A flocculant premixing device for washing machine and washing machine

A flocculant and washing machine technology, applied in the field of washing machines, can solve the problems of long total washing time of washing machines, increase of equipment parts, increase of production costs, etc., and achieve the effects of being suitable for popularization and use, increasing flocculation rate, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

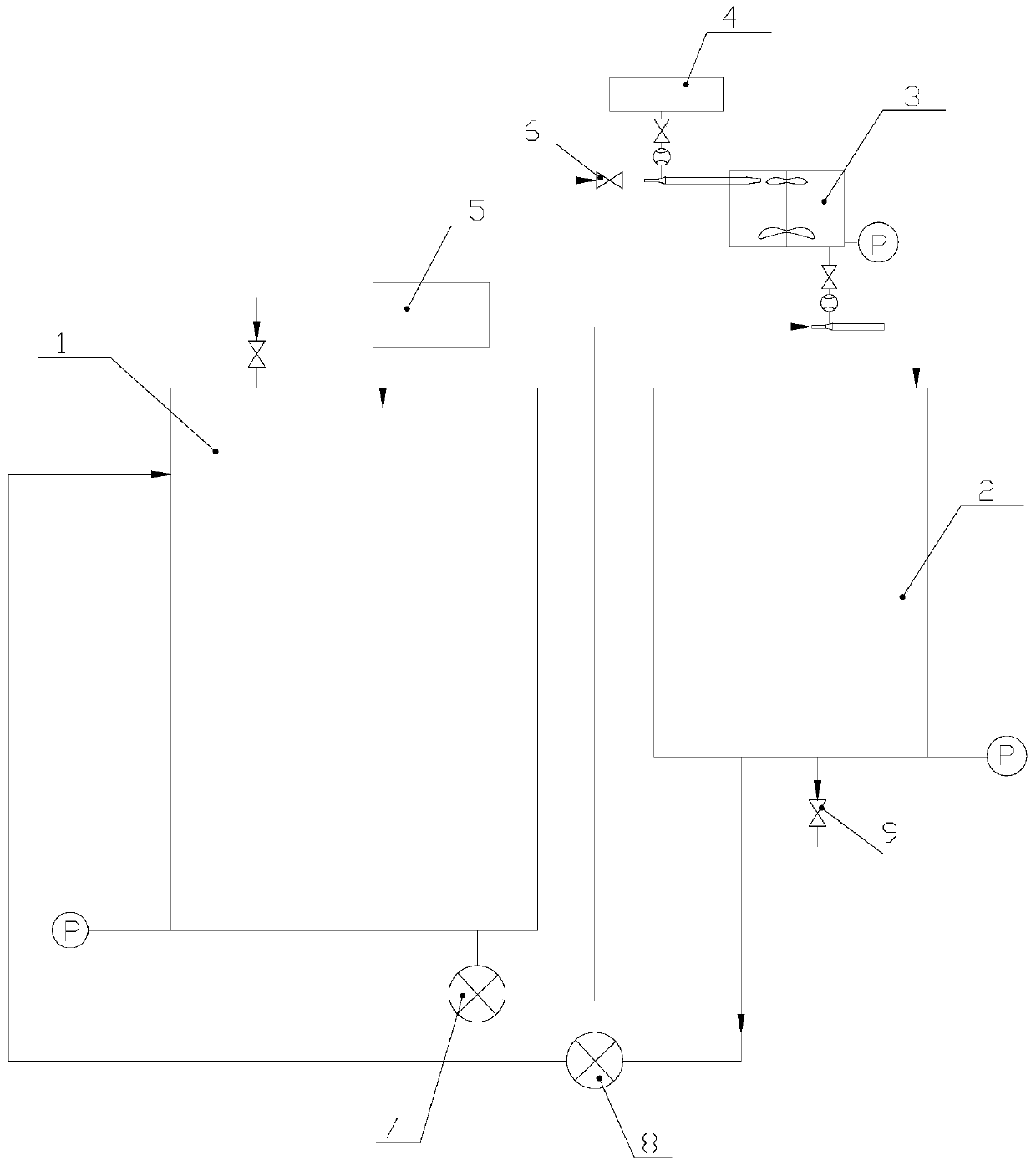

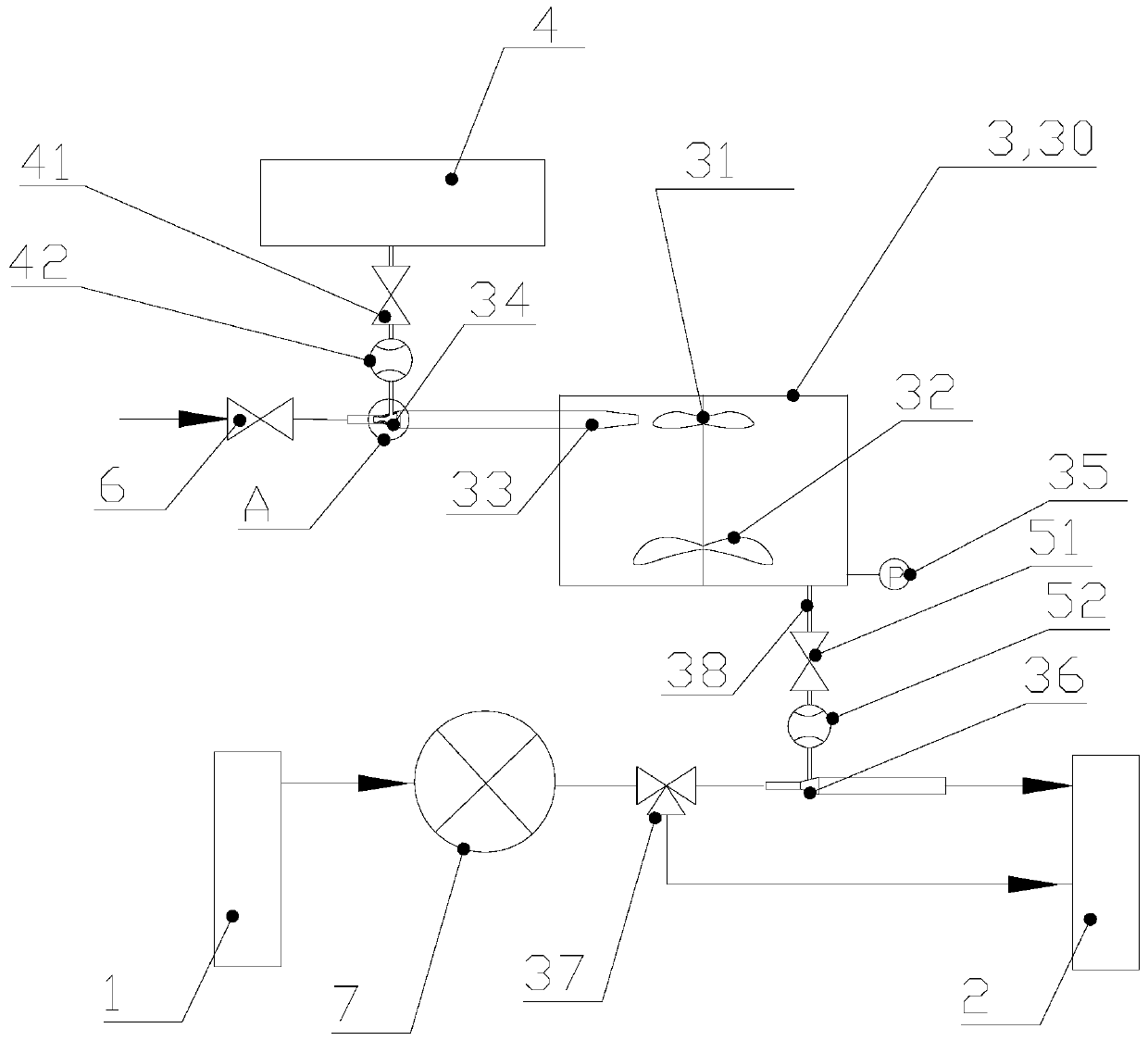

[0037] Such as figure 2As shown, in this embodiment, the flocculant premixing device 3 includes a premixing chamber 30; the premixing chamber 30 is provided with a coaxial driving wheel 31 and a stirring wheel 32, and the premixing chamber 30 The liquid inlet is set corresponding to the driving wheel 31, so that the water is sprayed to the driving wheel 31 to drive the driving wheel 31 and the stirring wheel 32 to rotate together. Therefore, the flocculant solvent in the flocculant premixing device 3 is further stirred by the stirring wheel 32, so that the mixing uniformity of the solvent is further improved; at the same time, the influent water flow is used to directly provide the rotational driving force, which simplifies the structure and saves the cost .

[0038] In this embodiment, the driving wheel 31 and the stirring wheel 32 are coaxially arranged up and down, the liquid inlet of the premixing chamber 30 and the driving wheel 31 are arranged in the same plane, and th...

Embodiment 2

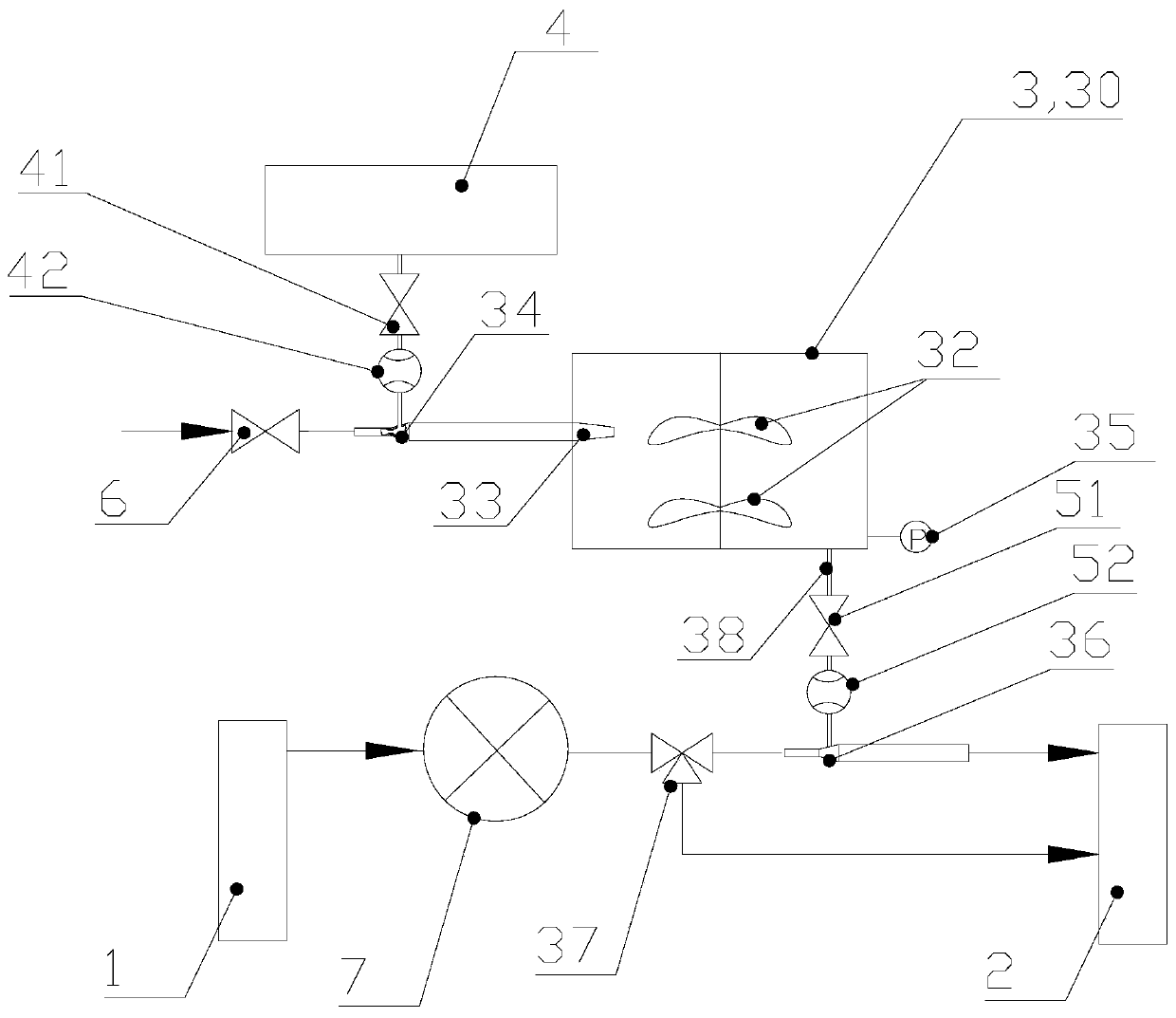

[0047] The difference between this embodiment and the first embodiment above is that: image 3 with Figure 5 As shown, only a stirring wheel 32 is provided in the pre-mixing chamber 30, and the liquid inlet of the pre-mixing chamber 30 is set corresponding to the stirring wheel 32, so that the incoming water is sprayed to the stirring wheel 32 to drive the stirring wheel 32 to rotate, and the same It can realize the use of water to drive the stirring device to work, so as to achieve the purpose of stirring the mixed solvent of flocculant and tap water.

[0048] In this embodiment, it can be as Figure 5 As shown, only one stirring wheel 32 is set in the premixing chamber 30; image 3 As shown, a plurality of coaxial stirring wheels 32 are set, and the liquid inlet of the premixing chamber 30 is set corresponding to one of the stirring wheels 32, so that the water spray is directed at the blades of the corresponding stirring wheels 32 to drive each stirring wheel co-rotate....

Embodiment 3

[0050] The difference between this embodiment and the above-mentioned facility example 1 is that: Figure 4 As shown, the premixing chamber 30 is provided with a coaxially arranged stirring wheel 32 and a driving wheel 31, the common axes of the driving wheel 31 and the stirring wheel 32 are arranged horizontally, and the liquid inlet of the premixing chamber 30 is connected to the driving wheel 31 is located in the same vertical plane, and the axis of the liquid inlet is arranged tangentially to the drive wheel, which can also realize the rotation of the stirring wheel and achieve the purpose of stirring the flocculant and tap water. Preferably, the liquid inlet of the pre-mixing chamber 30 sprays water flow from top to bottom, so that the water flow is sprayed to the blades of the driving wheel from top to bottom, so as to achieve the purpose of rationally utilizing the falling gravity of the water flow to increase the driving force.

[0051] Of course, in this embodiment, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com