Absorbent articles having delta E*

An absorbent product, three-dimensional technology, used in medical science, bandages, etc., can solve problems such as reduced absorbency of the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

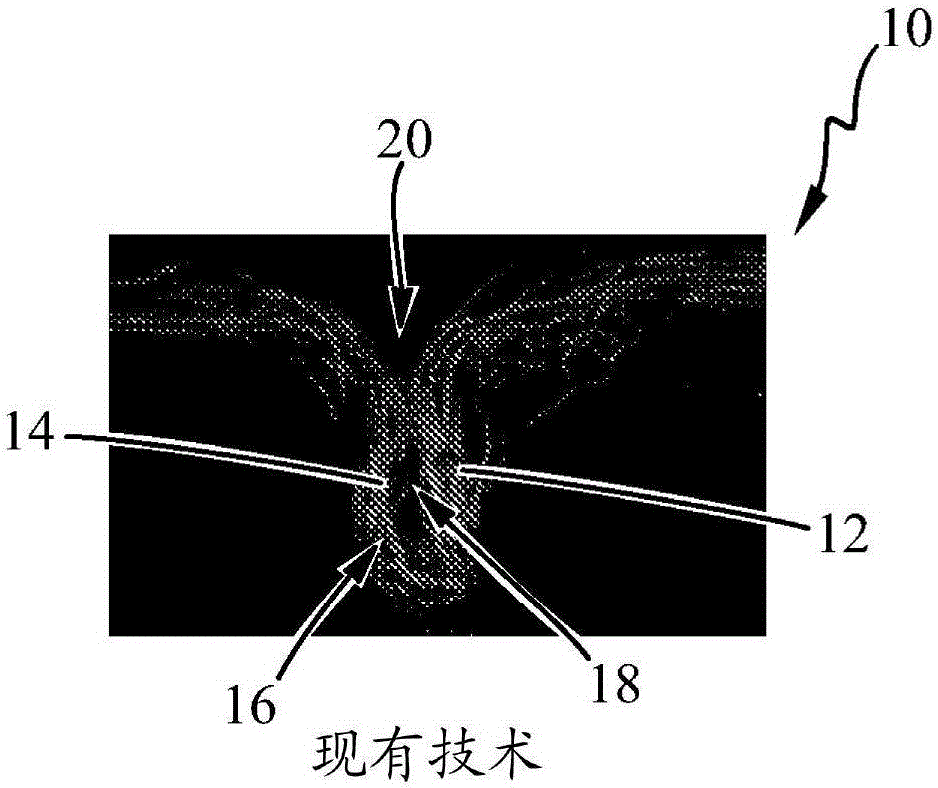

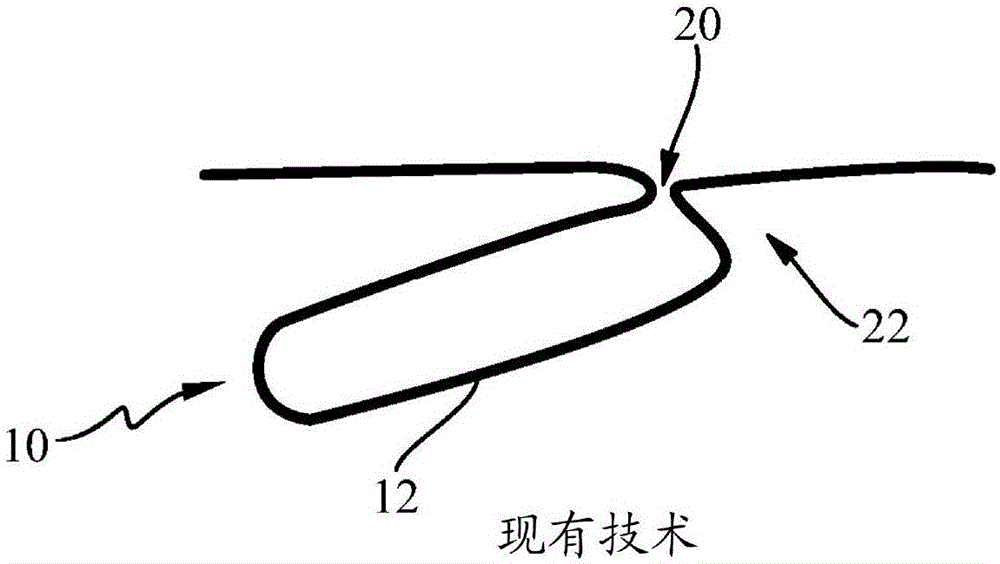

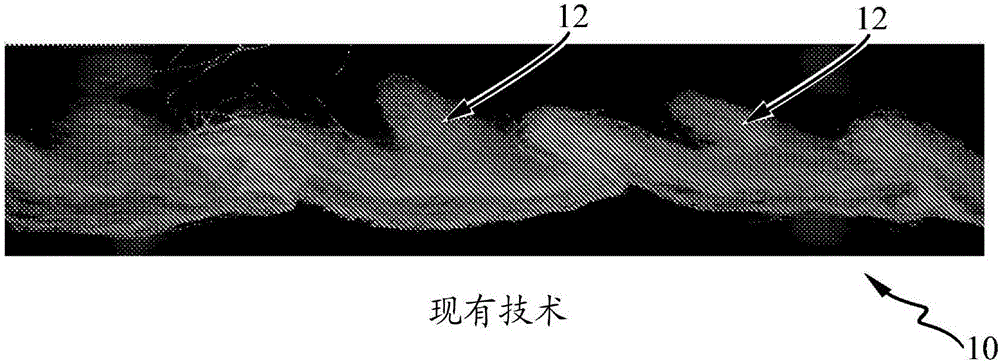

Image

Examples

preparation example Construction

[0177] The methods of making nonwovens described herein may exclude (or be distinguishable from) the following processes: hydroforming (water braiding); hydromolding; use of air jets; rigid versus elastic (e.g., steel / rubber) embossing; and Use the patterned surface against the flat anvil surface. The method may also exclude (or be differentiated from) The Procter & Gamble Company's process for making "Structural Elastic-Like Films" ("SELF" process). The forming member used herein differs from the forming member used in the SELF film formation process (to form the fluted structure (and the tufted structure)) because the SELF teeth typically have relatively small diameter tips and the ridges of the conforming ring roll are only Adjacent to the SELF teeth on the sides, and not the front and rear of the teeth.

[0178] Absorbent

[0179] The three-dimensional nonwoven materials of the present disclosure and their methods of manufacture are discussed above. The use of those t...

Embodiment 1

[0324] Example 1: Single layer

[0325] In Example 1 the material was 50 g / m from Fitesa 2 (gsm) PE / PP sheath / core bicomponent spunbond nonwovens. It was machined by a male / female tooling (shaping member) at a speed of 25 fpm (7.6 meters / minute) at a depth of engagement (DOE) of 0.155 inches (3.94 mm). The teeth on the male tool have a rounded diamond shape similar to that shown in Figure 21 with vertical sidewalls and rounded or rounded edge. The teeth are 0.186 inches (4.72mm) long and 0.125 inches (3.18mm) wide with a CD spacing of 0.150 inches (3.81mm) and a MD spacing of 0.346 inches (8.79mm). The grooves in the conforming concave rolls also have a rounded diamond shape similar to the shape of the convex rolls, with a 0.032-0.063 inch (0.813-1.6 mm) gap between the rolls around the The perimeter of the groove has changed slightly.

Embodiment 2

[0326] Example 2: Two layers

[0327] In Example 2, the material was a composite of two materials glued together using the same hot melt adhesive as described in Comparative Example 1, applied in a spiral pattern. It was machined by the convex / concave tooling described in Example 1 at a speed of 800 feet per minute (fpm) (24.4 meters / minute) and a DOE of 0.155 inches (3.94 mm). The layer of material in contact with the convex roll was a 20 gsm spunbond nonwoven produced by Fitesa comprising 2.5 denier fibers with the blend of PP and PE described in Comparative Example 1 . The layer of material in contact with the gravure roll was a 60 gsm through-air bonded carded nonwoven produced by Beijing Dayuan Non-Woven Fabric Co, LTD (Beijing, China) comprising a PE / PET sheath / core bicomponent of 5 denier fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com