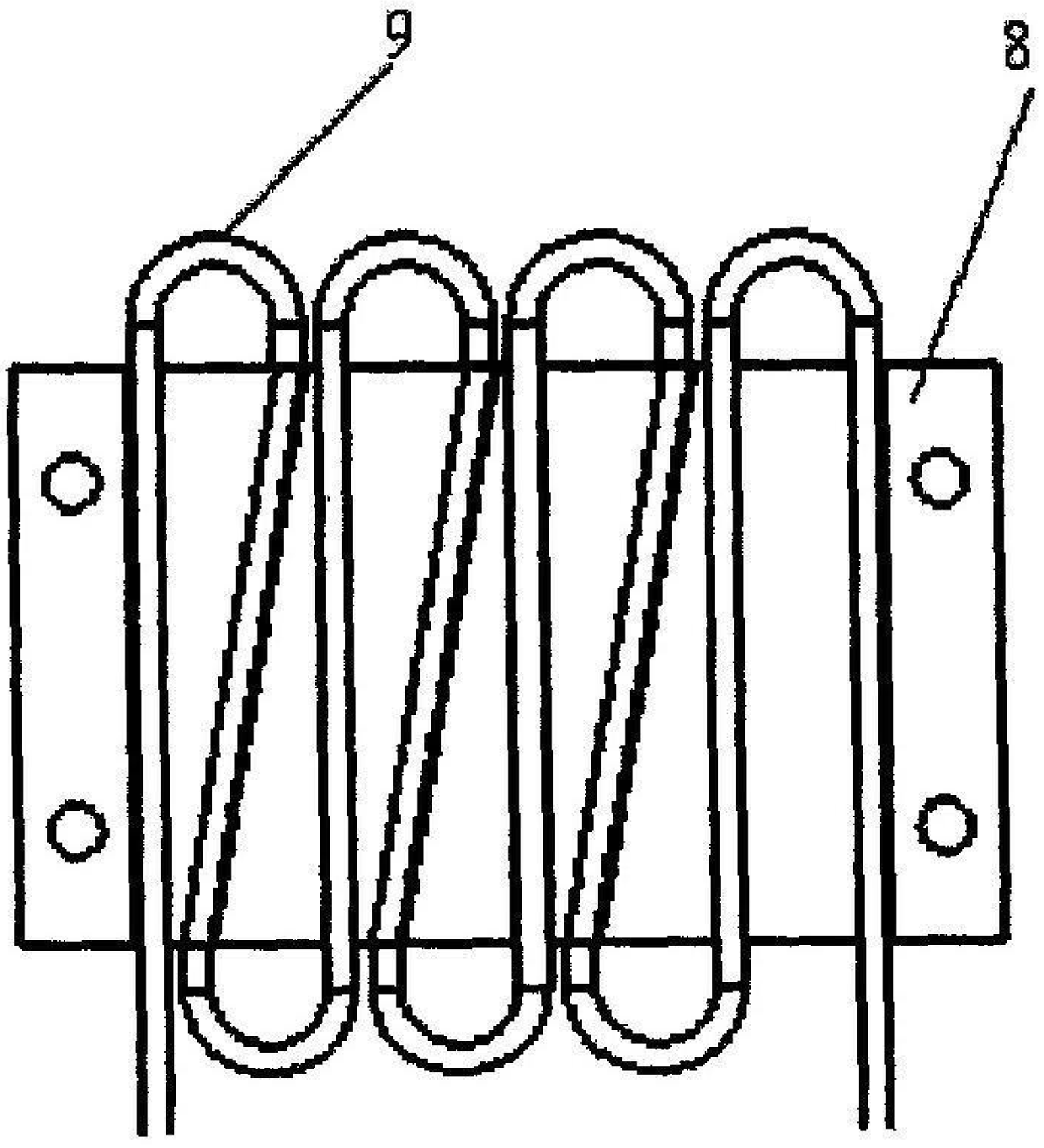

[0020] The auxiliary condensation pipe 3 and the main condensation pipe 5 are brazed in the groove of the condensation column 10 to increase the heat transfer effect. steam line 2

[0023] The plate evaporator 1 is thermally coupled with an infrared heat source, and the condensation column 10 is coupled with a refrigerator. Capillary evaporator 4 with condensation

[0024] The capillary evaporator in this embodiment can also be connected to a liquid reservoir.

[0026] The plate evaporator 1 is coupled with an infrared heat source, which can collect heat from the heat source. Condensation column 10 is coupled with refrigerator, can

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com