Stirrup die for automatic forming equipment for steel bar bending hoops

A technology of automatic forming and steel bar bending hoop, applied in the field of construction machinery, can solve the problems of high labor intensity, high production cost, slow speed, etc., and achieve the effect of improving the forming speed and quality, reducing labor intensity and reducing pressing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

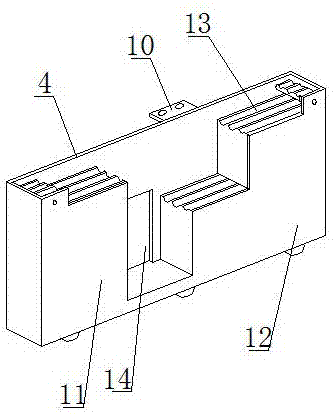

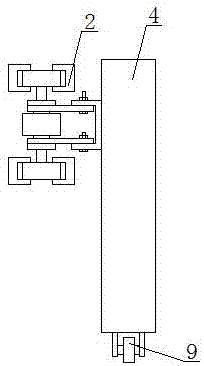

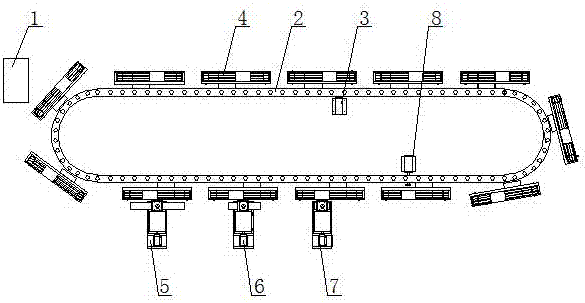

[0020] The stirrup die used for the automatic forming equipment for steel bar bending hoops is composed of a die body 4, the die body 4 is a rectangle, the bottom of the die body 4 is provided with a walking roller 9, and the upper end of the die body 4 is provided with There are lugs 10 for connecting with the drive rail chain 2 so as to move around the frame with the drive rail chain 2 during work.

[0021] Stepped left forming workbench 11 and right forming workbench 12 are arranged on the die body 4 at intervals. The left molding workbench 11 is a two-layer workbench. The right forming workbench 12 is a three-layer workbench. A plurality of stirrup grooves 13 are respectively juxtaposed on the workbenches of each layer to place steel bar straight bars during work and to avoid rolling of semi-finished stirrups during work. The lower end of the die body 4 between the left forming workbench 11 and the right forming workbench 12 is provided with a discharge hole 14, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com