Efficient vegetable basin

A vegetable washing basin and high-efficiency technology, applied in the field of vegetable washing basins, can solve problems such as reducing the cleaning effect of vegetables and fruits, and achieve the effect of improving work efficiency and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

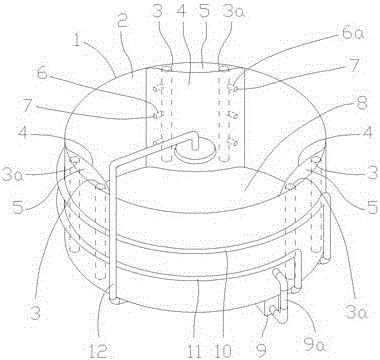

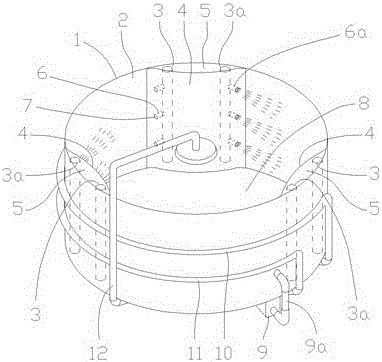

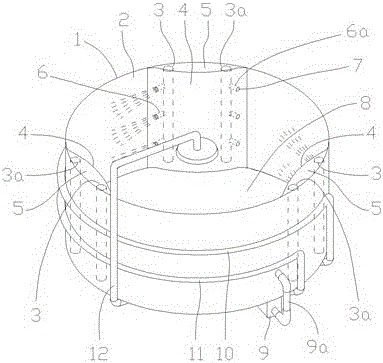

[0010] Such as Figure 1 to Figure 3 As shown, the bottom wall 8 of the dishwashing basin body 1 is provided with a drain hole (not shown in the figure), and the inner wall 2 of the dishwashing basin body 1 is provided with three protruding parts 5 in the circumferential direction, and the three protruding parts 5 are arranged according to Equidistantly distributed, the outer side of the protruding part 5 is provided with an arc-shaped side wall 4, and the left and right sides of the inner cavity of the protruding part 5 are provided with a first vertical tube 3 and a second vertical tube 3a, and the upper and middle parts of the second vertical tube 3a and the lower part are each provided with a laterally protruding second nozzle 6a, the second nozzle 6a protrudes clockwise, and the outer end opening 7 of the second nozzle 6a is on the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com