Method for preventing earthquake liquefaction instability of ultrafine tailing heaping upstream method tailing dam

A tailings dam, upstream technology, applied in dikes, buildings, dams, etc., can solve problems such as earthquake liquefaction and instability, and achieve the effect of reducing processing costs, improving stability, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further describe the present invention, a method for preventing the earthquake liquefaction instability of the tailings dam of the upstream method of superfine tailings piled up in the present invention will be described in more detail below in conjunction with the accompanying drawings.

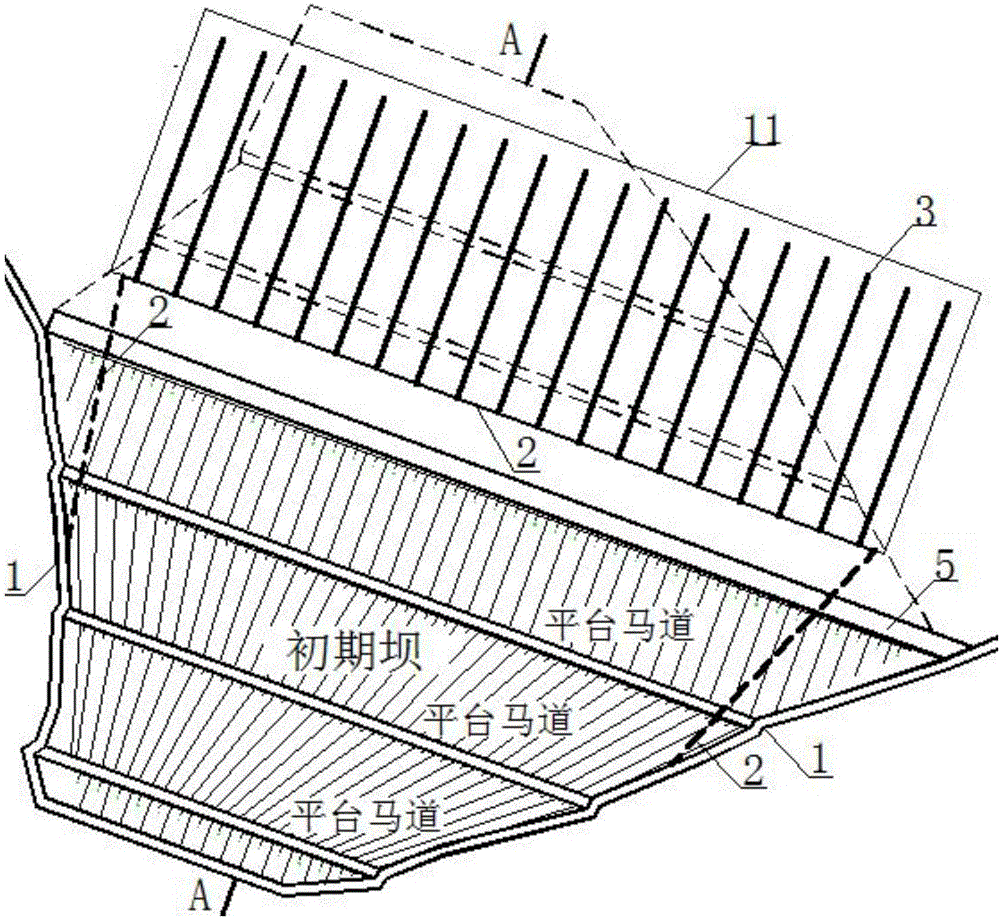

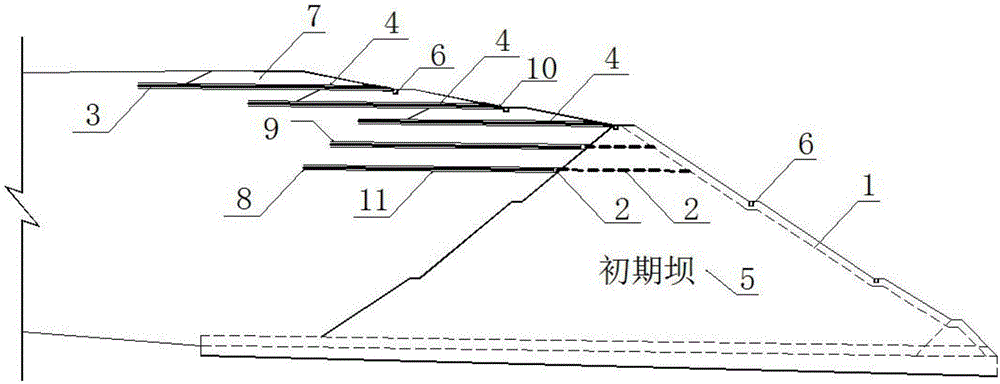

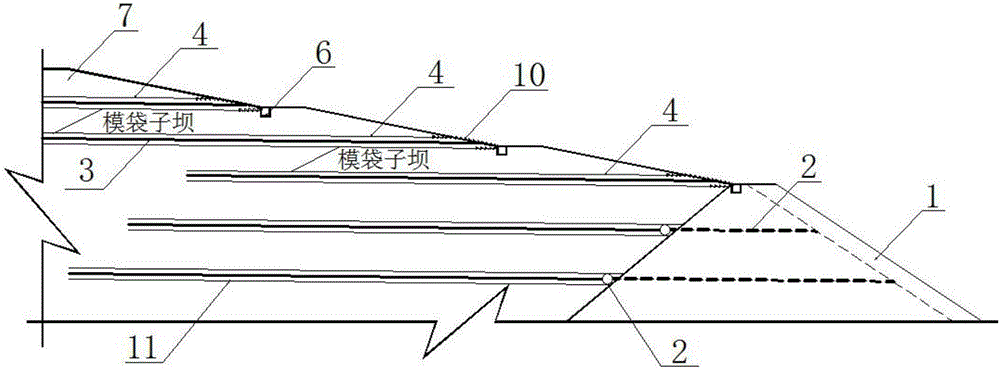

[0039] Depend on figure 1 The first layer of anti-seismic liquefaction medium coarse sand drainage cushion plan layout schematic diagram that the shown inventive method adopts and combines figure 2 , image 3 , Figure 4 , Figure 5 Find out, a kind of method that prevents superfine tailings of the present invention from building upstream method tailings dam earthquake liquefaction instability comprises following process, step:

[0040] The first layer of anti-seismic liquefaction coarse sand seepage drainage layer 8 and the second layer of seismic liquefaction medium coarse sand seepage drainage layer 9 should be constructed together with the initial dam 5. The first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com