Leaf mashing apparatus in chloroplast experiment

A technology of chloroplasts and leaves, which is applied in the field of experimental equipment, can solve the problems of uneven mashing of leaves, troublesome operation, laborious and laborious mashing of leaves by hand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

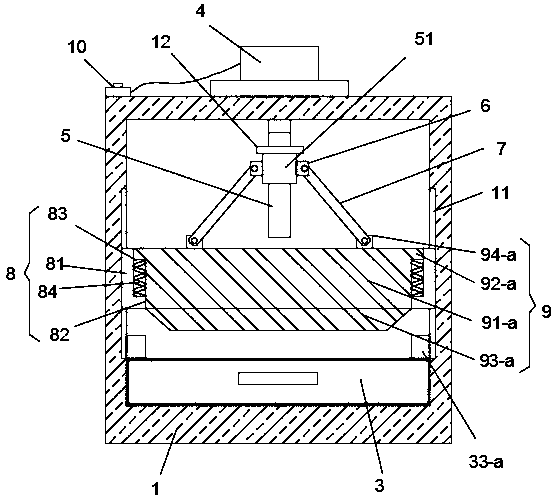

[0022] see figure 1 , figure 2 and Figure 4 , the present invention provides embodiment one: a leaf mashing device in a chloroplast experiment, comprising a box body 1, the lower end of the front surface of the box body 1 is horizontally provided with a first rectangular through hole 2, and the lower edge of the first rectangular through hole 2 Located on the same level as the bottom surface of the box body 1, the blade placement assembly 3 is plugged into the inside of the first rectangular through hole 2, and the upper middle part of the box body 1 is fixedly equipped with a stepper motor 4, and the output shaft of the stepper motor 4 runs through the box body The upper wall of 1 is fixedly equipped with a stud 5, the stud 5 is a fully threaded stud, the outer side of the stud 5 is screwed with a nut 51, the left and right sides of the nut 51 are fixedly equipped with the first ear plate 6, and the two second lugs are fixed. The rear surface of an ear plate 6 is hinged w...

Embodiment 2

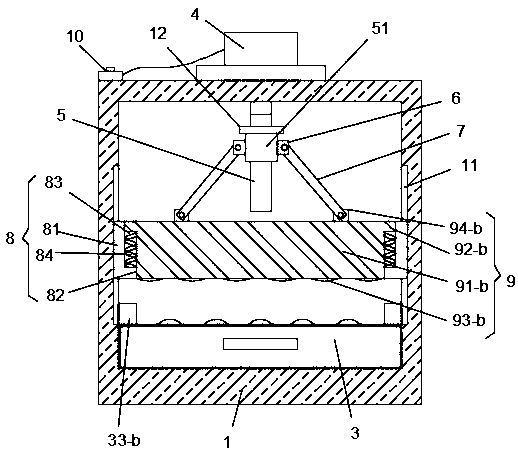

[0034] see figure 1 , image 3 and Figure 5 , the present invention provides Embodiment 2: a leaf mashing device in a chloroplast experiment, comprising a box body 1, the lower end of the front surface of the box body 1 is horizontally provided with a first rectangular through hole 2, and the lower edge of the first rectangular through hole 2 Located on the same level as the bottom surface of the box body 1, the blade placement assembly 3 is plugged into the inside of the first rectangular through hole 2, and the upper middle part of the box body 1 is fixedly equipped with a stepper motor 4, and the output shaft of the stepper motor 4 runs through the box body The upper wall of 1 is fixedly equipped with a stud 5, the stud 5 is a fully threaded stud, the outer side of the stud 5 is screwed with a nut 51, the left and right sides of the nut 51 are fixedly equipped with the first ear plate 6, and the two second lugs are fixed. The rear surface of an ear plate 6 is hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com