Anti-explosion automatic dumping device and method and computer readable storage medium

A dumping device, automatic technology, applied in distribution devices, special distribution devices, cleaning methods and utensils, etc., can solve problems such as physical and chemical hazards, work-related injury hazards, health hazards, etc., to avoid residual work materials, improve environmental protection, and improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] The invention provides an explosion-proof automatic dumping device.

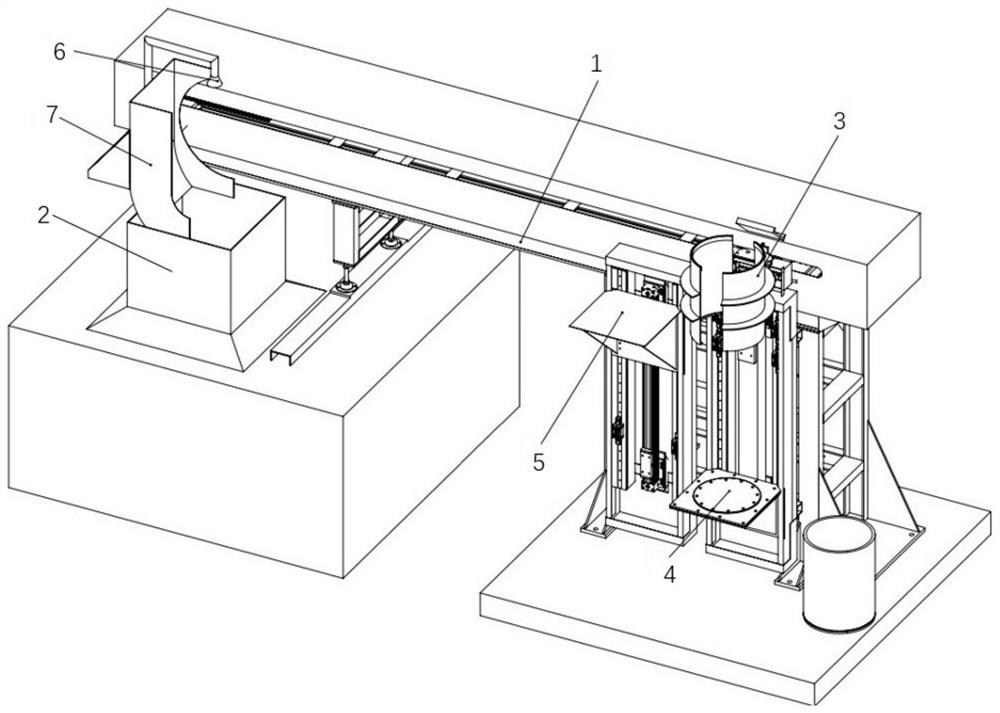

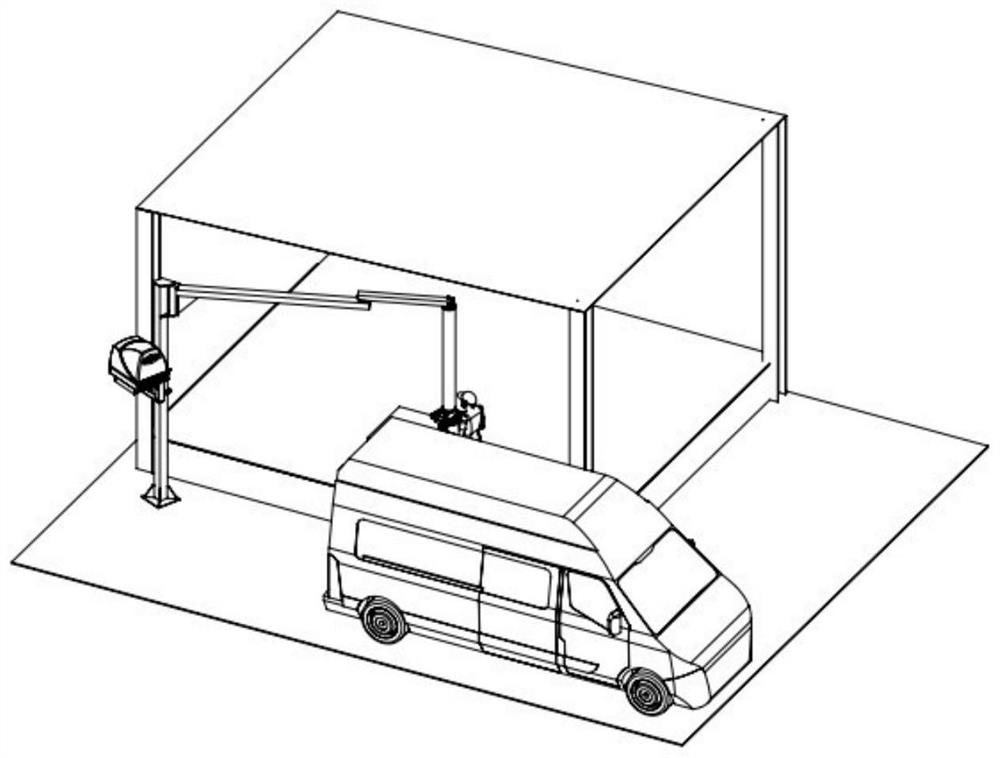

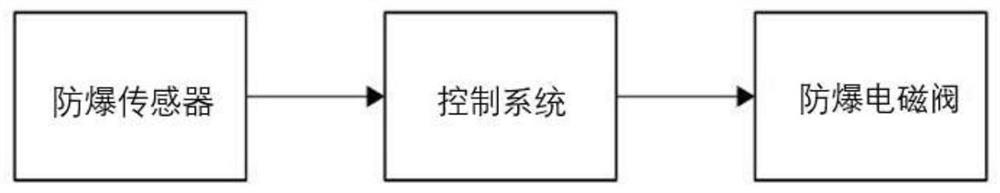

[0055] Such as figure 1 As shown, the explosion-proof automatic dumping device provided according to the present invention includes a main frame 1, a feed port 2, a pneumatic gripper 3, a feeding platform 4, a feeding platform 5, a cleaning device 6, a feeding baffle 7, and an explosion-proof sensor and explosion-proof solenoid valves. Such as image 3 As shown, the explosion-proof automatic dumping device detects the feedback signal through the explosion-proof sensor. Specifically, the feedback signal is the action signal of the equipment, and the PLC control system sends instructions according to the received feedback signal to control the pneumatic gripper 3 and the feeding platform 4 through the explosion-proof solenoid valve. , The unloading platform 5 and the cleaning device 6 move, and the full automation of the equipment is realized by one-key start of the explosion-proof button and the foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com