Screw compressor, compressor element and gearbox applied thereby

A screw compressor and compressor technology, which is applied to the components, pump elements, machines/engines, etc. of the pumping device for elastic fluids, can solve the problems of wrong connection and damage of pipelines, and achieves less risk of leakage and processing. The effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

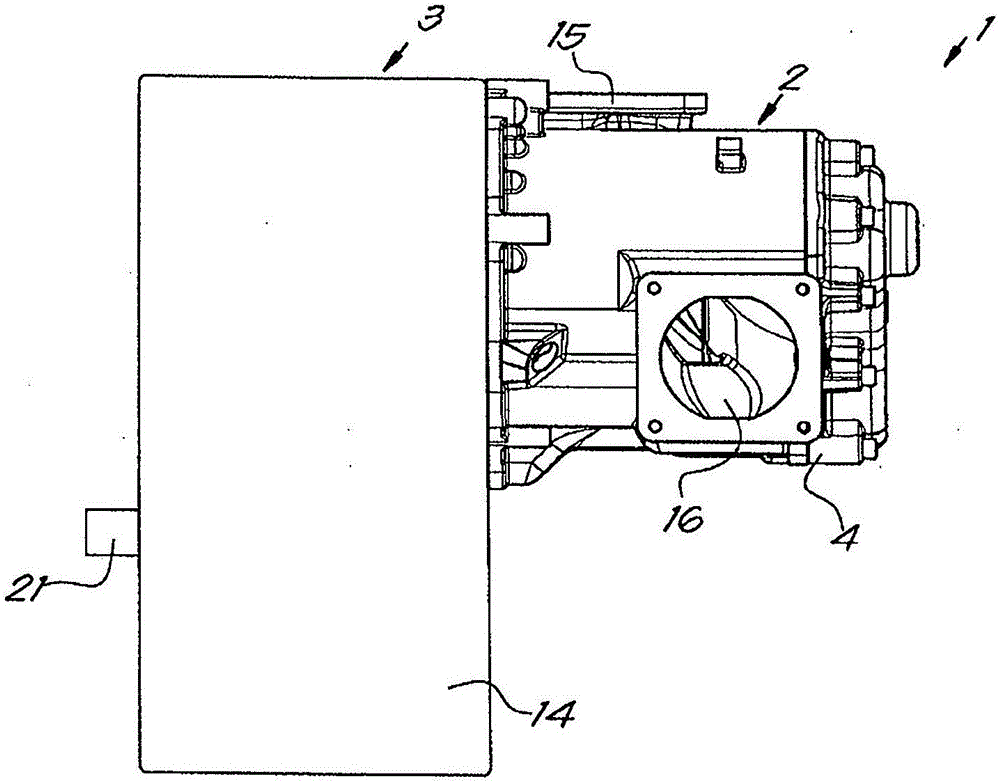

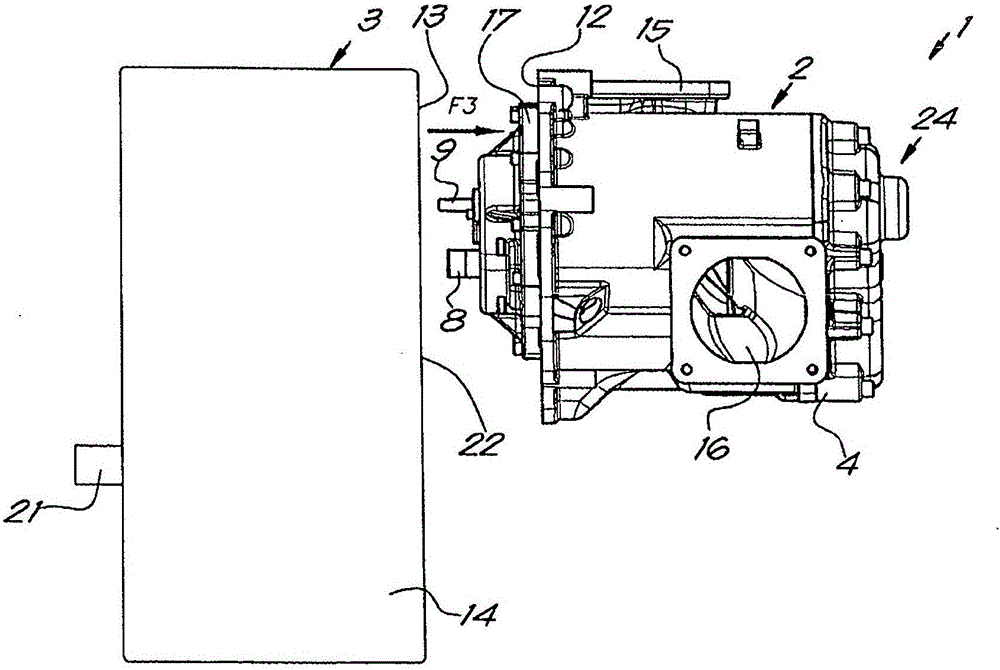

[0045] figure 1 with figure 2 The illustrated oil-free screw compressor 1 comprises a compressor element 2 and a gearbox 3 .

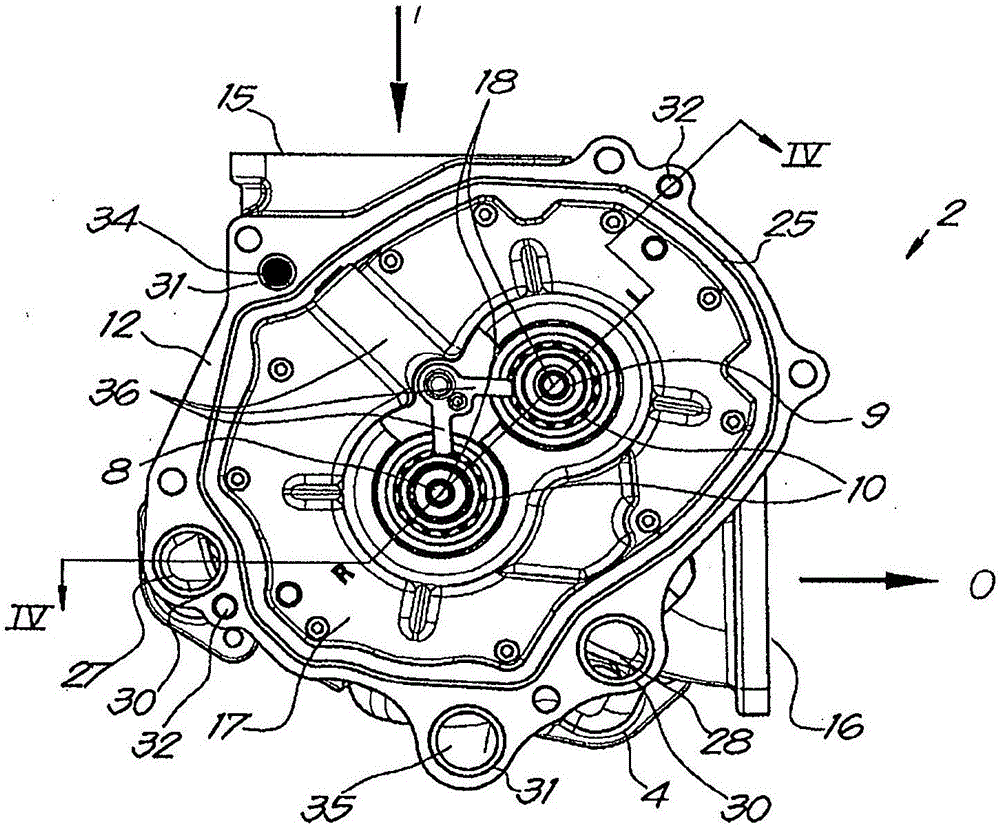

[0046] Such as Figure 4 As shown, the compressor element 2 comprises a housing 4 with two rotor chambers 5 in which screw rotors 6 and 7 (male 6 and female 7 respectively) pass through their respective shafts 8 and 9 Installed on the bearing 10.

[0047] The rotor chamber 5 is sealed by a shaft seal 11 which is attached around the shafts 8 and 9 .

[0048] The housing 4 of the compressor element 2 is provided with a mounting surface 12 via which the compressor element 2 is mounted by bolts or similar not shown means to a corresponding mounting surface 13 of the housing 14 of the gearbox 3 .

[0049] These mounting surfaces 12 and 13 shown in the example are completely flat and extend in a plane transverse to the axial direction of the rotors 6 and 7 .

[0050] The housing 4 of the compressor element is provided with an inlet 15 and an outlet 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com