Crushing device

A technology of material bucket and hammer, which is applied in the field of smashing devices, can solve the problems of slow speed, time-consuming and labor-intensive, and unsatisfactory rice cake products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

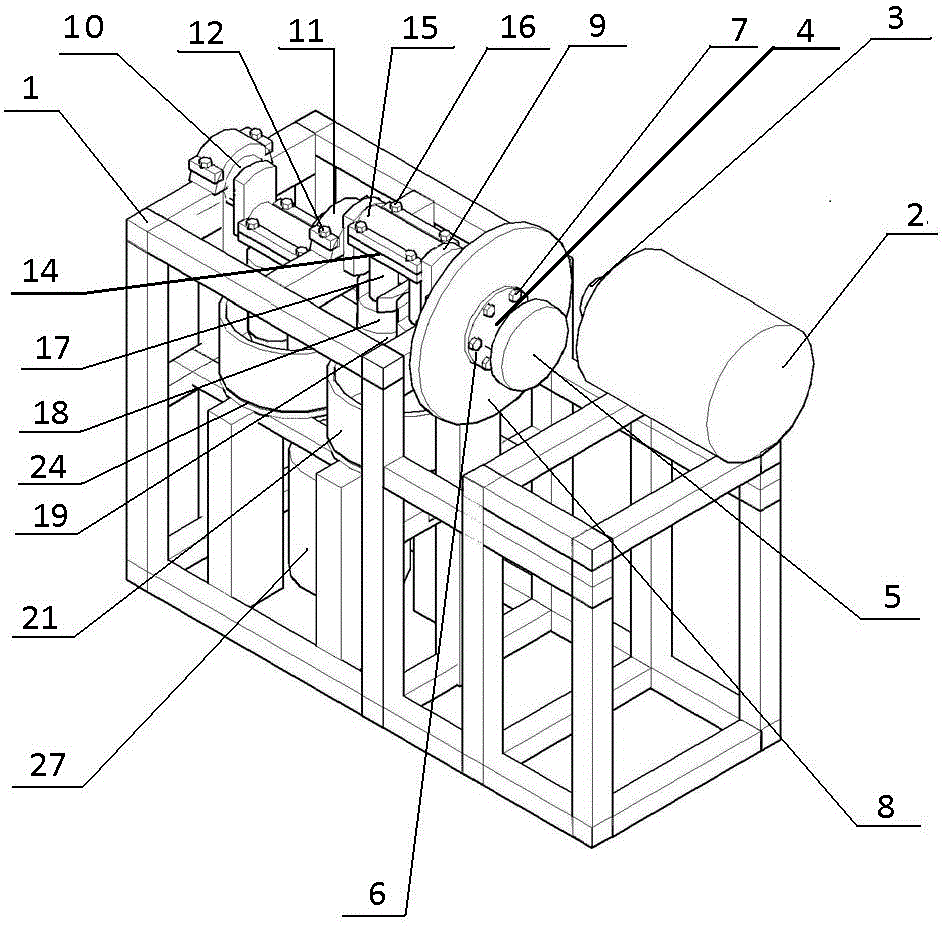

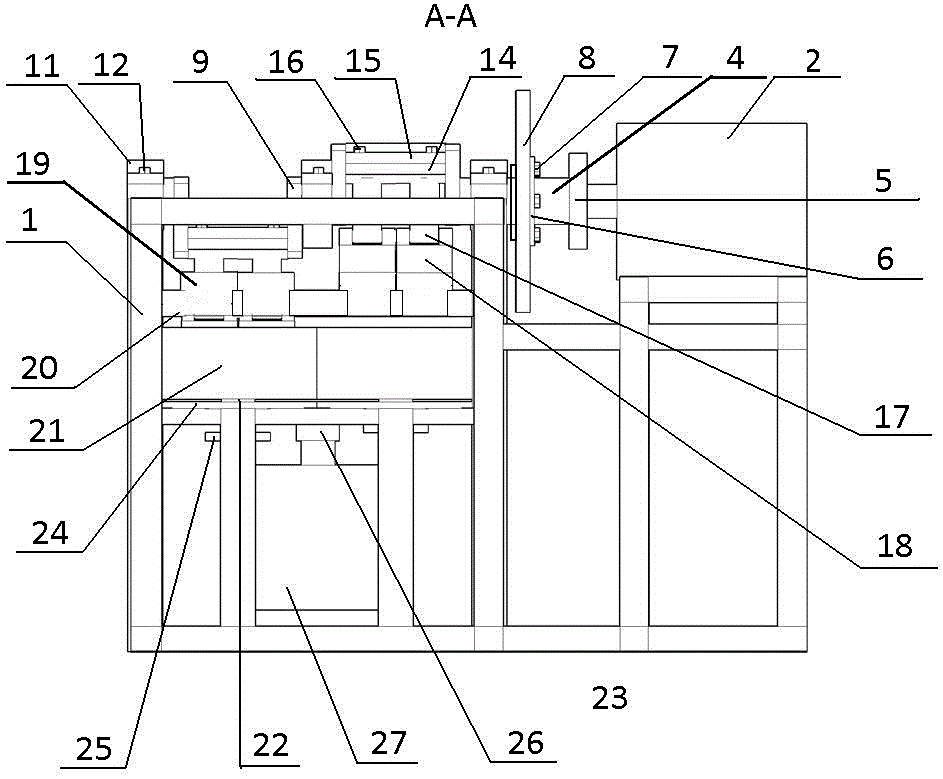

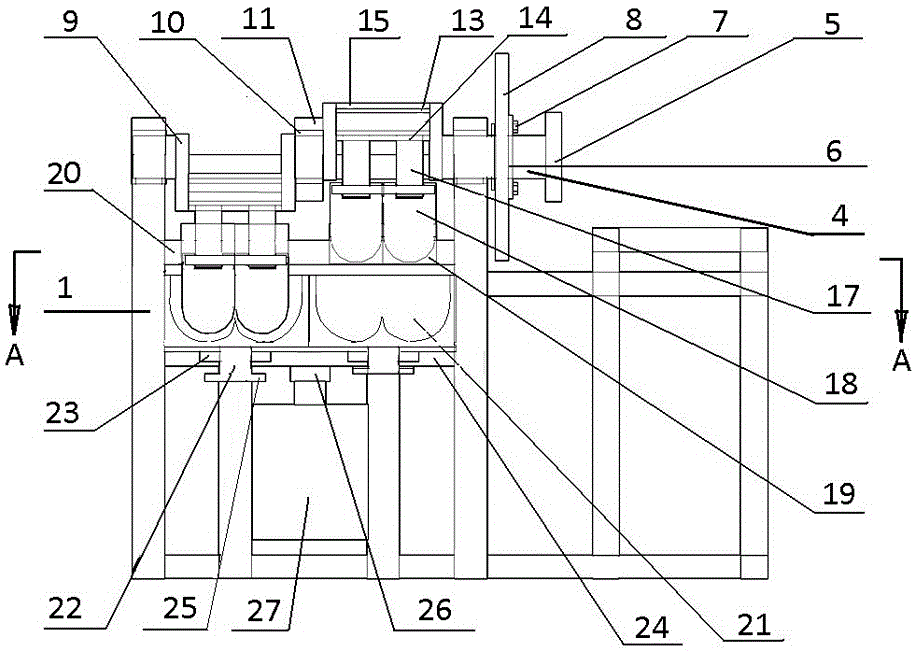

[0025] The following is attached Figure 1 to Figure 8 And preferred embodiment, to the specific implementation, structure, feature and effect of the pounding device that proposes according to the present invention, describe in detail as follows.

[0026] see Figure 1 to Figure 4 , the smashing device of the present invention includes a hammer head 18, a scraper sleeve 19, and a barrel 21, and is characterized in that: the hammer head 18 has a scraper sleeve 19 outside, and the scraper sleeve 19 is installed on the scraper sleeve seat 20, and the scraper sleeve seat 20 is connected to Frame 1, hammerhead 18 bottoms have bucket 21, bucket 21 lower center is bucket shaft 22, bucket bearing 23 is arranged above bucket shaft 22, bucket bearing 23 has base plate 24 outside, base plate 24 below is frame 1, There is a bucket pulley 25 below the bucket shaft 22, and a motor pulley B26 is arranged on the right side of the bucket pulley 25. The motor pulley B26 is fixed on the motor B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com