Self-circulating cooling oil pump motor

A technology for cooling oil pumps and oil pumps, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve problems such as troublesome cooling methods for motors, obstacles to the development of high-speed motors, and difficulties in popularization, so as to prolong the service life and continuous working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

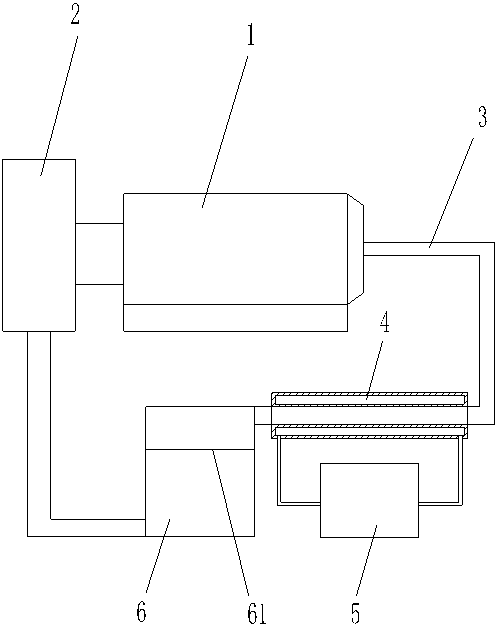

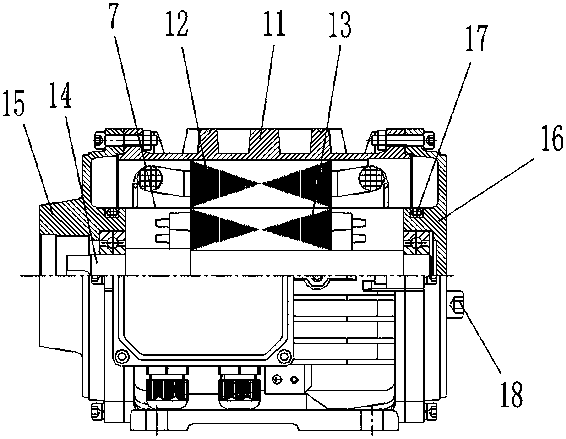

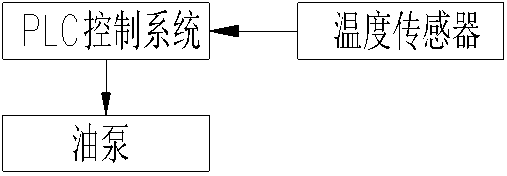

[0015] Embodiment one: if Figure 1~3 As shown, a self-circulating cooling oil pump motor includes a motor body 1, the motor body 1 includes a casing 11, a stator 12 arranged in the casing, a rotating shaft 14 passing through the stator, a rotor 13 wound on the rotating shaft, The front end cover 15 and the rear end cover 16 that are respectively arranged on the two ends of the casing, the bearings of the hinged rotating shaft are all arranged on the said front and rear end covers, and the stainless steel sleeve 7 is connected between the said front and rear end covers, and the stainless steel sleeve The stator is isolated from the rotor, the front end cover is provided with an oil pump 2, and the front end cover is also provided with a channel connecting the inside of the motor and the oil outlet of the oil pump, and the rear end cover is provided with an oil outlet 18. The oil outlet is connected to the oil inlet of the oil pump through a pipeline, the pipeline is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com