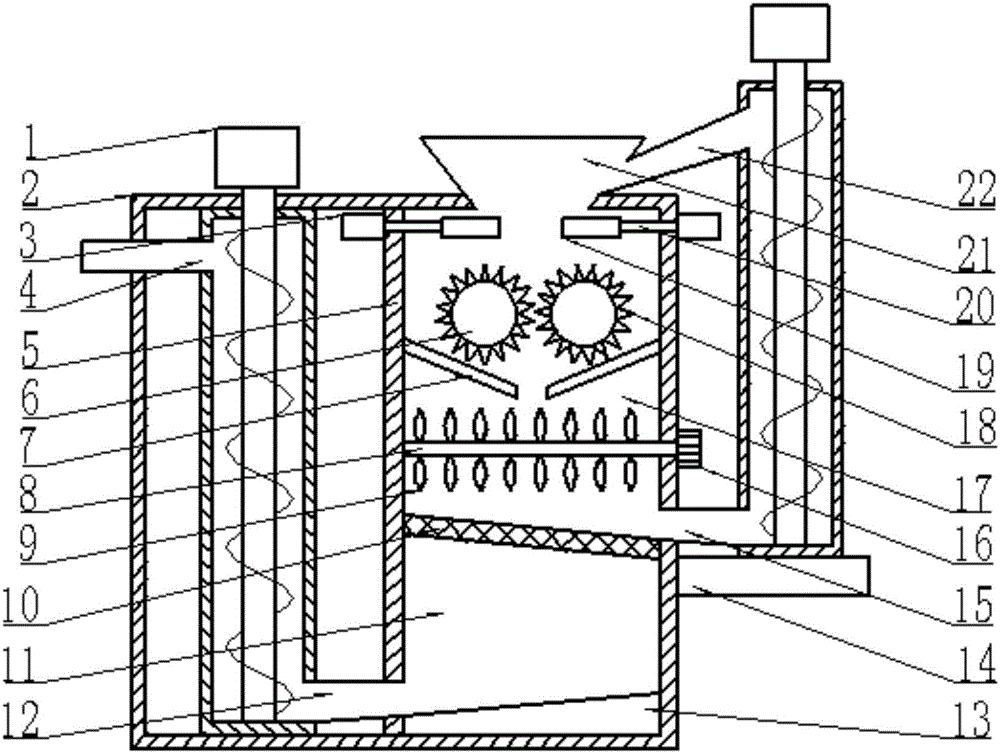

Material smashing device with material elevating function

A technology of pulverizing device and feeding device, which is applied in grain processing and other directions, can solve the problems of poor pulverizing effect, excessive blockage of cutting materials, and equipment that cannot meet the lifting requirements, so as to achieve the effect of convenient speed improvement and avoid material residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

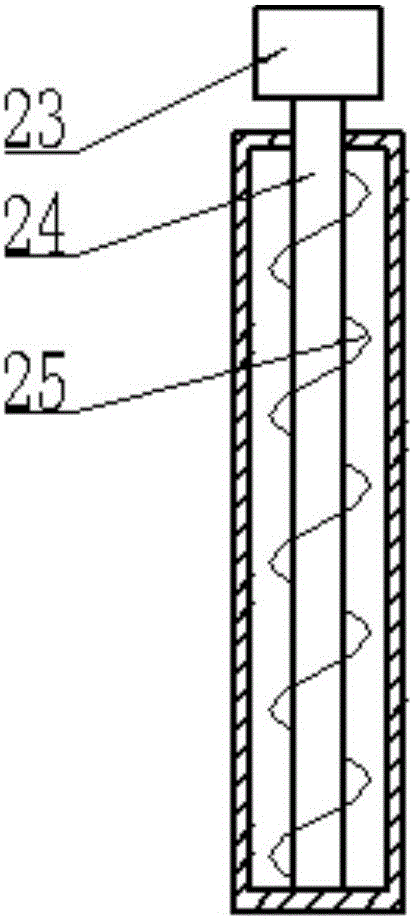

[0019] see Figure 1-2 , the present embodiment provides a material crushing device capable of lifting materials, including a box body 2, a feed hopper 21, a crushing chamber 17, a circulating feeding device, a lower feed bin 11 and a lifting device; the feed hopper 21 is arranged on On the right side of the upper end of the box body 2, a material stopper 19 is provided at the lower end of the feed hopper 21; there are two stopper blocks 19, and the material stopper 19 is connected to the telescopic shaft 18; the telescopic shaft 18 runs through the box body 2 , the telescopic shaft 18 is connected to the cylinder 3; the cylinder 3 is provided with two, which are respectively fixed on the right wall of the casing 2 and the partition 5; the partition 5 is arranged between the lifting device and the crushing chamber 17; the crushing The cavity 17 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com