Automatic top-stop fixing equipment of short zipper and control method thereof

A technology for making top stops and zippers, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of inability to produce short chains, etc., and achieve the effect of simple structure, easy operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

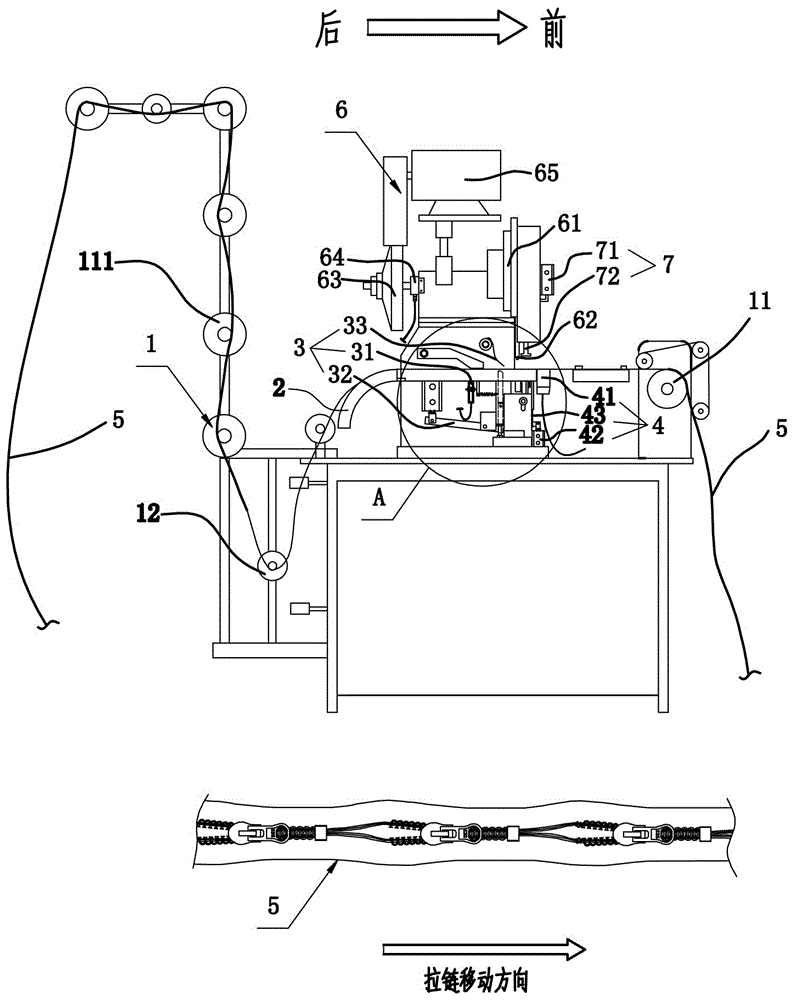

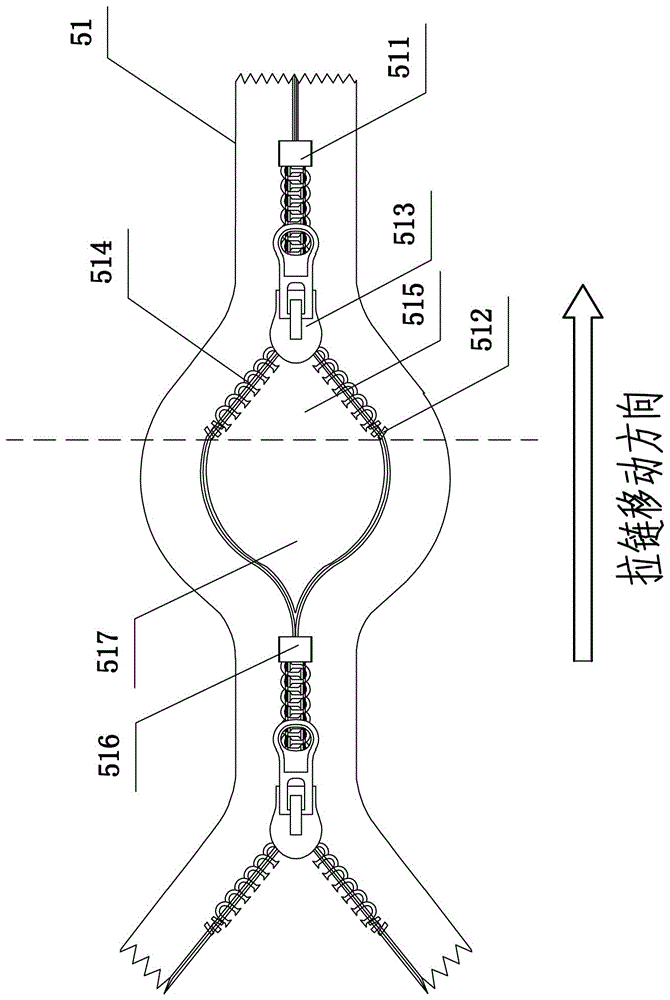

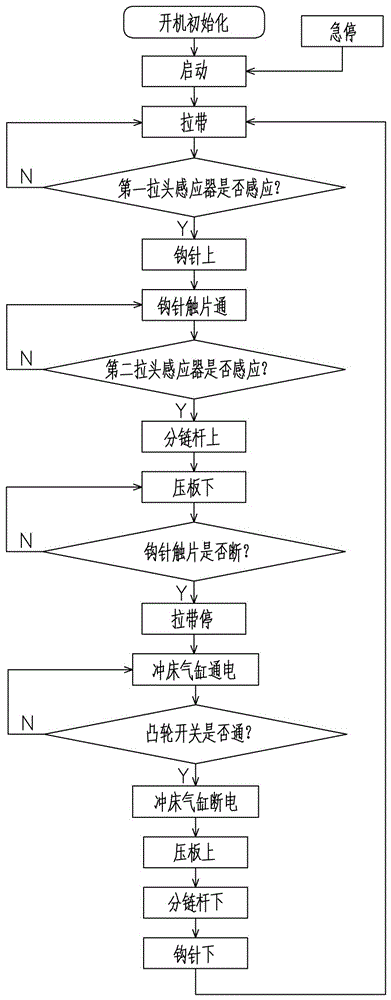

[0034] refer to figure 1 , figure 2 , image 3 with Figure 4 . An automatic top stop device for a short zipper, comprising a pull belt device 1, a chain guide plate 2, a limit device 3 and a chain splitting device 4 which are all connected to the pull belt device 1 circuit, the pull belt device 1 drags the zipper 5 in the guide Move on the chain plate 2; the slide fastener 5 includes a plurality of short chains 51 connected end to end; the top of the chain guide plate 2 is equipped with a stamping device 6 for marking the top stop of the short chains 51, and the stamping device 6 is connected with the pull belt device 1 signal. The short chain 51 moves forward from the bottom stop 511, the top stop 512 faces backward and moves forward from the limit device 3 to the chain splitting device 4; the chain between the slider 513 and the top stop 512 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com