A wing leading edge capable of improving aircraft anti-bird strike performance

A technology for wing leading edge and bird strike, applied in wings, aircraft parts, motor vehicles, etc., can solve problems such as front beam structure damage, skin tearing, wing leading edge deformation, etc., and achieve bird strike resistance. Improve, increase the structural rigidity, protect the effect of the beam web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

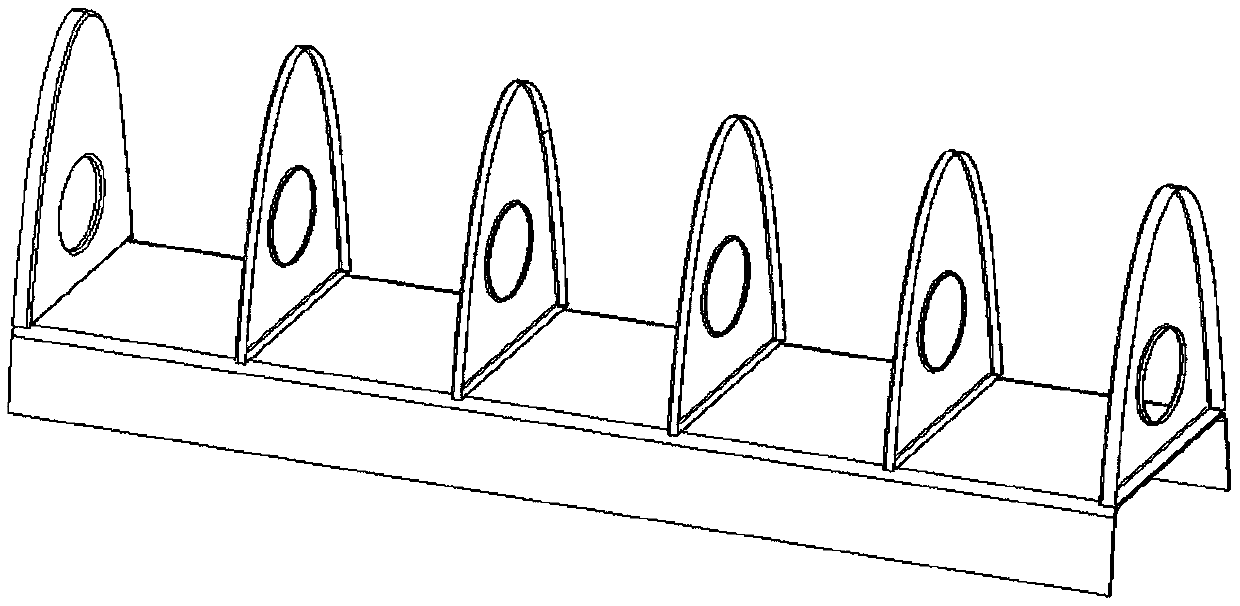

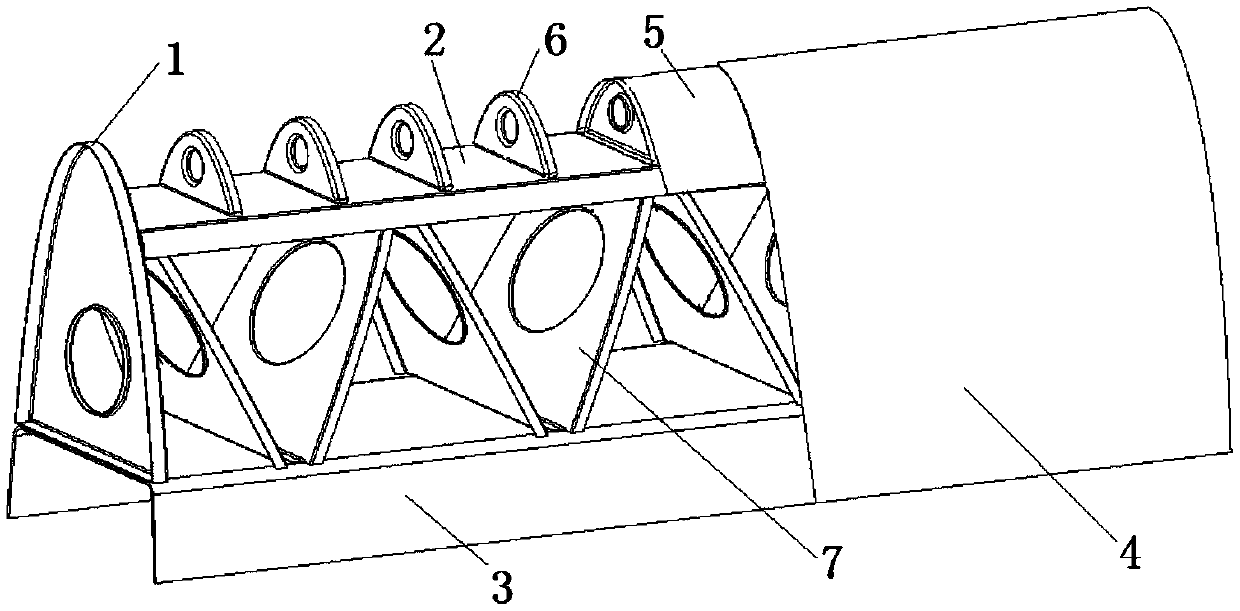

[0030] This embodiment is used for the anti-bird strike wing leading edge of a certain type of aircraft, including wing leading edge skin 4, additional skin 5, front beam 3, small front beam 2, a plurality of front ribs 6, a plurality of rear Rib 7 and two side ribs 2. in:

[0031] The two side ribs 1 are respectively fixed on the upper surfaces of the two ends of the front beam 3 . The small front beam 2 is located on the upper part of the two side ribs, and the two ends of the small front beam are respectively riveted with the inner surfaces of the two side ribs. The rear ribs 7 are arranged between the upper surface of the front beam 3 and the lower surface of the small front beam 2, and each rear rib is inclined so that a "V" shape or an inverted shape is formed between two adjacent rear ribs. "V"-shaped included angle; the angle of said included angle is 60°. A plurality of front ribs 6 are evenly distributed on the upper surface of the small front beam 2 . The vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com