Patents

Literature

32results about How to "Easy to control the feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

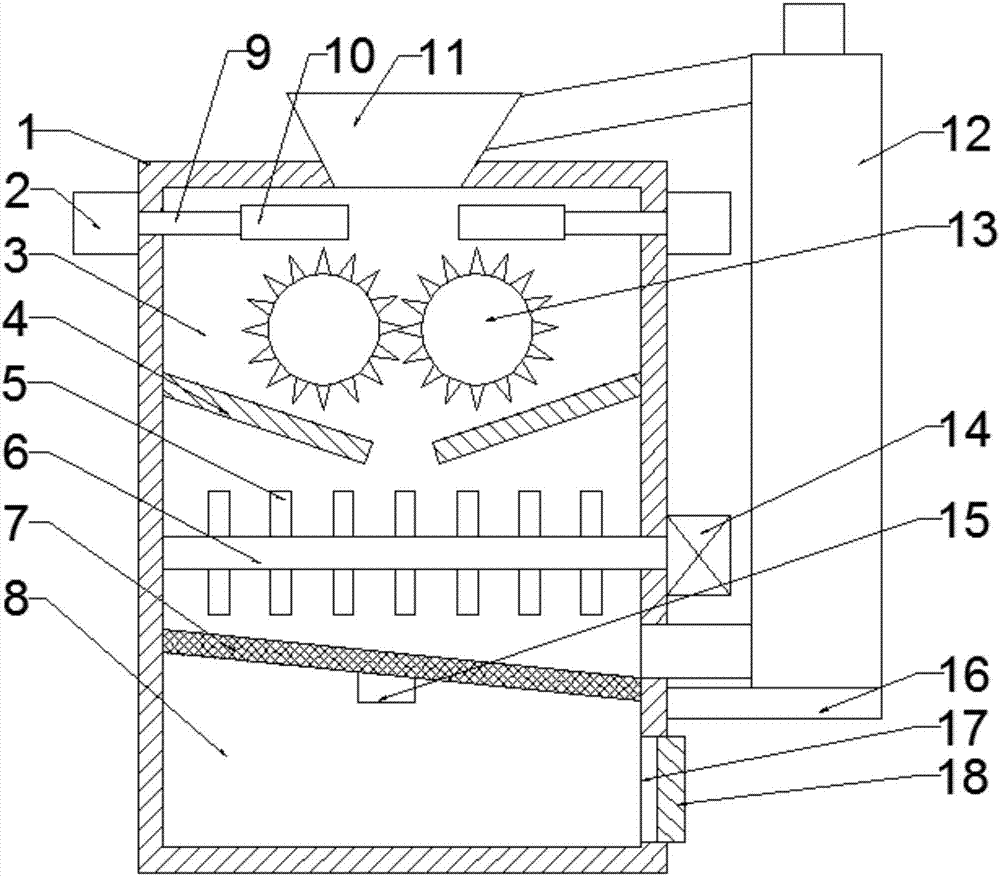

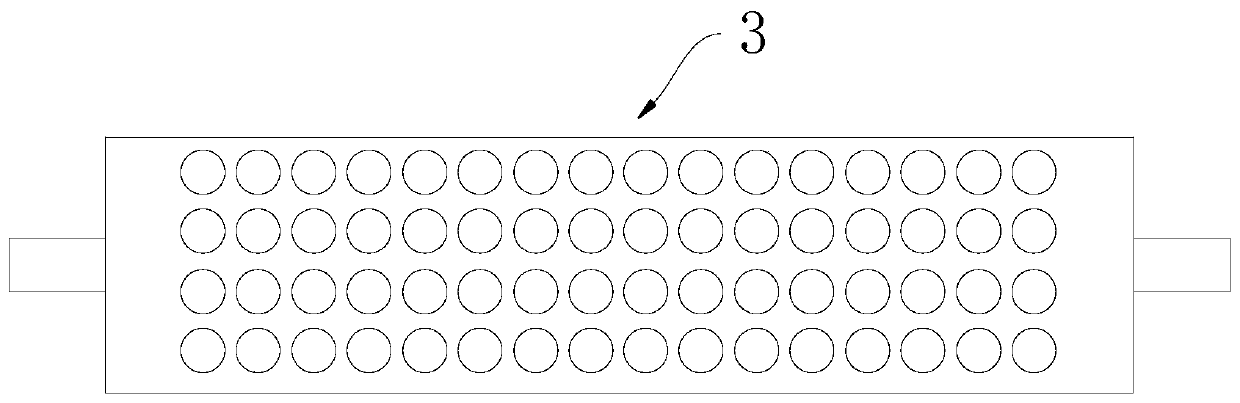

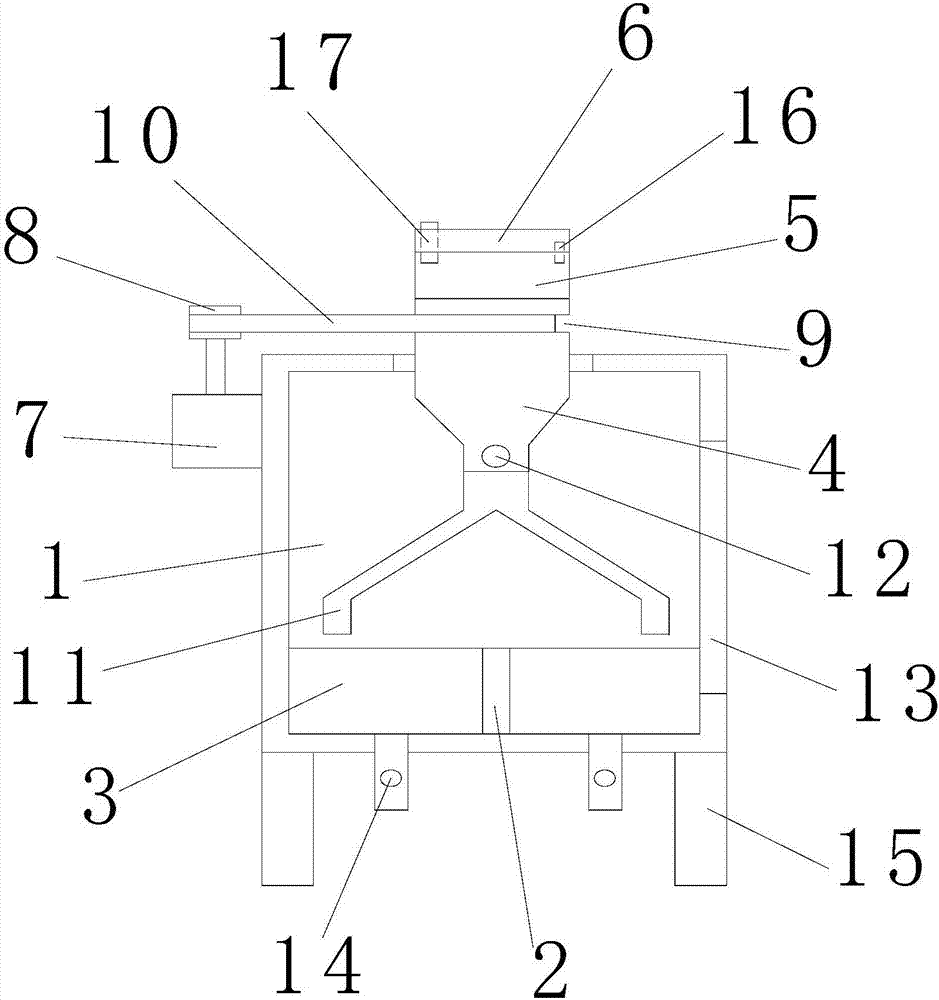

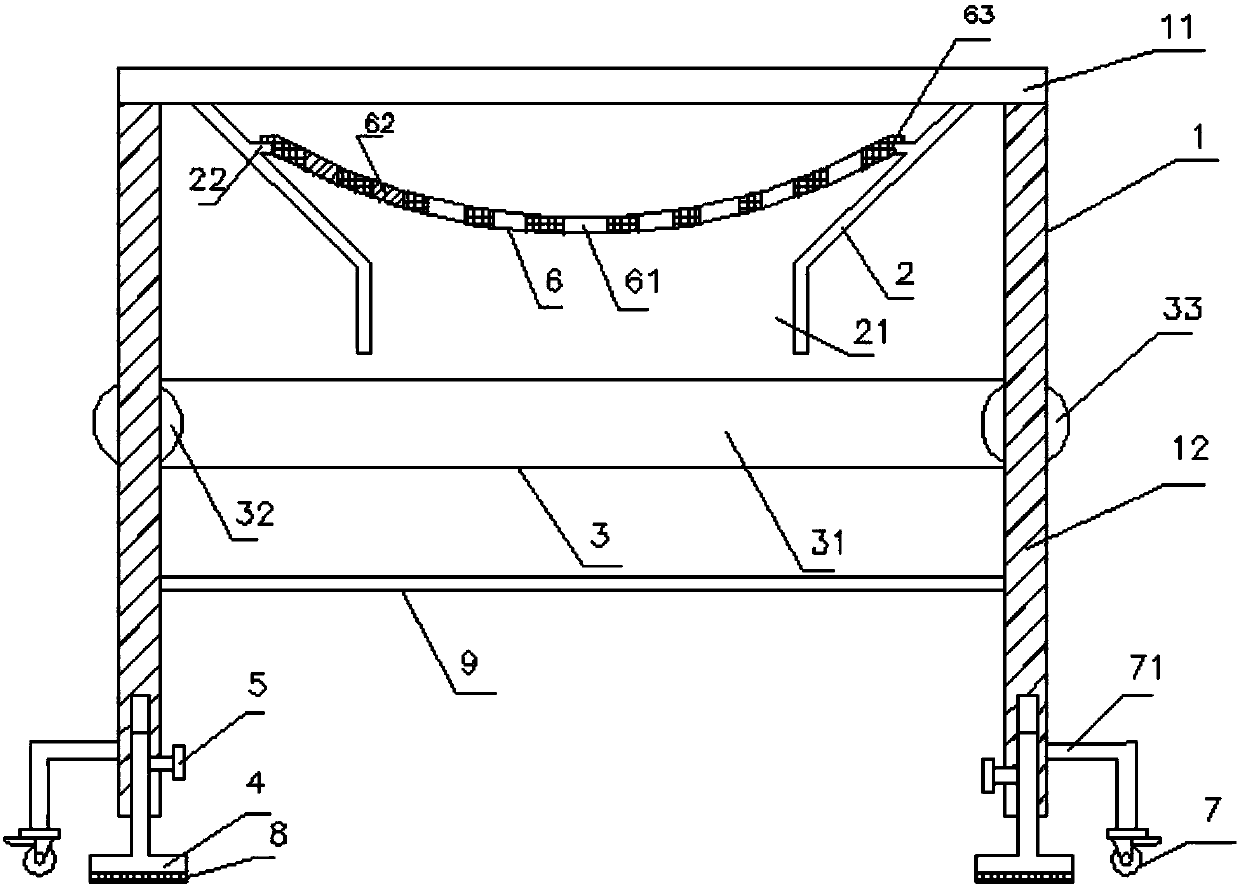

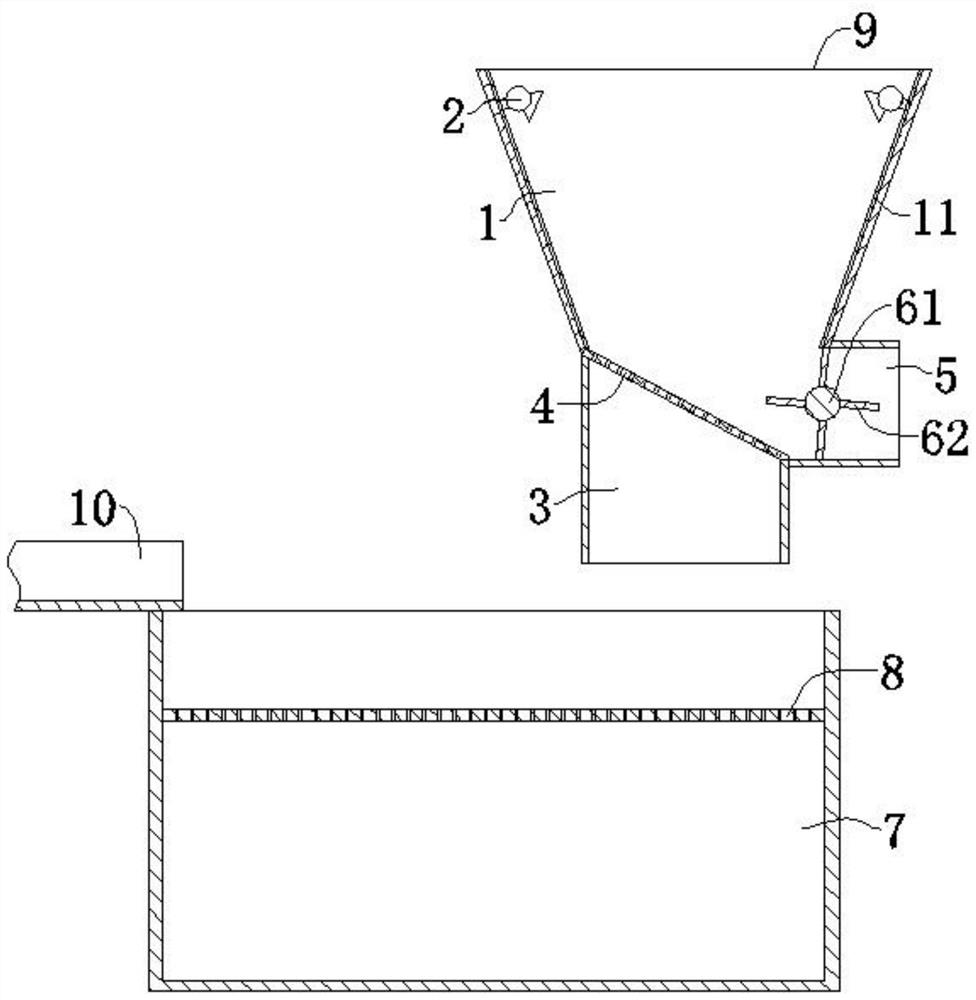

River sand classified screening device for building construction

The invention discloses a river sand classification and screening device for building construction, which comprises a sand box, a feeding box, a screening box, a supporting sliding sleeve, a first gear, a second gear, a primary sieve plate, a secondary sieve plate, a No. The connecting rod and the No. 2 connecting rod, the inside of the sandbox is equipped with a crushing device, and the inner cavity of the feeding box is equipped with a screw feeding device. A drop pipe is connected, and the upper inner cavity of the screening box and the right inner cavity of the feeding box are connected through the second dropping tube. The inside of the screening box is respectively horizontally slidingly provided with a first-level sieve plate and a second-level sieve plate. The transmission connection between the first gear and the first-stage sieve plate is through the No. 1 connecting rod, and the transmission connection between the second gear and the second-stage sieve plate through the No. 2 connecting rod. device. The invention has the advantages of simple structure, convenient use, long service life, good screening effect on river sand, saving manpower and material resources, and improving work efficiency.

Owner:段华勇

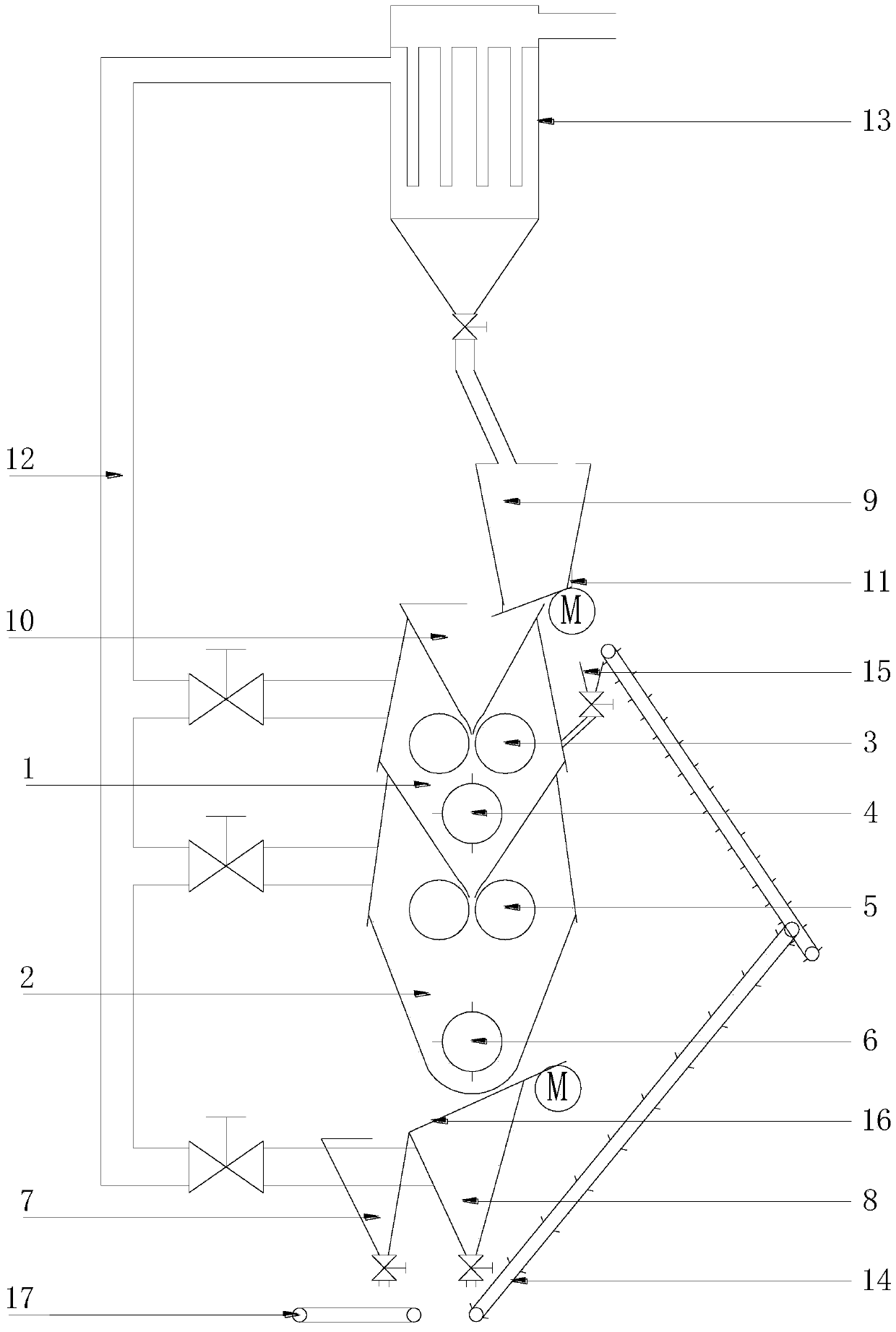

Environment-friendly straw recovery treatment device

The invention discloses an environment-friendly straw recovery treatment device and belongs to the field of environment-friendly equipment. The environment-friendly straw recovery treatment device comprises a shell, an air cylinder, a smashing cavity, discharging plates, smashing blades, a rotating shaft, a screen, a discharging cavity, a telescoping shaft, material stop blocks, a feeding hopper, a material lifting device, a smashing roller, a rotating motor, a vibration exciter, a fixing plate, a discharging opening and a discharging baffle. The feeding hopper is arranged in the center of the upper end of the shell. The material stop blocks are arranged at the lower end of the feeding hopper. The number of the material stop blocks is two. The material stop blocks are connected to the telescoping shaft. The smashing cavity and the discharging cavity are formed in the shell. The smashing cavity is located on the upper side of the discharging cavity. The discharging plates are arranged on the lower side of the smashing roller obliquely. The number of the discharging plates is two. A discharging channel is formed between the two discharging plates. The environment-friendly straw recovery treatment device is reasonable in structure and convenient to use, the discharging speed can be controlled, thorough smashing can be achieved by means of the smashing device, circular smashing can be achieved, and straw smashing quality is improved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

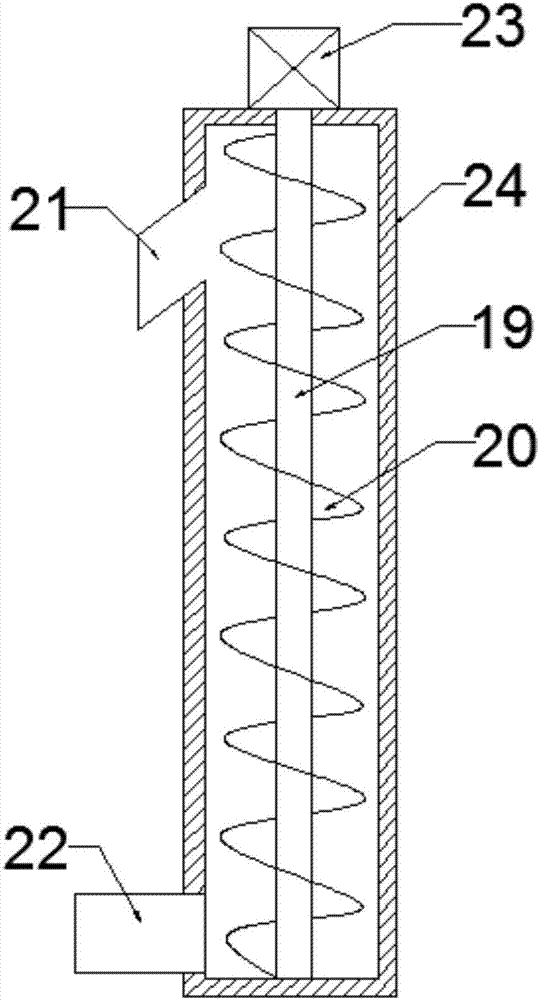

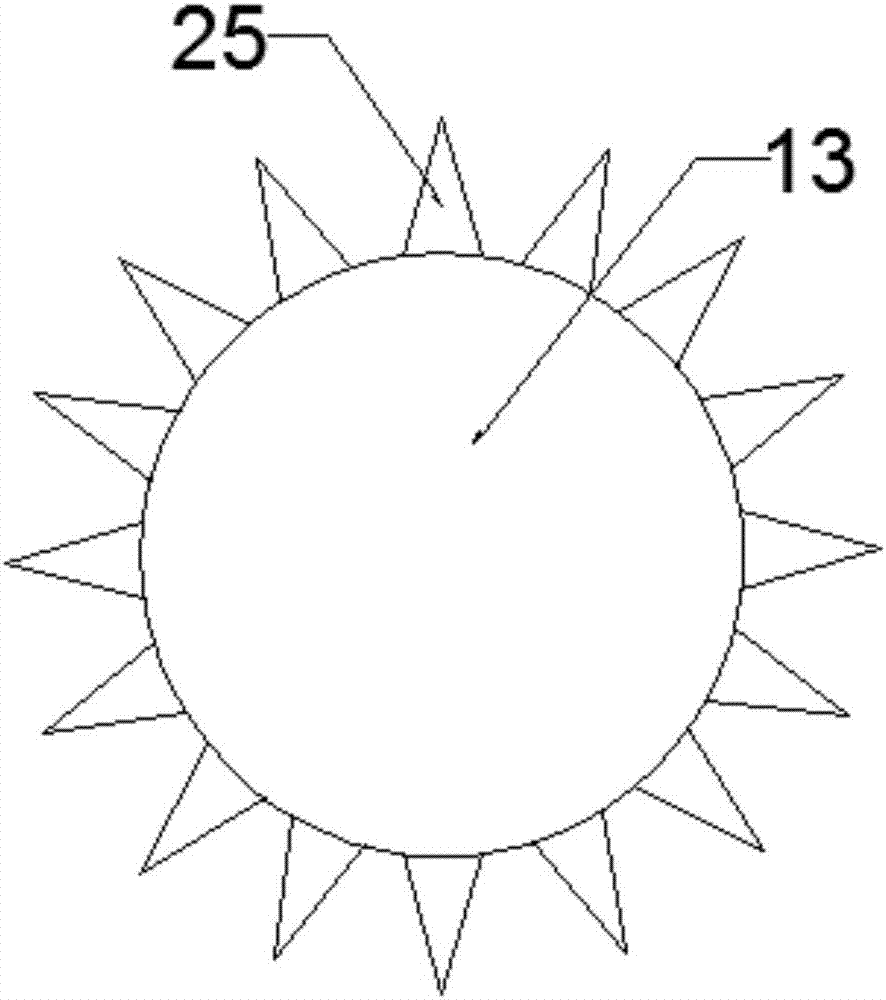

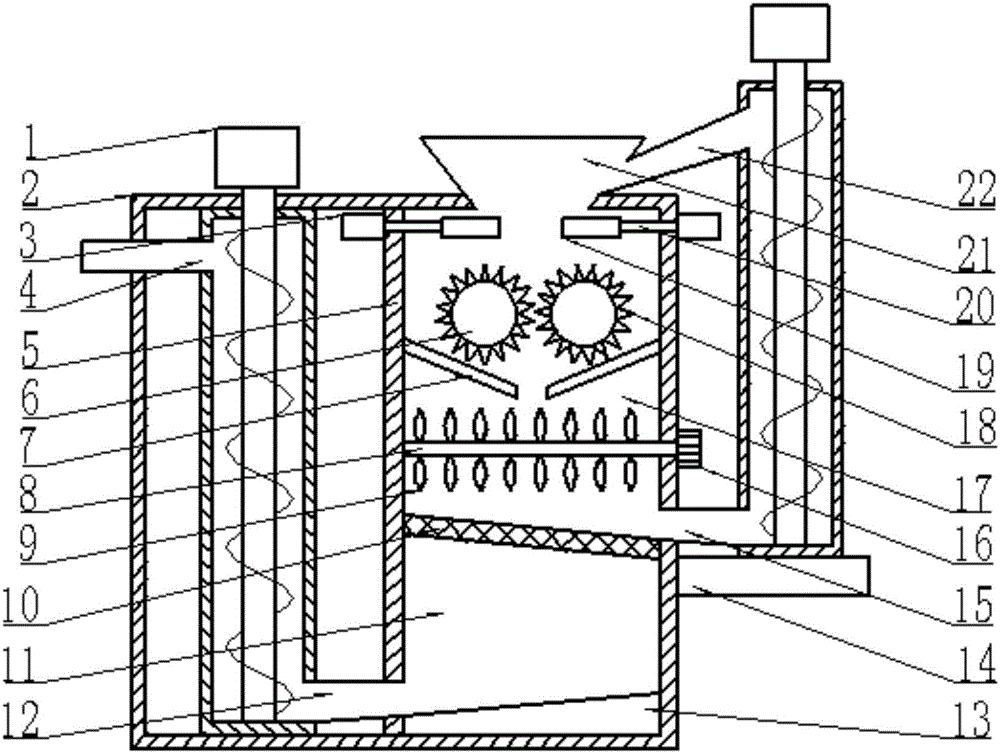

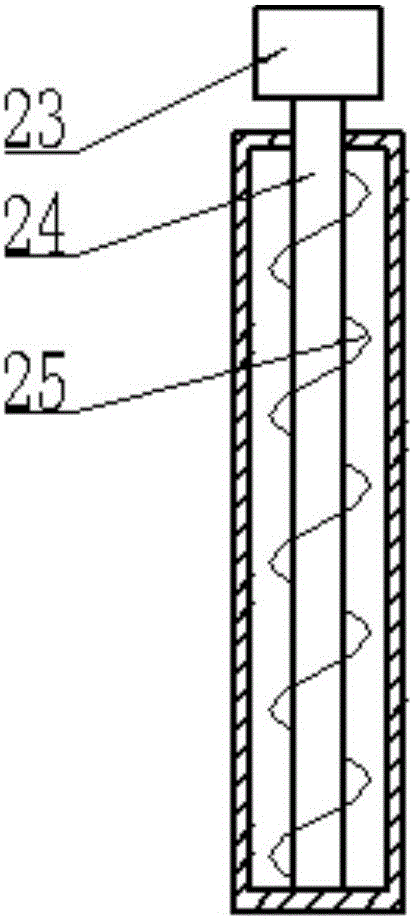

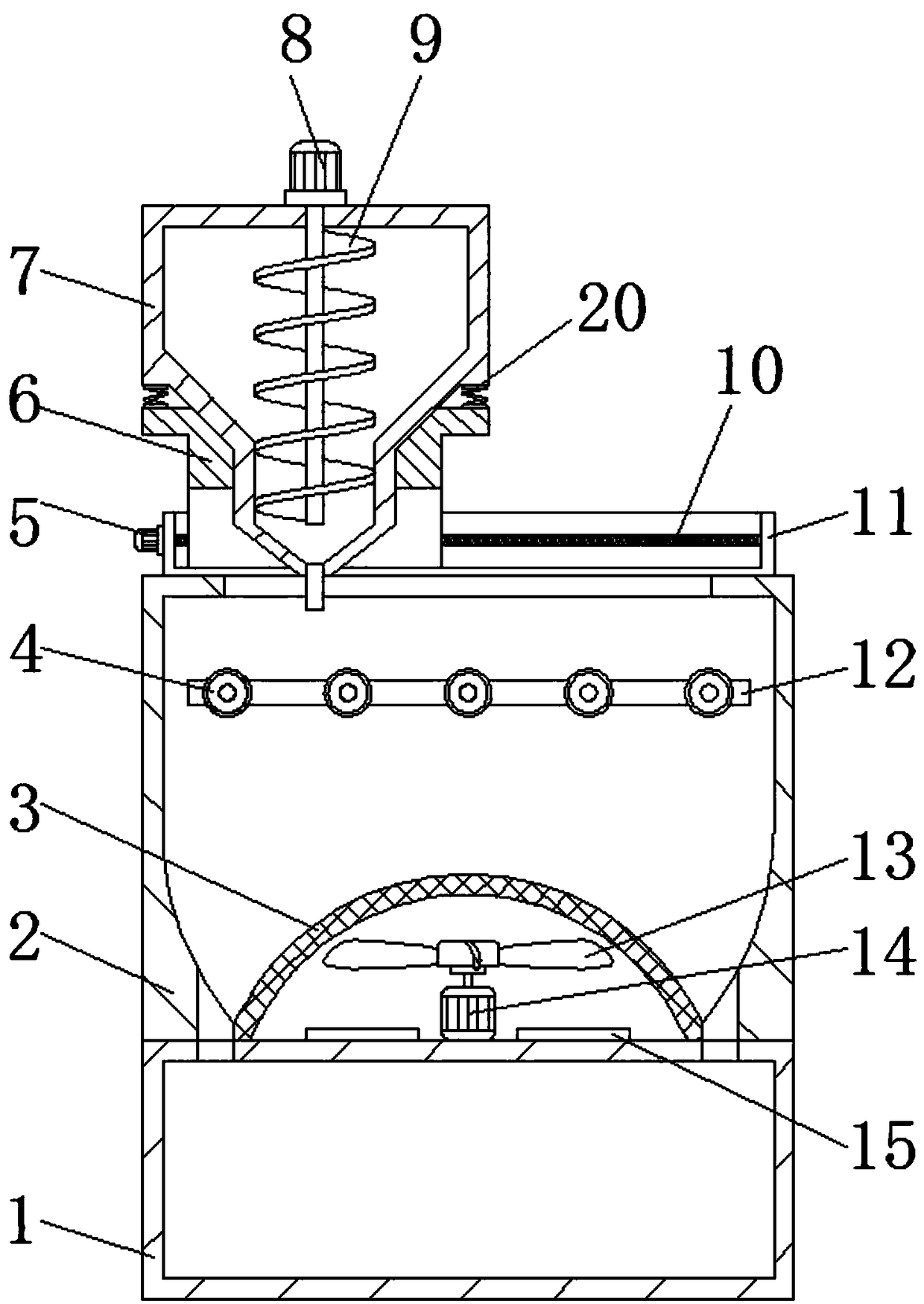

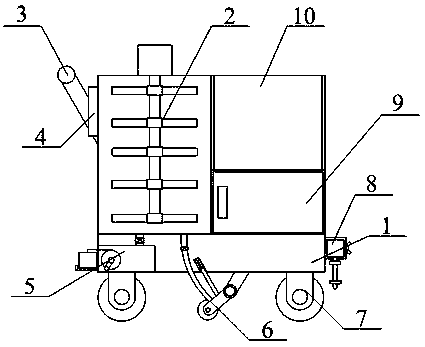

Material smashing device with material elevating function

InactiveCN106732924AIncrease convenience speedAvoid material residueGrain treatmentsMechanical engineeringEngineering

The invention provides a material smashing device with a material elevating function. The material smashing device comprises a box body, a feeding hopper, a smashing cavity, a circulating feeding device, a discharging bin and an elevating device. The feeding hopper is arranged on the right side of the upper end of the box body. Material check blocks are arranged at the lower end of the feeding hopper. Smashing rollers and a rotary shaft are arranged in the smashing cavity. The rotary shaft penetrates the box body. A rotary motor is arranged at the right end of the rotary shaft. Smashing blades are arranged on the rotary shaft. The rotary motor is fixed to the right end of the box body. The circulating feeding device comprises a feeding motor, a second discharging pipe and a second feeding pipe. The discharging bin is arranged at the lower end of the smashing cavity. A screen and an inclined bottom plate are arranged in the feeding bin. The elevating device comprises an elevating motor, a first discharging pipe and a first feeding pipe. The first discharging pipe is arranged on the upper portion of the left end of the elevating device. The first feeding pipe is arranged on the lower portion of the right end of the elevating device. The material smashing device is thorough in smashing effect and capable of achieving circulating smashing, controlling the discharging speed and facilitating material elevating.

Owner:郑州吉音动漫科技有限公司

Harmless treatment method of medical garbage

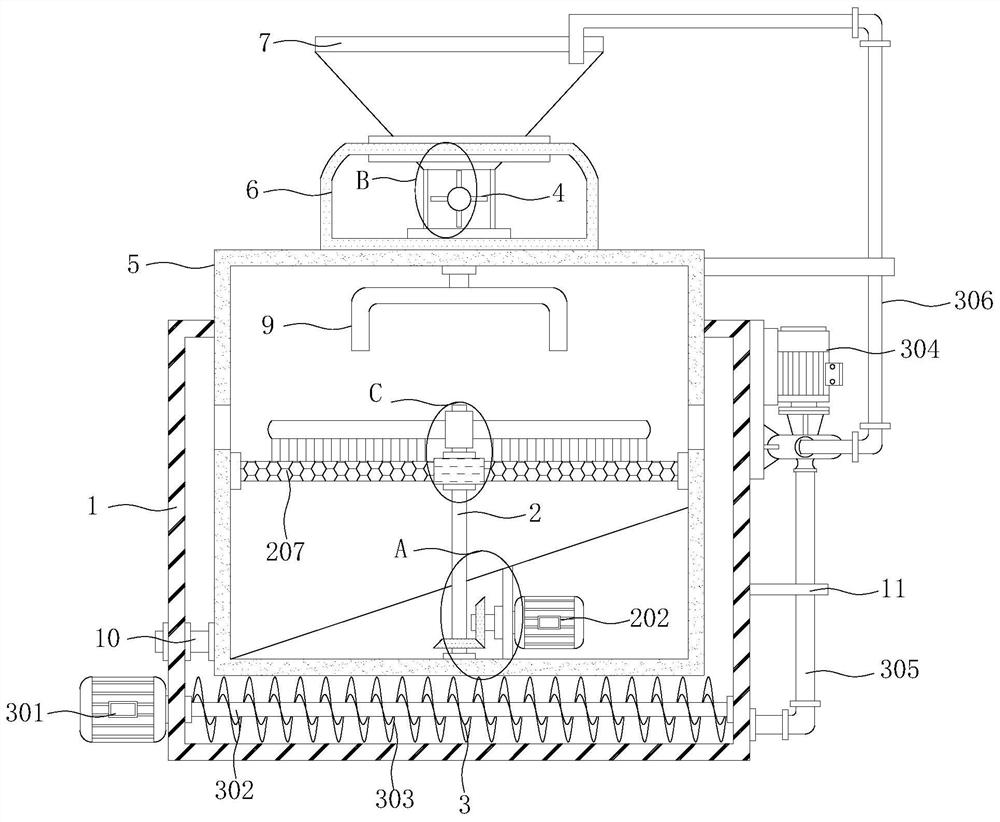

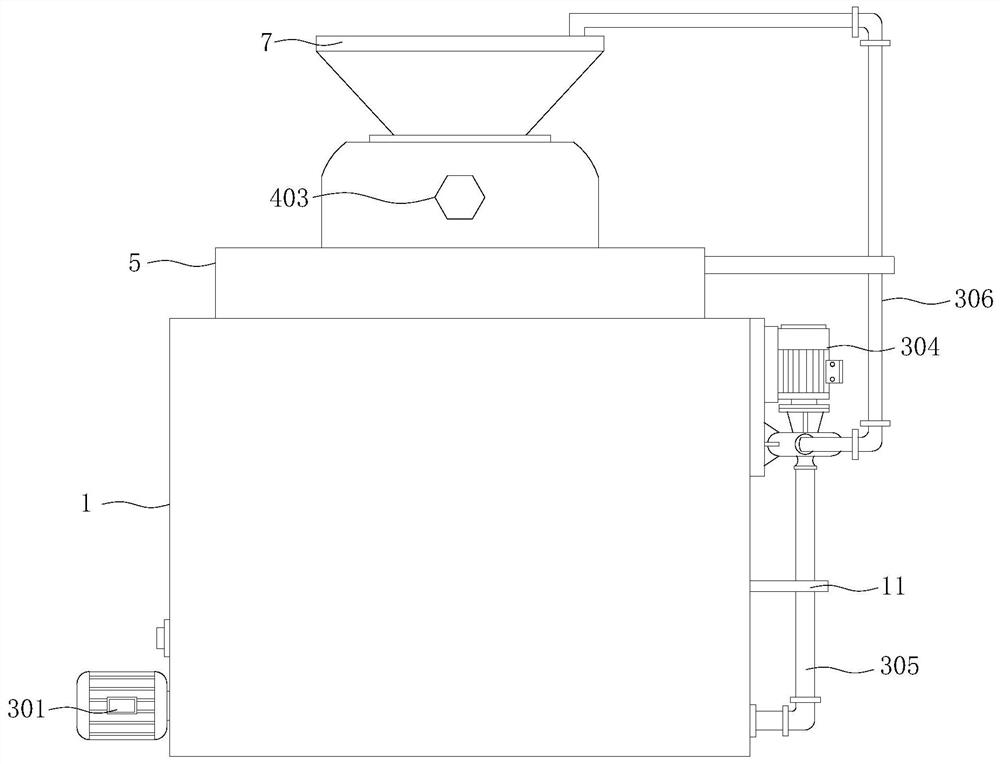

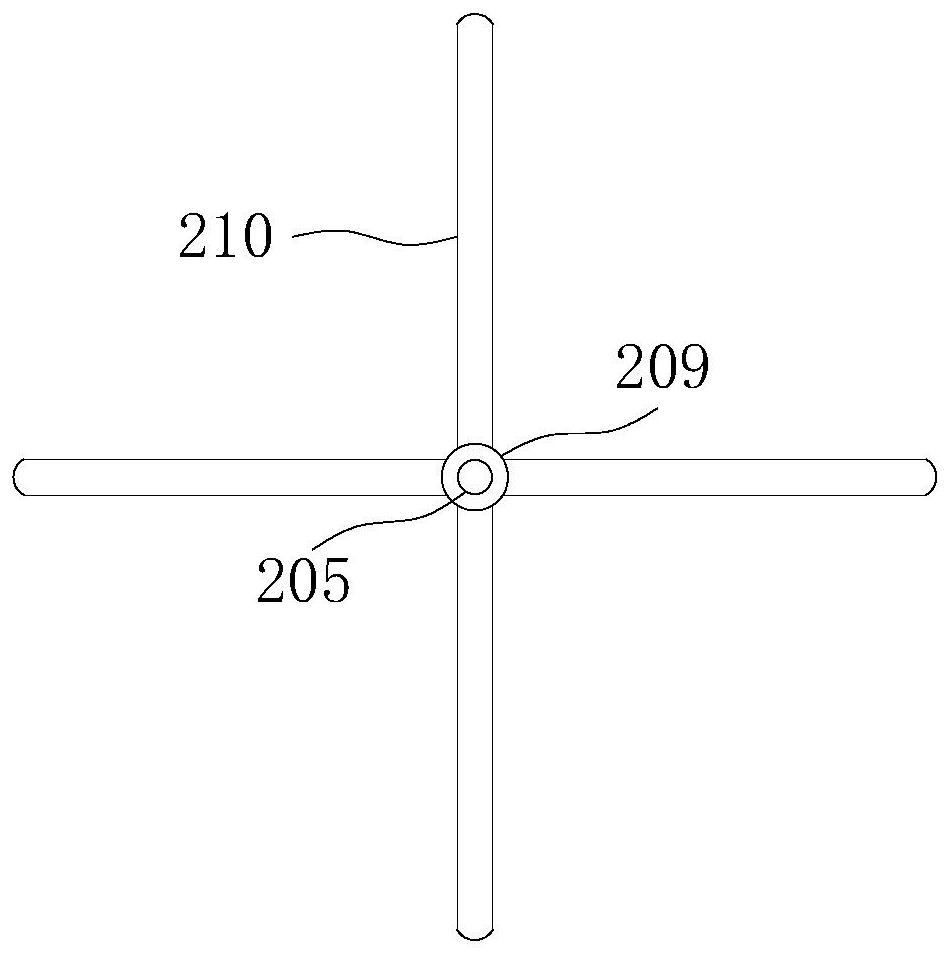

ActiveCN109047270AImprove disinfection efficiencyConvenient sewage treatmentSievingSolid waste disposalEngineeringTextile

The invention relates to the technical field of medical garbage treatment, in particular to a harmless treatment method of medical garbage. The method comprises the following steps that firstly, the medical garbage can be collected by a medical disinfecting garbage can; secondly, large-scale materials and large objects which can be independently recycled in the medical disinfecting garbage can canbe separated to carry out independent colleting and recycling processing, and other materials are centralized processed; thirdly, all the materials subjected to centralized processed are crushed; fourthly, the crushed garbage is sent into a disinfection device, an oxidation sterilizing agent and a conditioner are added, and then a sterilization treatment with heating and pressurization is carriedout in the disinfection device; the sterilized and disinfected residue is discharged from the disinfection device, and sorting processing is carried out; and fifthly, recycle is carried out on wasteplastic, a needle tube and the like which are subjected to crush and magnetic separation, and the residue of cotton, broken cloth, gauze and the like are subjected to incineration disposal through a boiler or landfill treatment. According to the method, the disinfecting efficiency of the medical garbage can be greatly improved.

Owner:刘晶晶

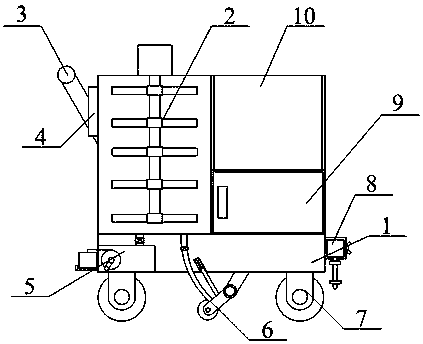

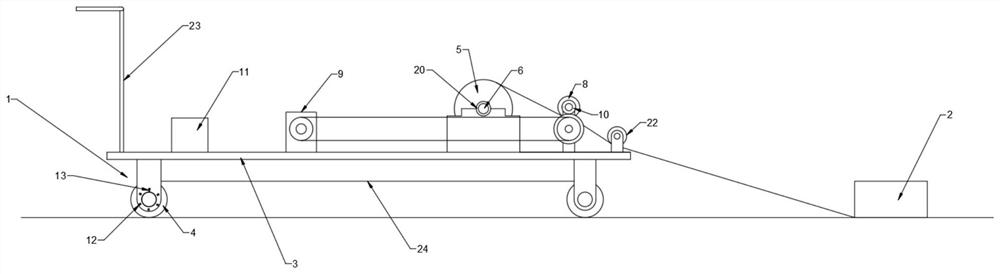

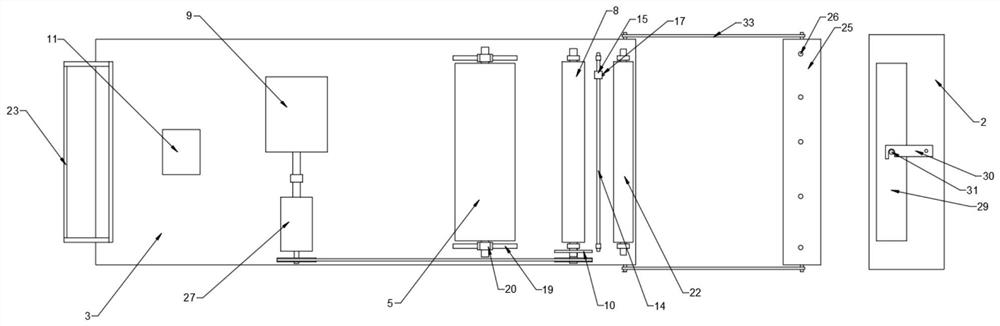

Convenient-to-maintain and efficient road hot-melt ruling machine

ActiveCN107675603AThe liquid material is mixed evenlyImprove buffering effectRoads maintainenceEngineeringMaterial structure

The invention provides a convenient-to-maintain and efficient road hot-melt ruling machine. The convenient-to-maintain and efficient road hot-melt ruling machine comprises a base, a stirring heating material box structure, a pushing handle, an intelligent control device, a ruling rope structure, a ruling wheel structure, a bottom wheel, a positioning guide rod structure, a tool storing box structure and a standby material box; and the stirring heating box material structure is welded to the left side of the upper portion of the base, and the pushing handle is welded to the left side of the upper portion of the stirring heating material box structure. According to the convenient-to-maintain and efficient road hot-melt ruling machine, by arranging a transparent observation window, convenientobservation of the liquid level height in a stirring box is facilitated; by arranging a stirring motor, a stirring shaft and a stirring rod, convenient and full stirring of raw materials in the stirring box is facilitated, so that liquid materials are mixed more evenly; one end of a buffering rod is inserted in a buffering groove, the other end of the buffering rod is in shaft connection to the left side of the upper portion of a guide wheel bracket, improving of the buffering effect when the ruling guide wheel touches the ground is facilitated, and the ruling guide wheel is prevented from being damaged by colliding with the ground; and by arranging scale lines, convenient measuring the distance between high equipment and curbstone is facilitated.

Owner:山东金圭交通设施有限公司

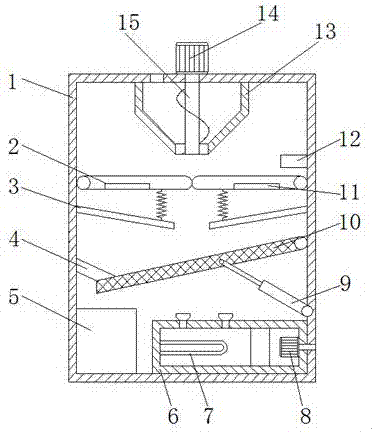

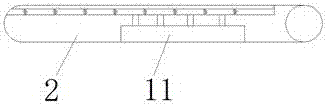

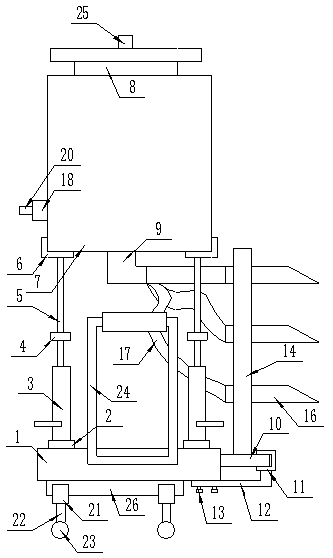

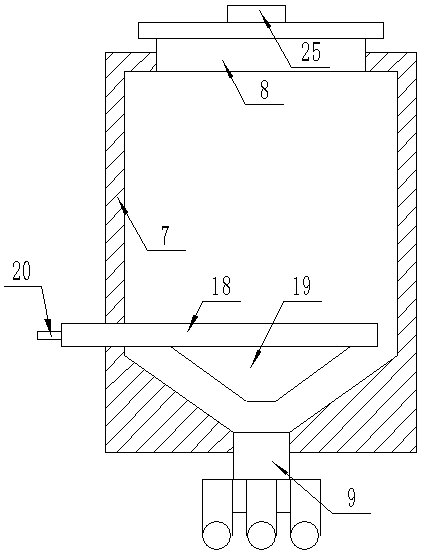

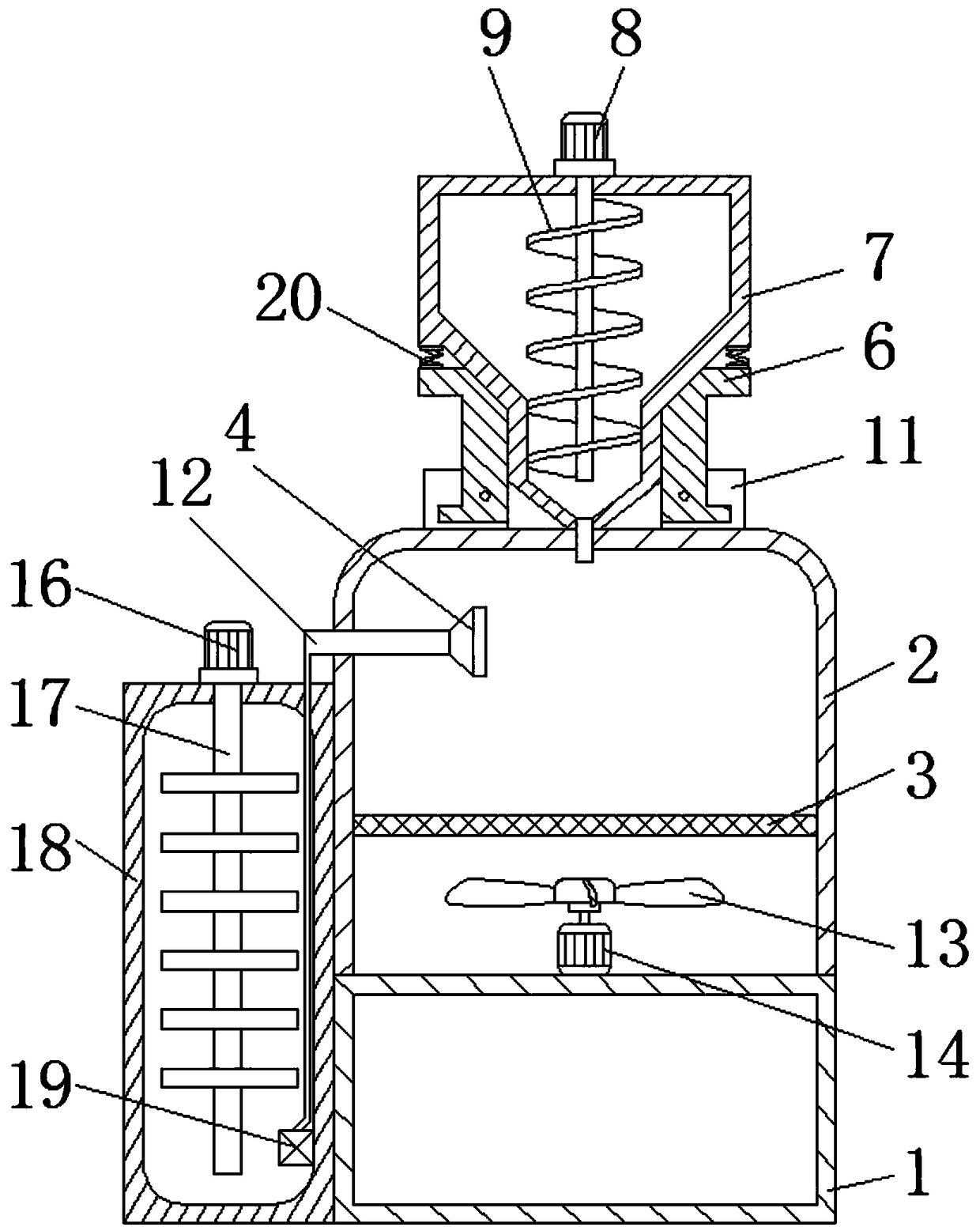

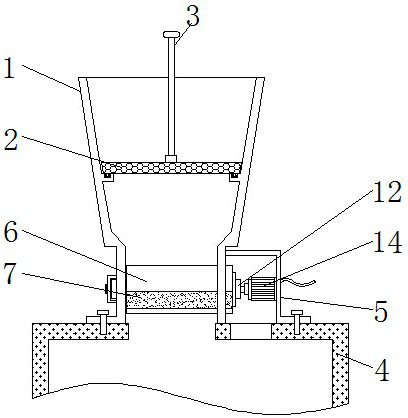

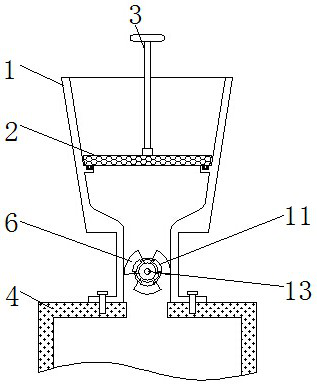

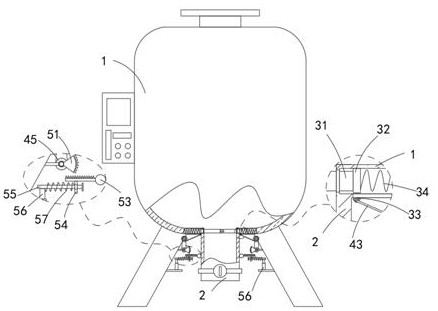

Stirring-free drying device for pharmacy

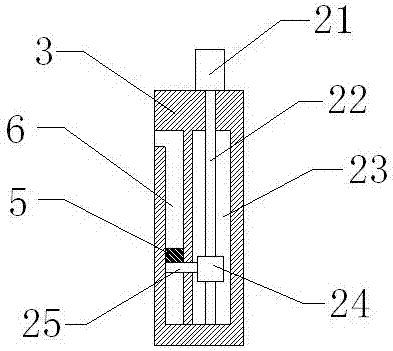

InactiveCN107883691ASimplify the manufacturing processEasy to control the feeding speedDrying gas arrangementsDrying solid materialsCouplingEngineering

The invention discloses a non-stirring drying device for pharmacy, which comprises a casing, the top inner wall of the casing is fixed with a barrel by screws, and the bottom outer wall of the barrel is provided with a discharge port, and the top outer wall of the casing is opened. There is a feeding shaft installation hole, and the inner wall of the feeding shaft installation hole is connected to the feeding shaft through a bearing, the top outer wall of the housing is fixed with a motor through a screw, and the output shaft of the motor is fixed on the outer wall of one end of the feeding shaft through a coupling. The inner wall of one side of the housing is connected with a rotating plate through a hinge, and the inner wall of one side of the housing is fixed with a strut by screws, and the strut is located directly below the rotating plate. The present invention can realize quantitative batch drying, and carry out equal-weight batch batching of raw materials while drying, which provides convenience for the subsequent drug production process, helps to improve the drying rate, and can realize automatic feeding, with a high degree of automation. It is easy to operate and can reduce the labor intensity of the staff.

Owner:蚌埠市宏大制药机械有限公司

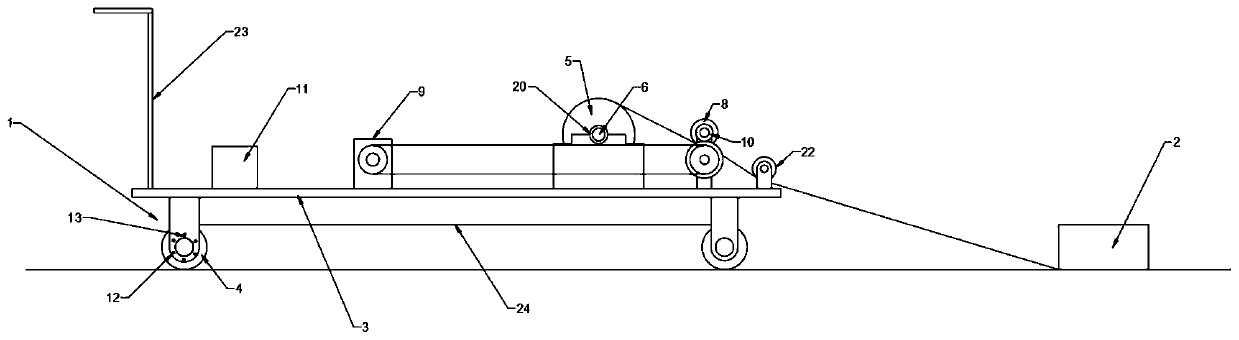

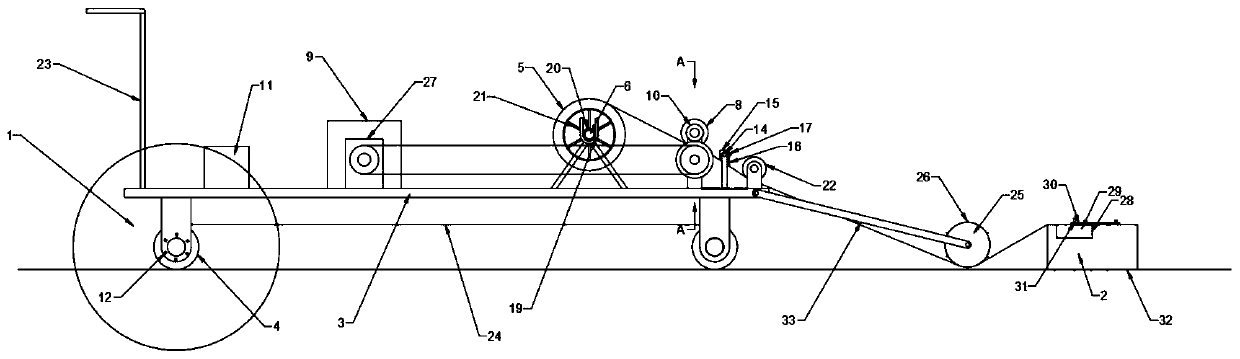

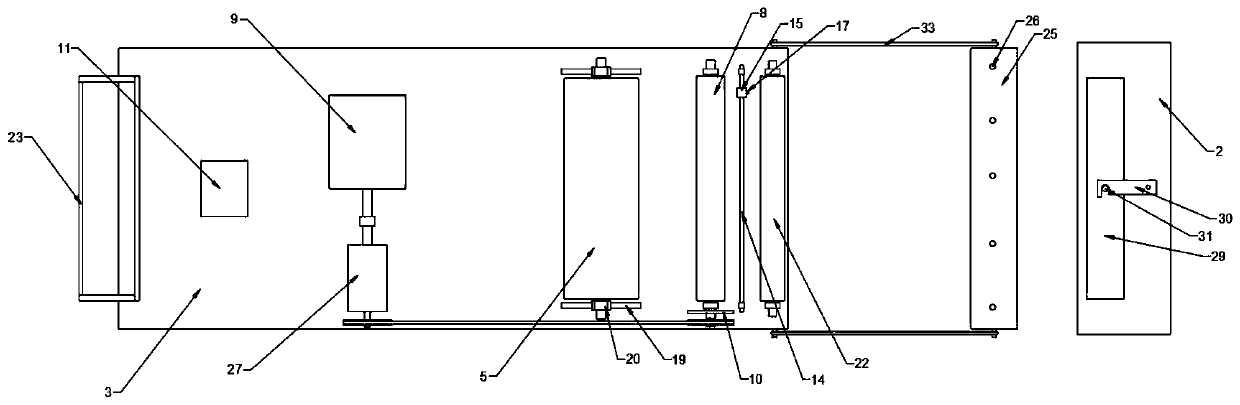

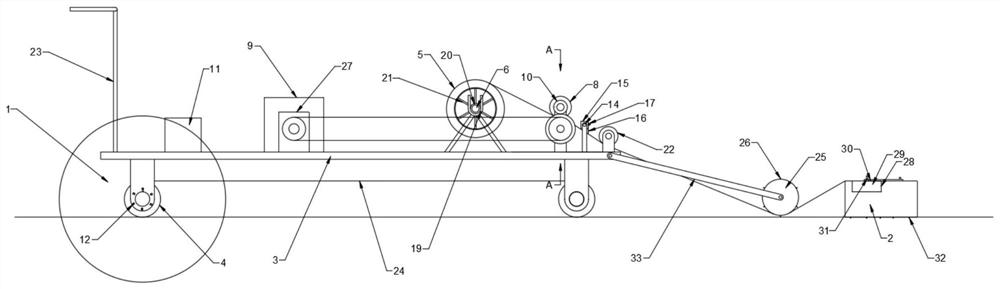

Concrete protective film laying device

ActiveCN111364784AImprove laying efficiencyImprove flatnessRoads maintainenceBuilding material handlingServoEngineering

The invention provides a concrete protective film laying device. The concrete protective film laying device comprises a laying trolley and a fixing pile, wherein the rear end of the laying trolley isrotatably provided with a rotary shaft for placing a film roll, and is further provided with a driving clamping discharging roller and a driven clamping discharging roller; the driving clamping discharging roller is connected to a servo motor; the servo motor is connected to a controller; and a plurality of photoelectric sensors for monitoring the rotation speed of a roller are further arranged ona rack. While the laying device is used, one end of a film is fixed through the fixing pile, the servo motor drives the driving clamping discharging roller and the driven clamping discharging rollerto outwards convey the film continuously; and moreover, the motion speed is further monitored through the photoelectric sensors, so that the film releasing speed is consistent with the motion speed ofthe laying trolley. Compared with the prior art, the concrete protective film laying device has the advantages of improving the laying efficiency, being not liable to have folds, and being high in laying quality.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

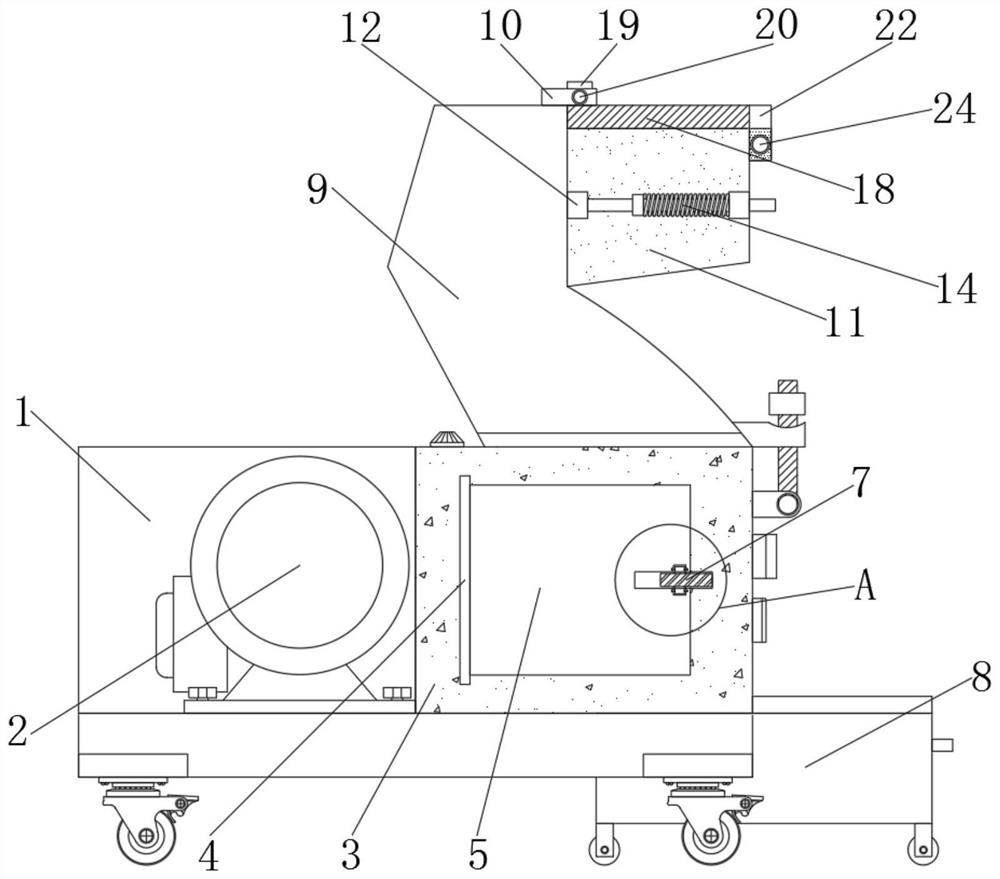

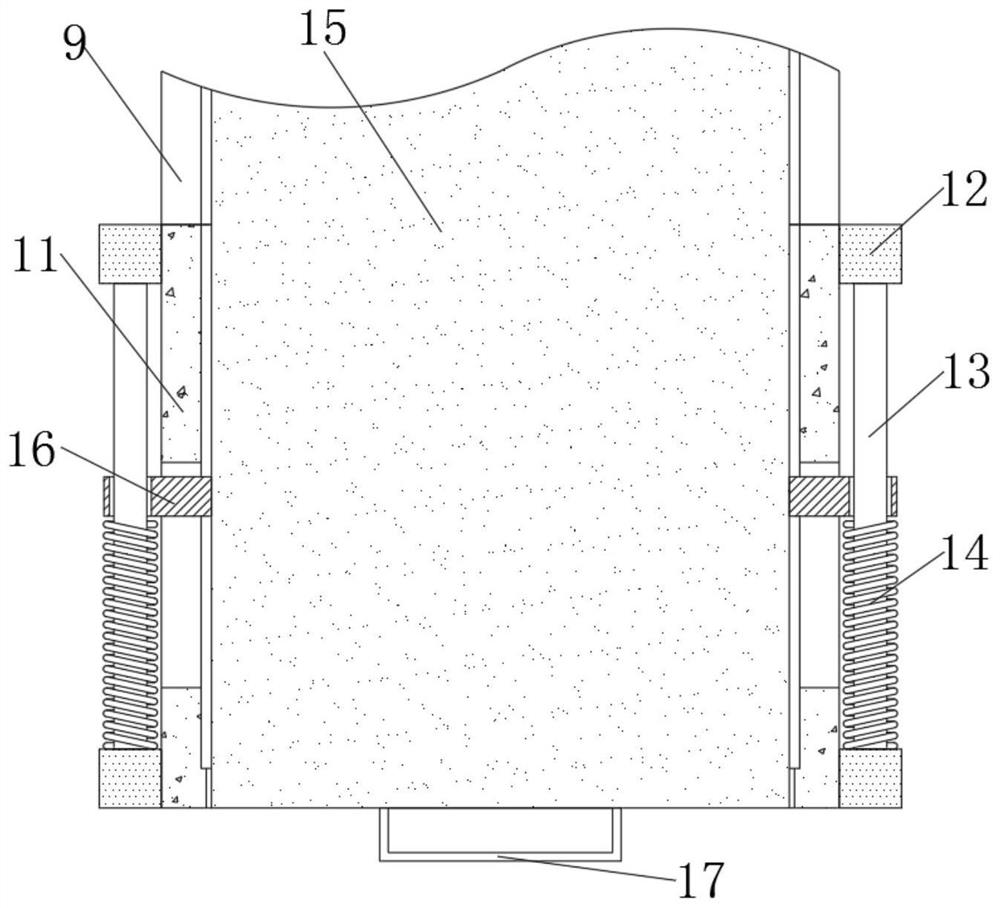

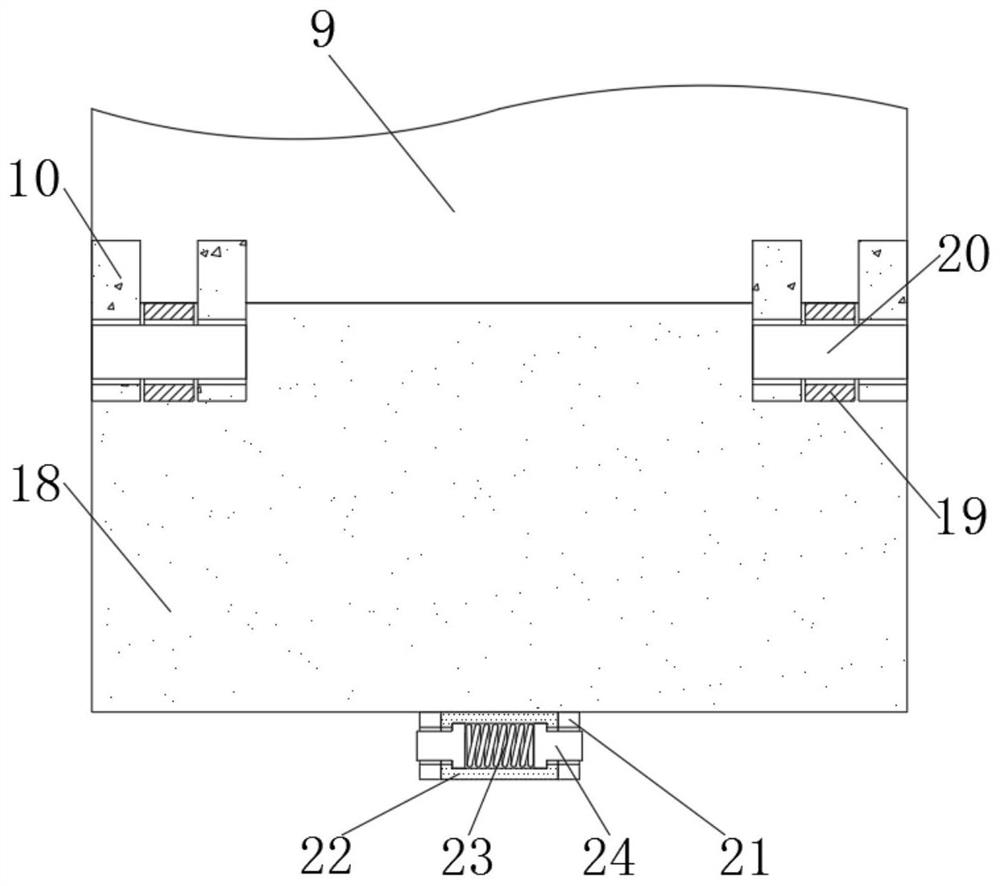

Dust-removal industrial material unloading machine

InactiveCN107720332AEasy to moveEasy to control the feeding speedConveyorsLoading/unloadingMotor vibrationElectric machinery

The invention discloses a dust-removing industrial material unloader, which comprises a support device and a discharge device; The discharge door support plate; the lower left side of the discharge plate is connected with the left column through the connecting spring; the right end of the vibration motor is connected with the eccentric wheel through the rotating shaft; the right end of the dust collection box is connected through the dust suction pipe and The first suction fan is connected, and the left end of the dust collection box is connected with the second suction fan through a dust suction pipe; the device of the present invention is provided with a weighing sensor on the support plate of the discharge door. The hydraulic telescopic rod shrinks, and the material flows out; the vibration motor is placed under the unloading plate, and the vibration motor drives the unloading plate to vibrate. The larger the vibration amplitude of the vibration motor, the faster the material feeding speed, and has the function of controlling the material feeding speed; this device The utility model has the characteristics of simple manufacturing process, strong practicability and good discharge effect.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

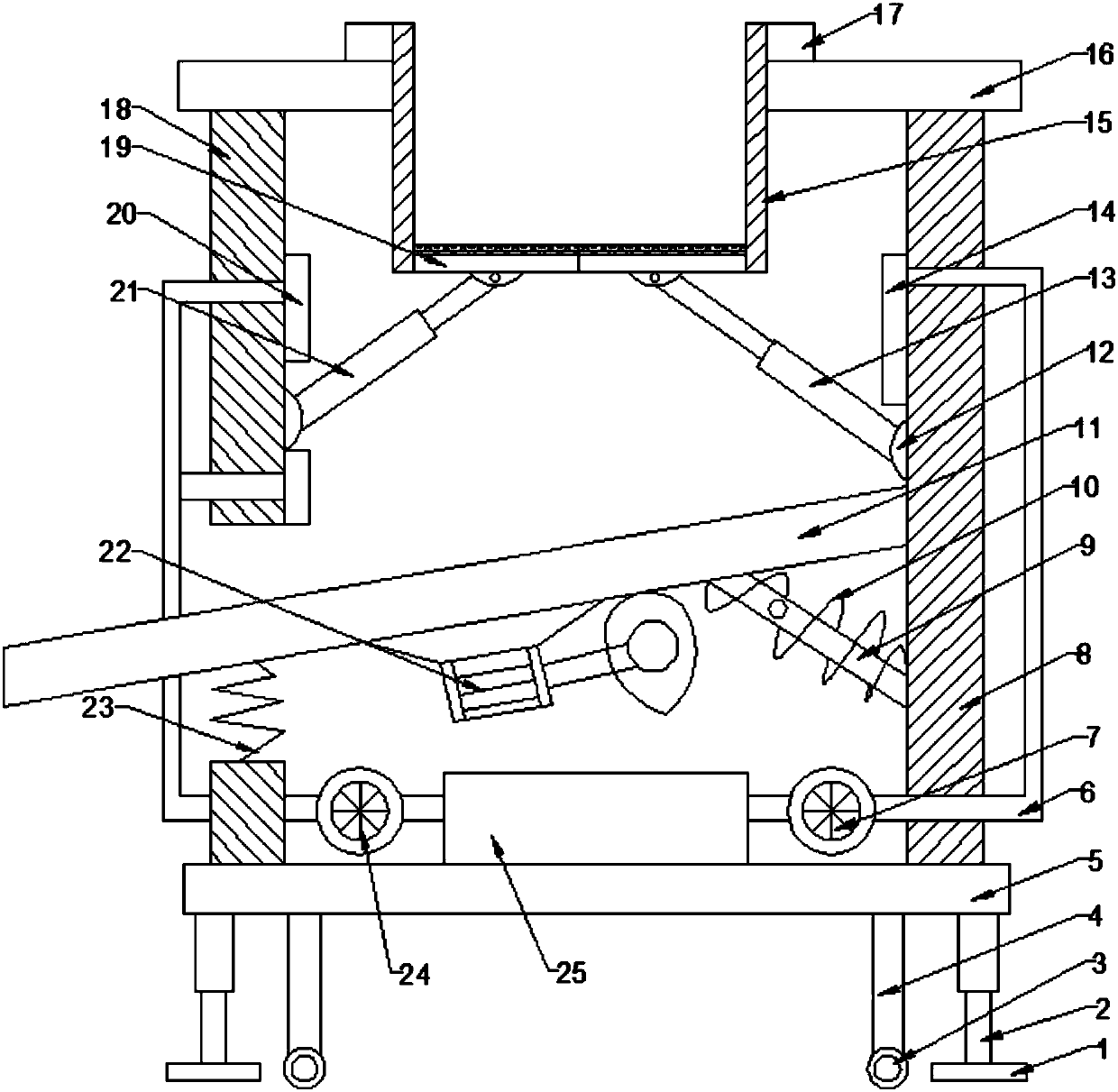

Vanadium slag pelleting device

InactiveCN109999721AImprove Particle UniformityReduce labor intensityGranulation by pressingSlagPre compression

The invention discloses a vanadium slag pelleting device, and relates to the technical field of metallurgy. The problem that vanadium slag pellets prepared by a disc granulator are poor in uniformityand low in pelletizing rate is solved. According to the technical scheme, the vanadium slag pelleting device comprises a feeding system, a pre-pressing forming system and a screening system; the pre-pressing forming system comprises a pre-pressing hopper and a forming hopper; the feeding system is used for supplying materials to the pre-pressing hopper; a pre-pressing roller press and a first edgecutting machine are arranged in the pre-pressing hopper, wherein a discharging opening of the feeding system directly faces a gap between two pressing rollers of the pre-compression roller press, andthe first edge cutting machine is arranged below the pre-compression roller press; a forming pressing roller and a second edge cutting machine are arranged in the forming hopper, wherein a discharging opening of the pre-pressing hopper directly faces a middle line between two pressing rollers of the forming roller press, and the second edge cutting machine is arranged below the forming pressing machine; the screening system is arranged below a discharging opening of the forming hopper; and a finished product bin is connected on a screen of the screening system and a fine powder bin is arranged below the screen. The vanadium slag pelleting device is applicable to vanadium slag pelleting.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

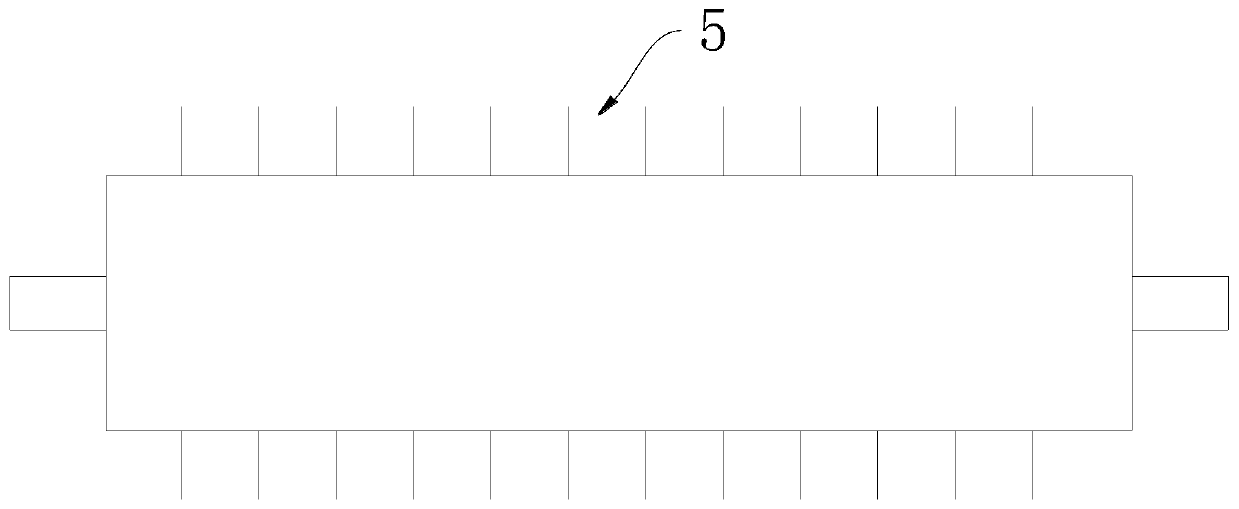

Electric control board conveying device for new energy vehicle

The invention discloses an electric control board conveying device for a new energy vehicle. The electric control board conveying device comprises a bottom plate, the top of the bottom plate is fixedly connected with two symmetrical support legs, the top ends of the two support legs are fixedly connected through a conveying U-shaped plate, a mounting bearing seat is fixedly connected to the innersurfaces of the front surface and the back surface of the conveying U-shaped plate, and the inner surfaces of the sides, getting close to each other, of the two mounting bearing seats are fixedly connected through a driven roller. According to the electric control board conveying device, a stepping motor is arranged to enable a threaded rod to rotate, a guiding sliding rod and a guiding bearing seat are arranged to limit a threaded block, the threaded rod rotates to move the threaded block in the up and down direction, the threaded block moves up and down to control angle changes caused when aforce applying rod extrudes a discharging plate to rotate, a worker can conveniently manage and control the discharging effect by reasonably controlling the inclined angle of the discharging plate, and the effect of facilitating the worker in managing and controlling the transportation efficiency is achieved.

Owner:柳州英飞科技有限公司

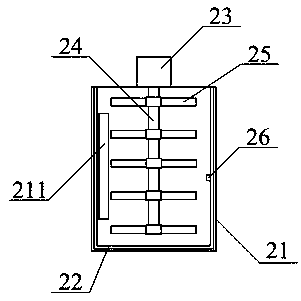

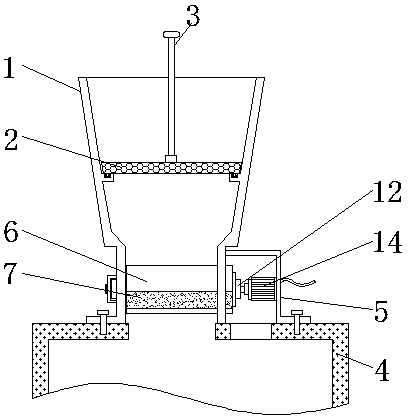

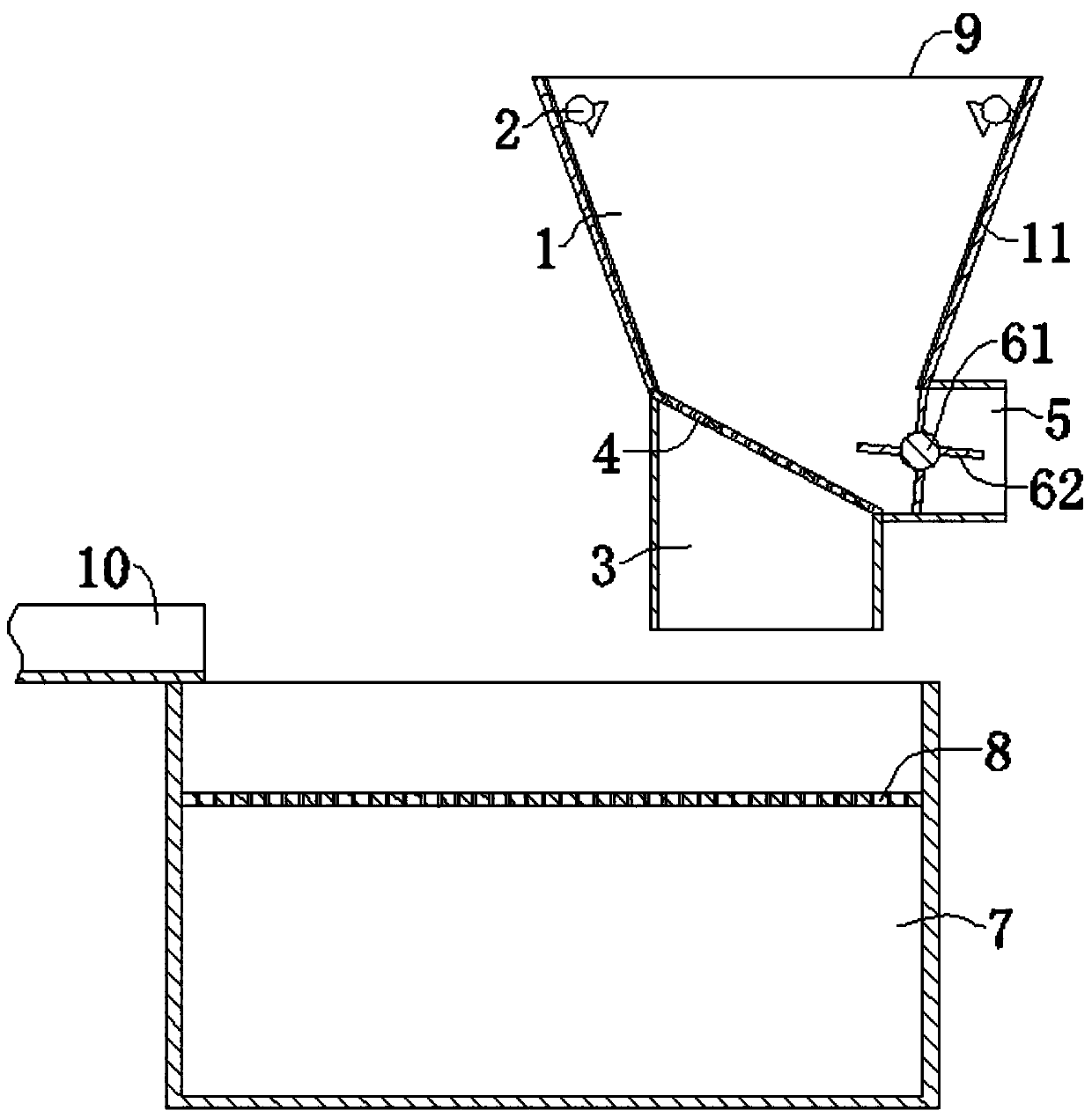

Anti-blocking feeding hopper with supplying speed convenient to control for production of insulation boards

ActiveCN110371702ANo cloggingEasy to control the feeding speedLarge containersLoading/unloadingPulp and paper industryRaw material

The invention discloses an anti-blocking feeding hopper with supplying speed convenient to control for production of insulation boards. The anti-blocking feeding hopper comprises a hopper body, a motor and a fixing bolt, a transverse plate is arranged inside the hopper body, the lower end of the hopper body is fixedly connected with the upper end of production equipment through bolts, the lower end of the hopper body is connected with a supplying roller in a penetrating mode, the supplying roller is internally connected with a baffle plate in a penetrating mode, the end, far away from the baffle plate, of a connecting plate is connected with a first spring in a welding mode, the end of the baffle plate is connected with a second spring, a fixing barrel is located inside the supplying roller, the inner-side end of the supplying roller is connected with the outer surface of a fixing roller, the output end of the motor is connected with the right end of a connecting shaft, and the fixingbolt is connected to the outer surface of the right end of the fixing barrel. According to the anti-blocking feeding hopper with the supplying speed convenient to control for production of the insulation boards, the supplying speed can be controlled conveniently, moreover, blockage can not be caused during supplying, and the function of filtering raw materials is achieved.

Owner:盐城市华科电子有限公司

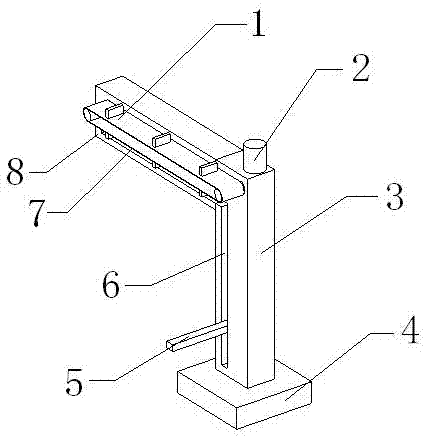

Lifting type loading device

InactiveCN108353822AEasy to add foodEasy to move and loadAnimal feeding devicesAvicultureEngineeringMechanical engineering

Owner:陈立国

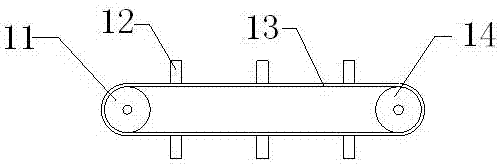

Rectangular-coordinate mechanical arm handling loading and unloading device

InactiveCN107283409ASolve the problem of unassisted horizontal movement function and limited useEasy to installProgramme-controlled manipulatorBall screwRectangular coordinates

The invention provides a loading and unloading device for a Cartesian manipulator, comprising a power roller, a toggle plate, a transmission belt, a driven roller, a motor, a ball screw, a hollow cavity, a ball nut pair and a square plate, and the power roller is installed on On the left side of the front end of the horizontal plate, the driven roller is installed on the upper side of the front end of the vertical plate, the power roller is connected to the driven roller through a transmission belt, and the driving plate is installed on the outer surface of the transmission belt. The purpose of the present invention to convert the vertical motion of the manipulator into horizontal motion is achieved. The motor is installed on the end surface of the vertical plate, the ball screw is assembled inside the hollow cavity, and the ring side of the ball screw is equipped with a ball As for the nut pair, a square plate is assembled on the annular side of the ball nut pair. This design improves the stability of the present invention. The present invention is easy to use, simple to operate, good in stability and high in reliability.

Owner:夏百庆

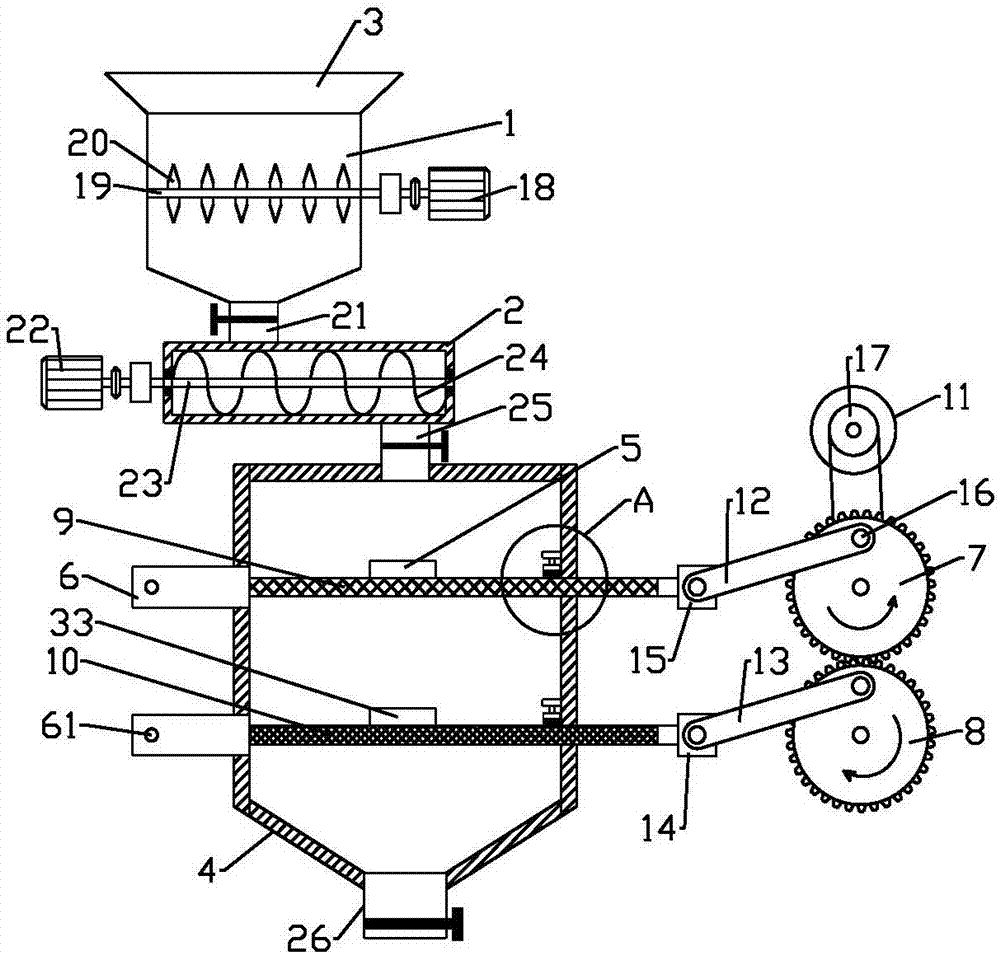

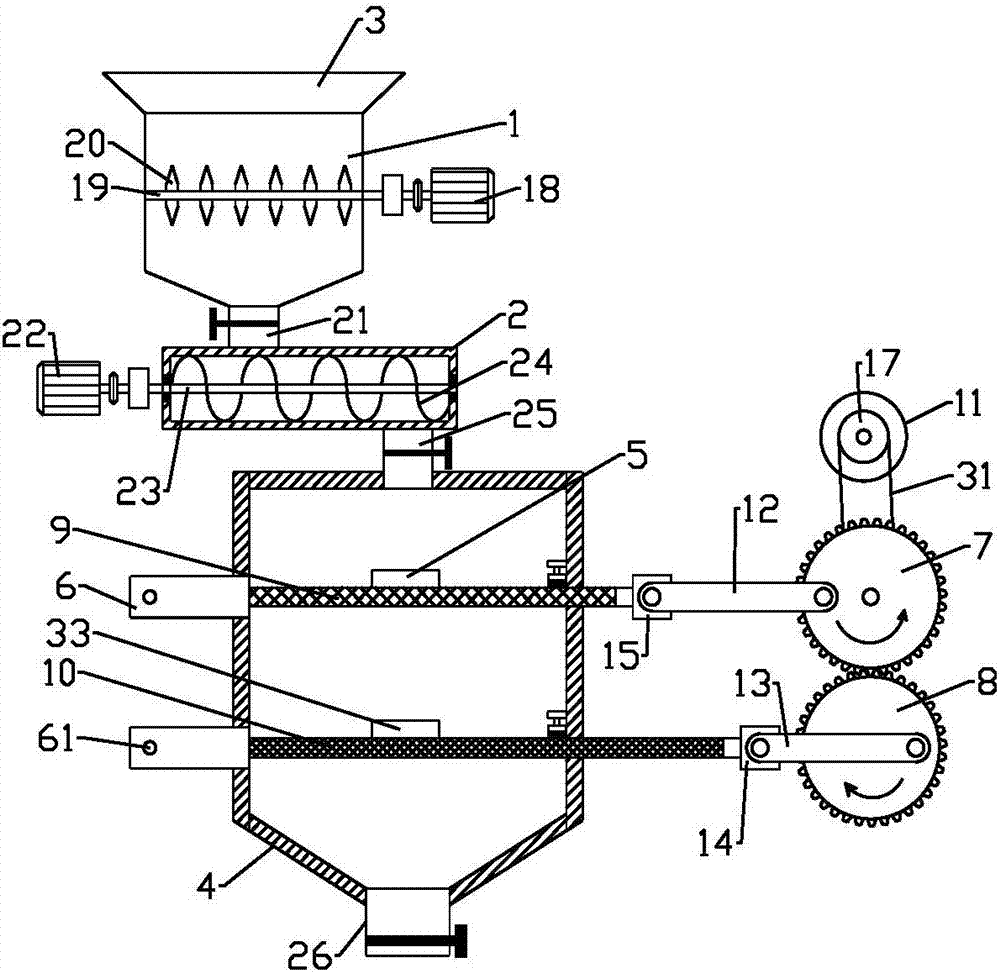

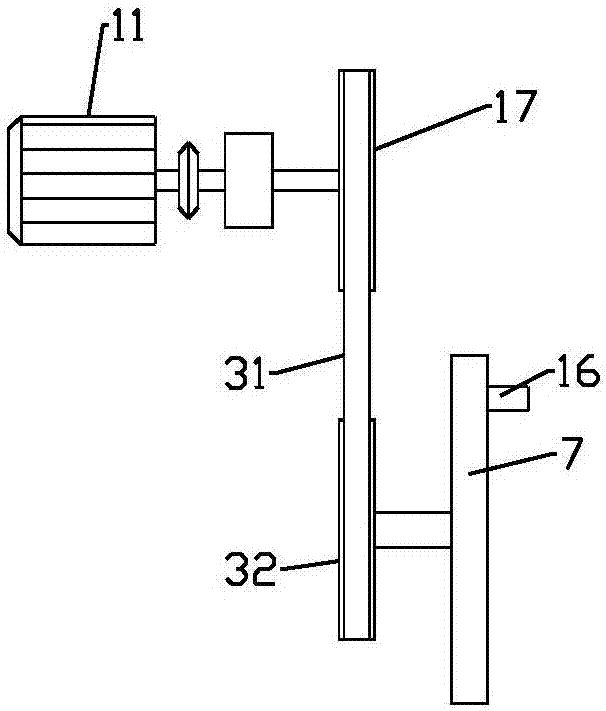

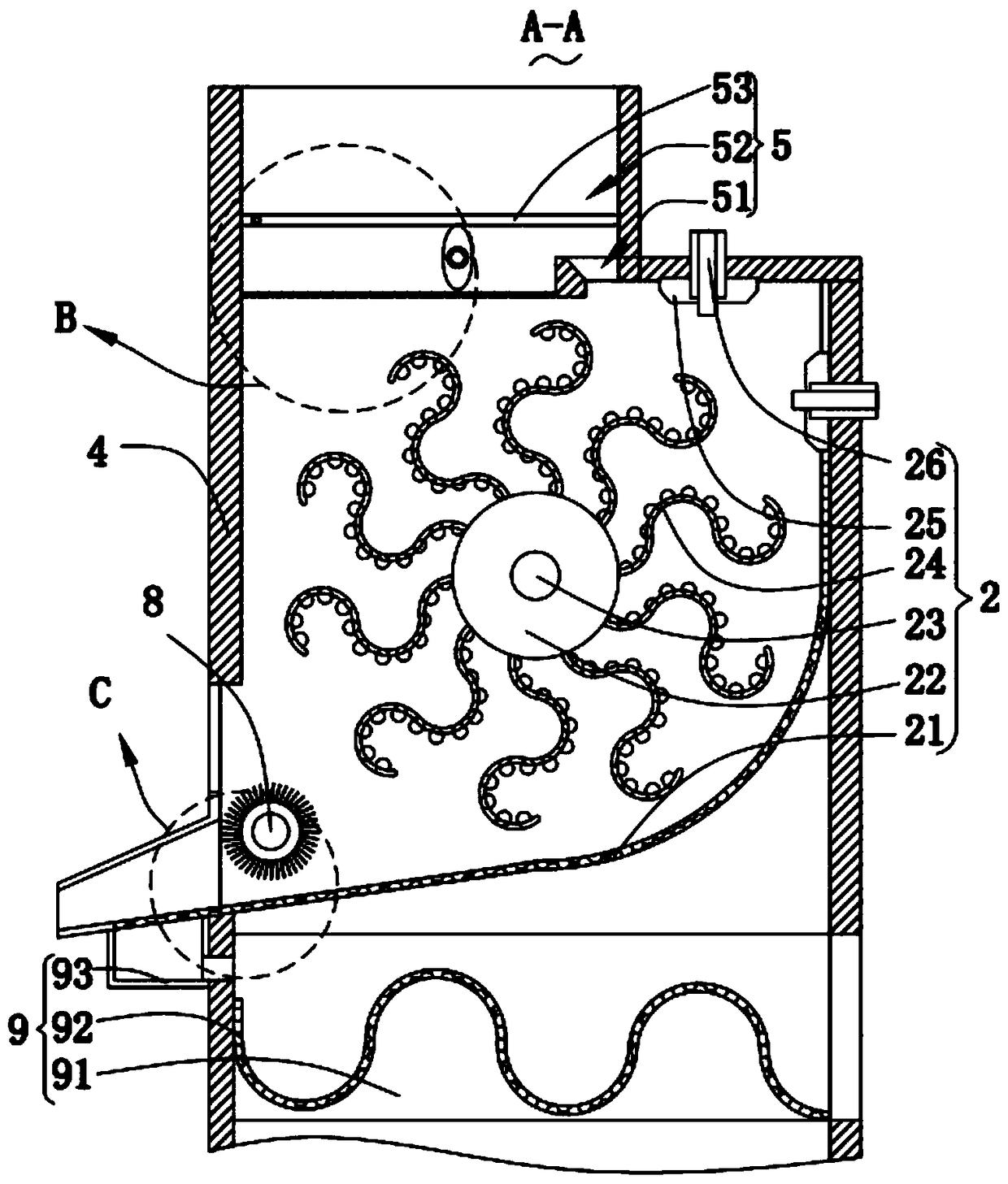

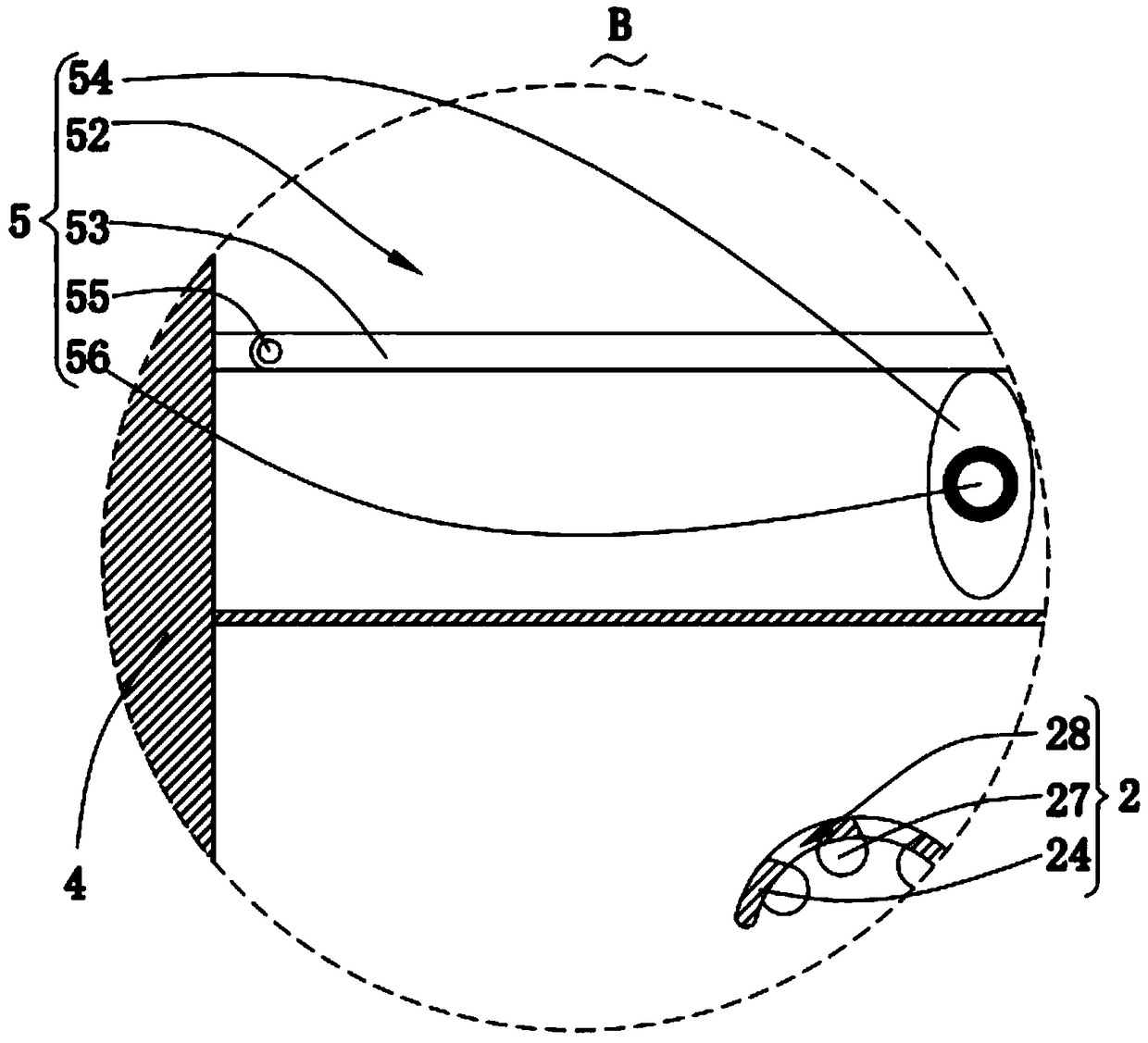

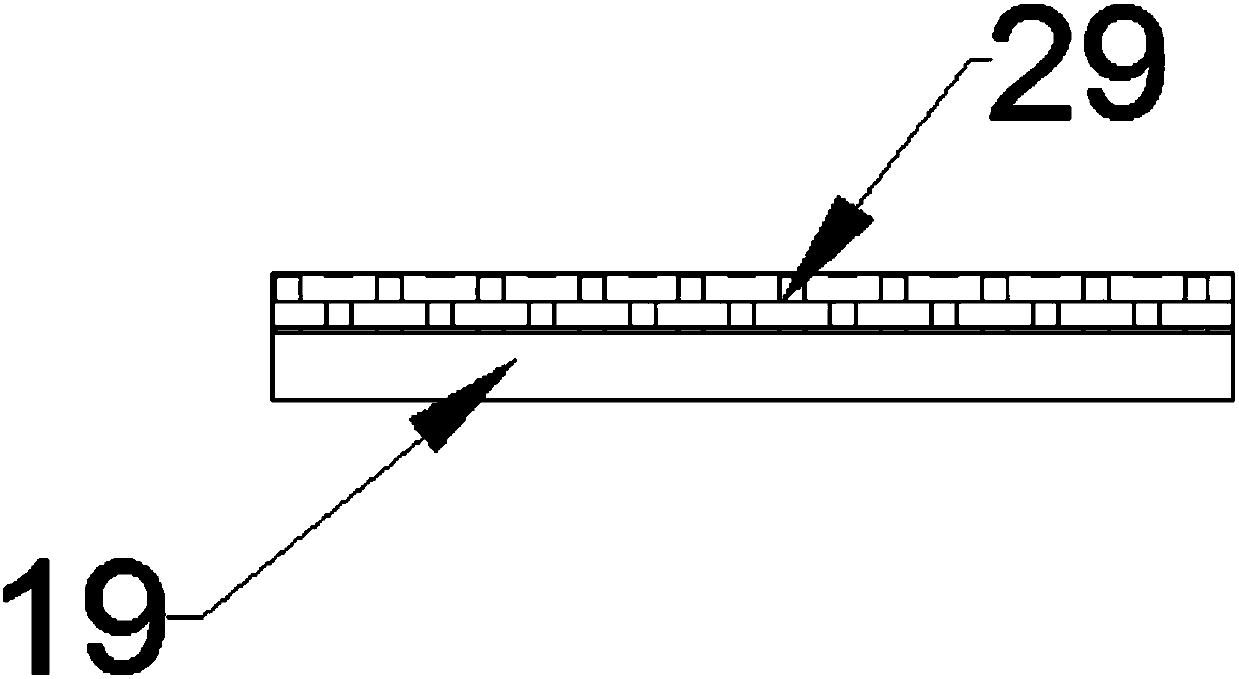

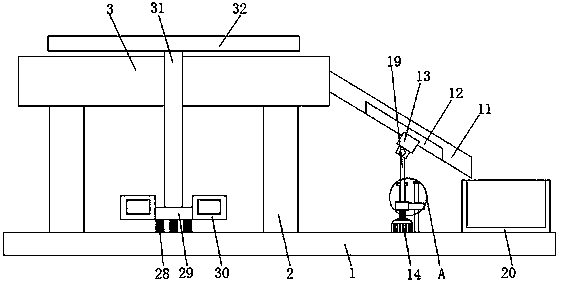

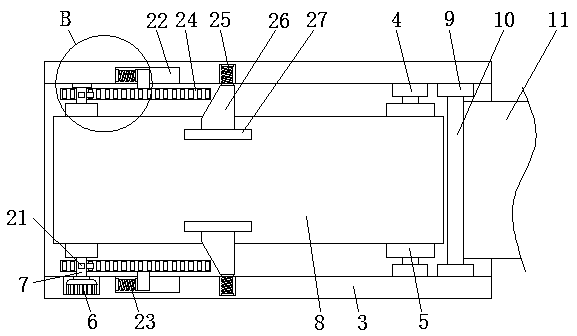

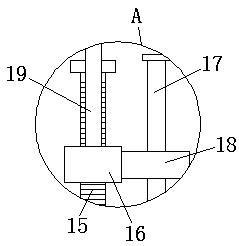

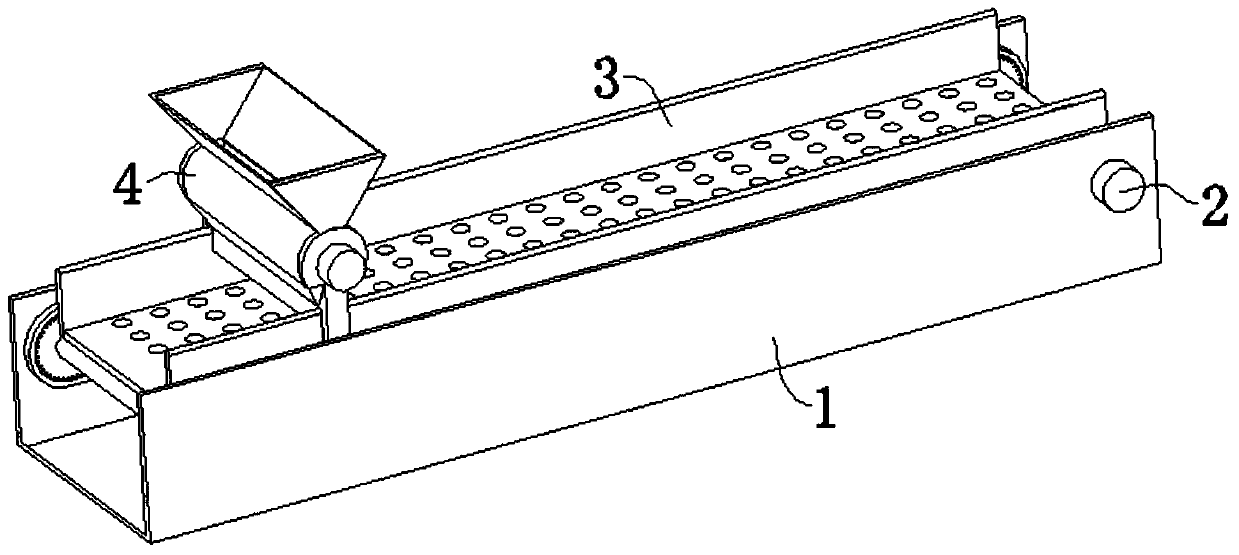

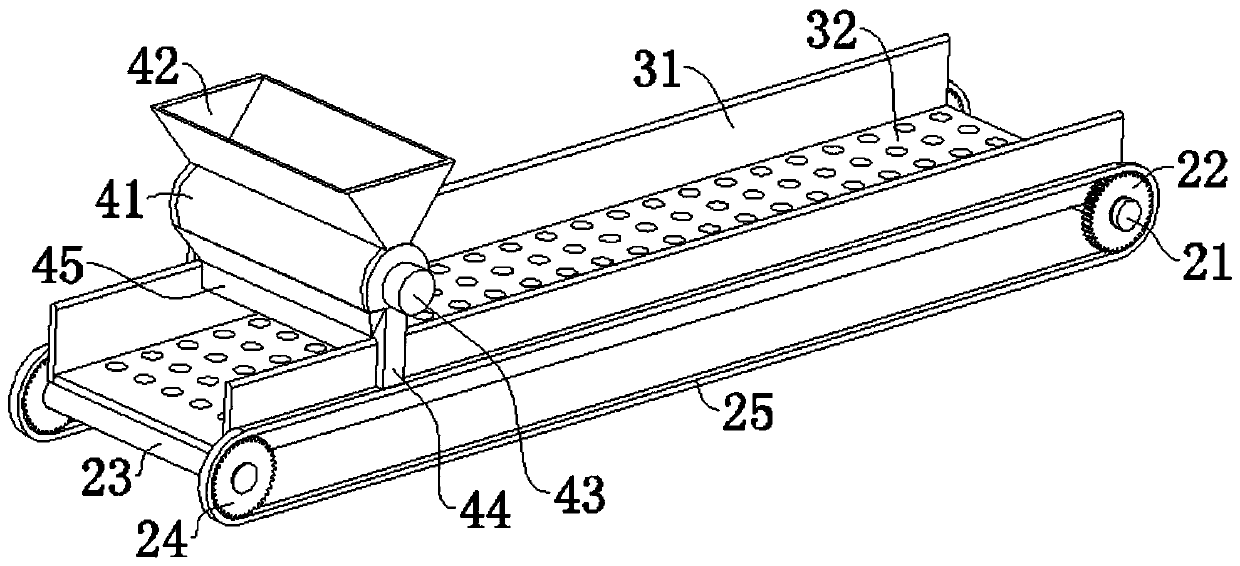

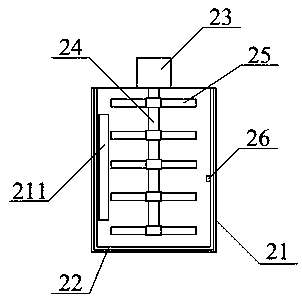

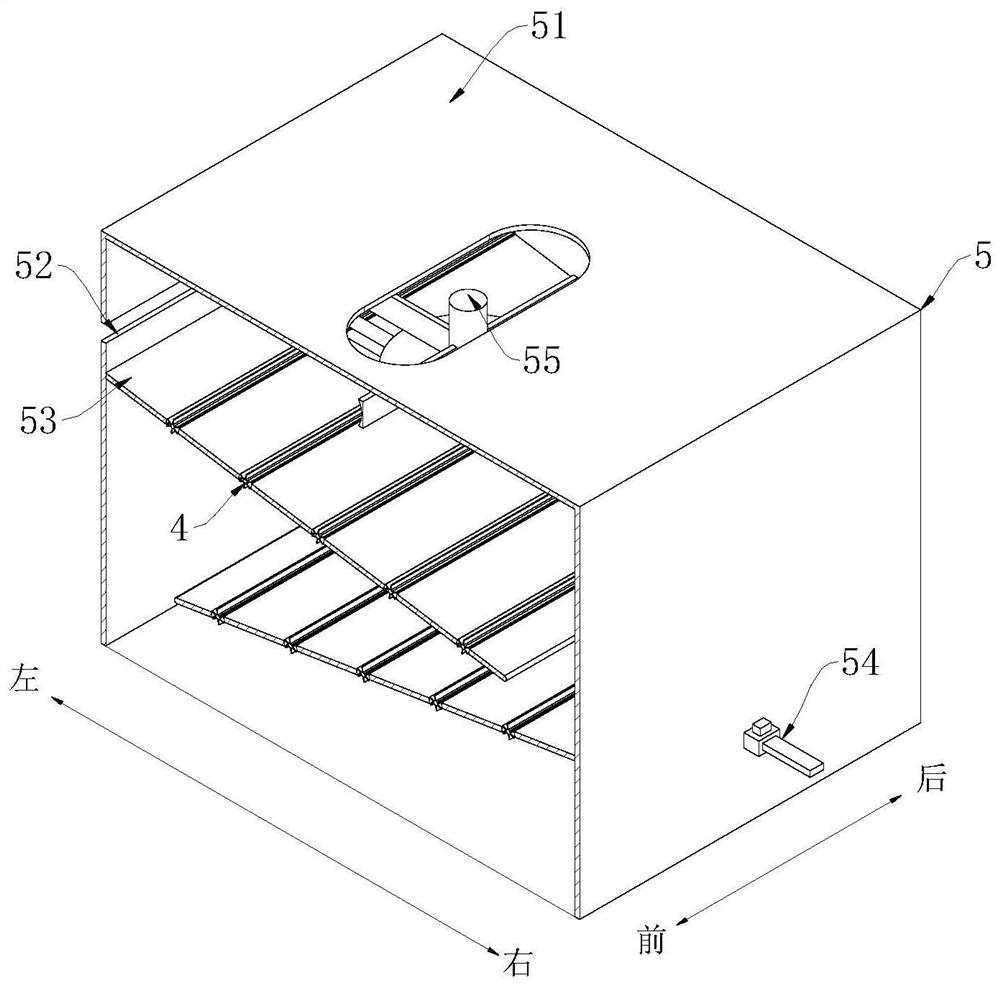

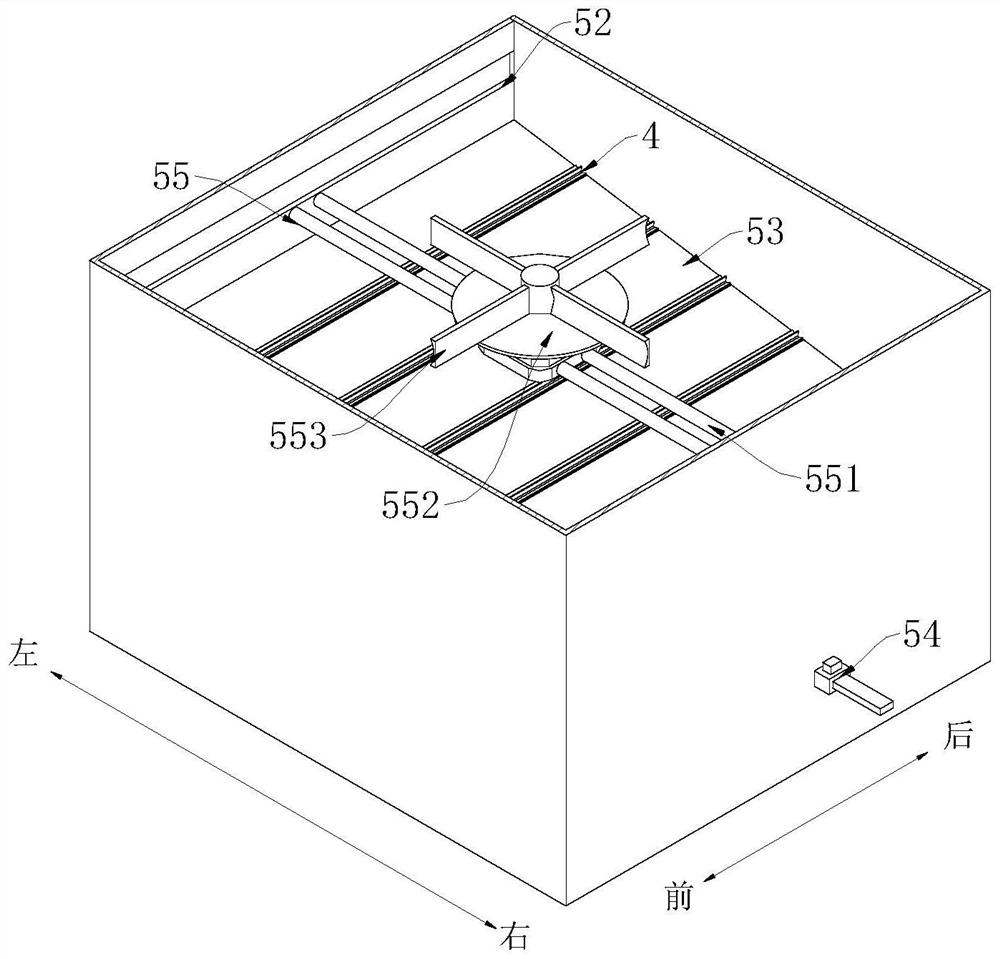

Withering trough convenient for spreading

InactiveCN110583806AEasy to control the feeding speedSolve the time-consuming and labor-consuming problem of manual spreadingPre-extraction tea treatmentBlack teaAgricultural engineering

The present invention discloses a withering trough convenient for spreading and belongs to the technical field of tea leaf processing. The withering trough comprises a withering trough body and also comprises a driving device, a machine box and a spreading device; the driving device is fixed on the machine box and also used for driving the spreading device to slide back and forth along a length direction of the withering trough body; the withering trough body is fixed on the machine box; the spreading device comprises a barrel body, a material feeding hopper, a material discharging device, a fixing block and a spreading opening, the material feeding hopper and the spreading opening are respectively located at a top part and a bottom part of the barrel body, and the spreading opening is located above the withering trough body and used for spreading black tea in the barrel body on the withering trough body; the material discharging device is arranged on the barrel body and also used forcontrolling spreading speed of the black tea; and the fixing block is fixed on the barrel body and the driving device. The withering trough solves problems that artificial spreading consumes time andpower during a black tea withering process.

Owner:通道九层岭茶业有限公司

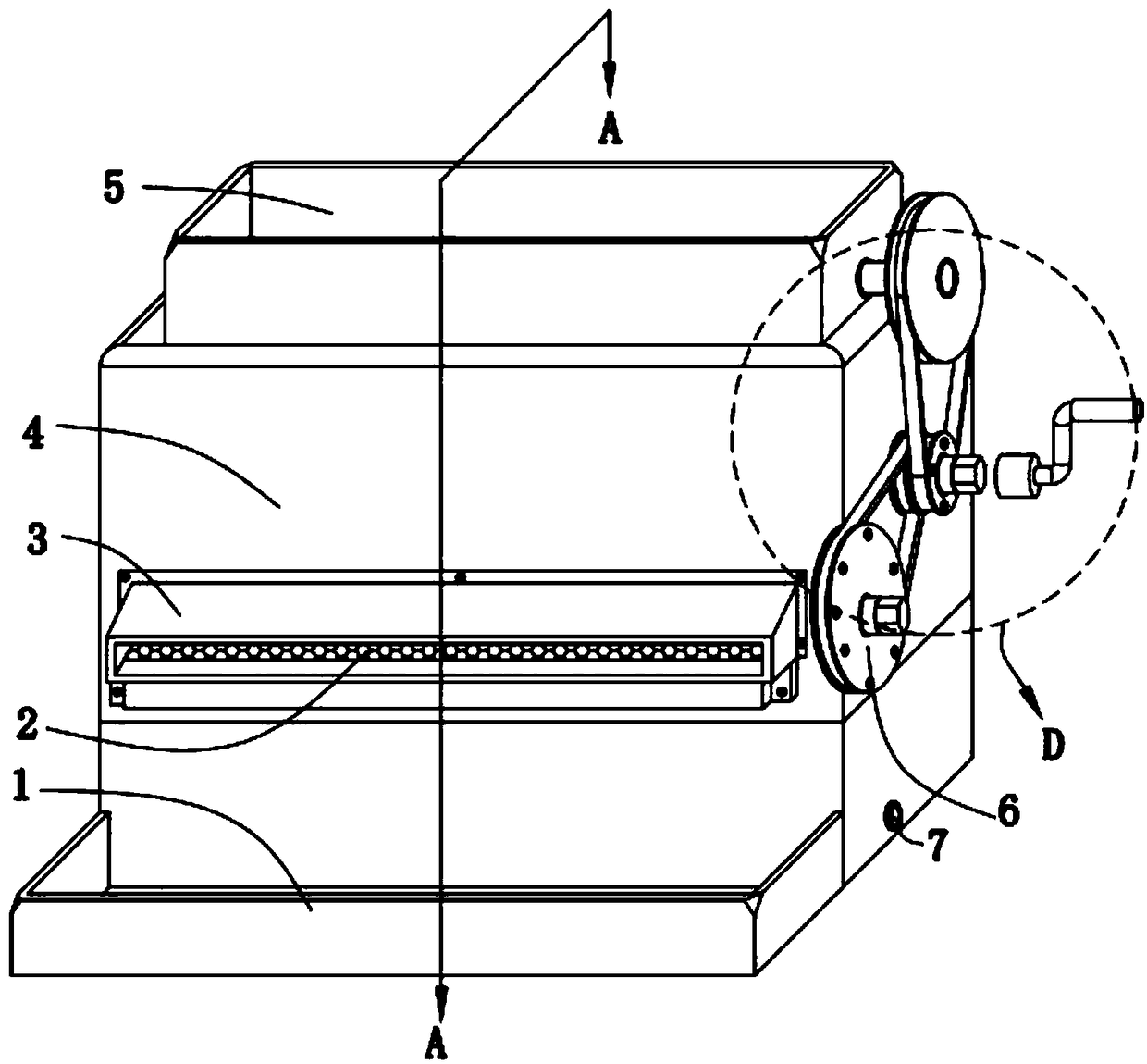

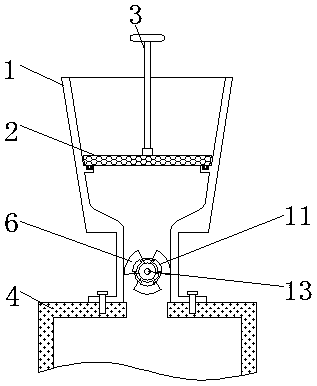

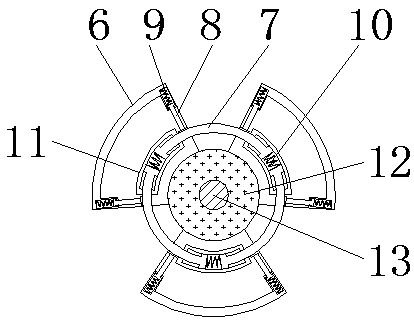

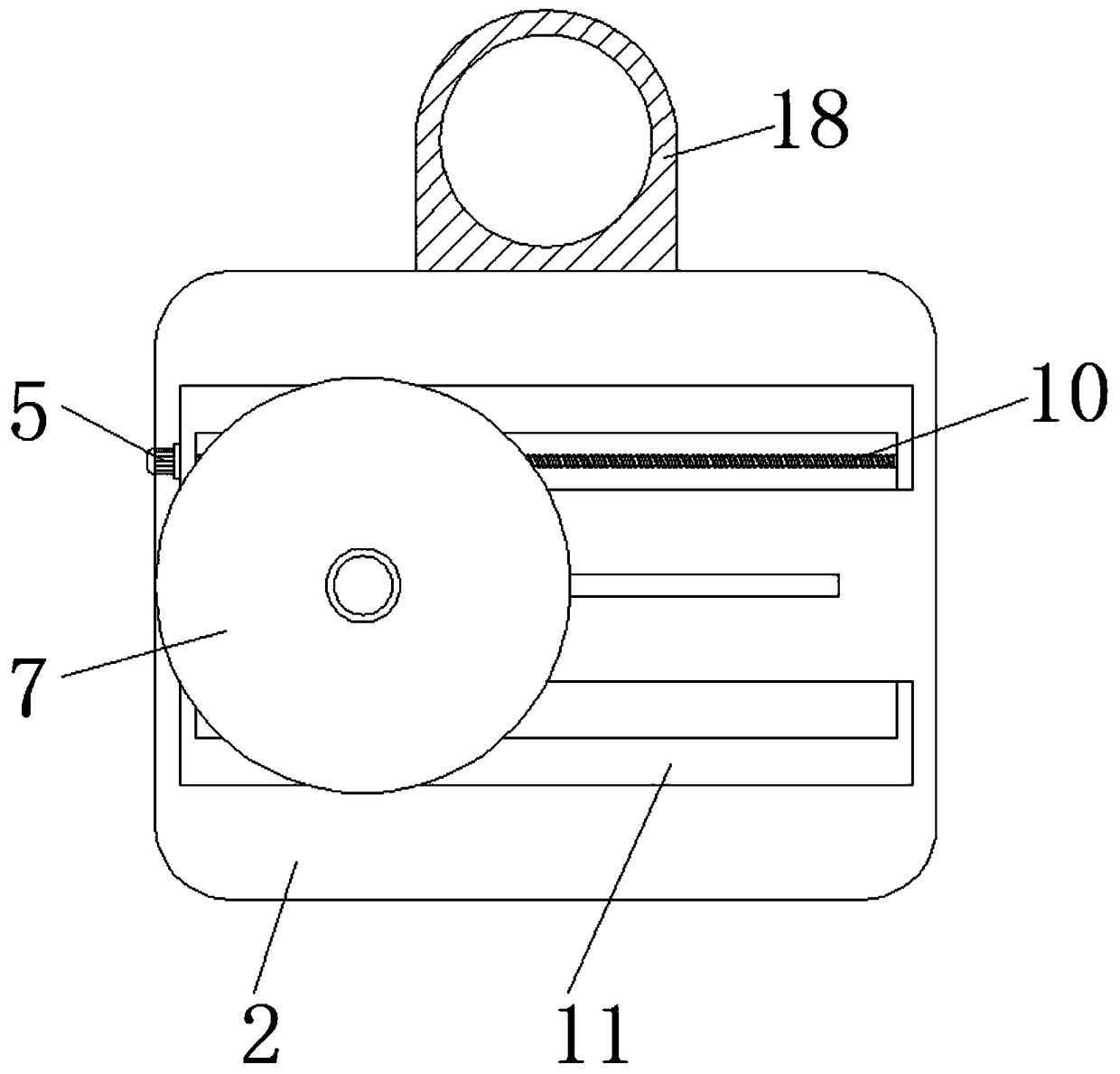

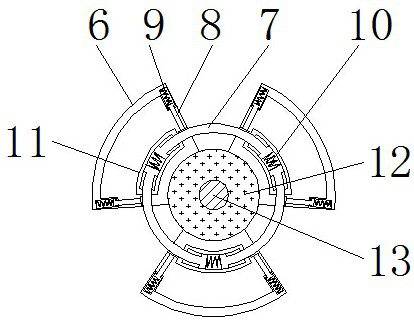

Solid sample division device

PendingCN107271243ADispersion is fast and efficientAvoid driftingPreparing sample for investigationElectric machineryPulley

The invention discloses a solid sample division device, comprising an outer barrel, partition plates, receiving troughs, a feeding hopper, a standard screen, a cover plate, a motor, a pulley, a belt groove, a belt, oblique distribution pipes, a feeding valve, a maintenance door, discharge valves, and support legs; the partition plates are radially fixed at the inner bottom of the outer barrel and divide the inner bottom of the outer barrel into a plurality of receiving troughs in equal area, the feeding hopper is vertically and rotationally arranged in the upper center of the outer barrel, the standard screen is fixed to the upper portion of the feeding hopper, the cover plate is horizontally and rotationally arranged at the upper portion of the standard screen, a motor having a vertical spindle is fixed to the outer side of the outer barrel, and the pulley is fixed to the spindle of the motor. Compared with the prior art, the solid sample division device has the advantages that solid samples can be divided quickly and efficiently, division uniformity for the solid samples is improved, sample drifting is effectively avoided, and experimental operations are greatly facilitated.

Owner:浙江云广检测技术有限公司

Coating device for drug production

InactiveCN109010061AImprove coating incompletenessUniform feedingPharmaceutical product form changeEngineeringConstant speed

The invention discloses a coating device for drug production. The coating device comprises a material receiving box. The outer wall of the top of the material receiving box is fixedly provided with acoating box through screws. A fixing table is fixed to the outer wall of the top of the coating box through screws. Screw rod mounting holes are formed in the outer walls of the two sides of the fixing table. The inner walls of the two screw rod mounting holes are connected with the same screw rod through bearings. An adjusting motor is fixed on the outer wall of one side of the fixing table through a screw. The output shaft of the adjusting motor is fixed to the outer wall of one end of the screw rod through a coupler. A sliding table sliding chute is formed in the outer wall of the top of the fixing table. The inner wall of the sliding table sliding chute is connected with a sliding table in a sliding mode. According to the coating device, drugs can be dispersed in the coating box, and the phenomenon that the coating is incomplete due to the accumulation of drugs can be improved. The blanking can be realized at a constant speed and the blanking speed can be conveniently controlled. The probability of the phenomenon that materials block a blanking port can be reduced. The production efficiency can be improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

Preparation method and preparation device of eel compound feed

PendingCN112970978APrevent enteritisPromote absorptionSievingFood processingBiotechnologyAnimal science

The invention discloses a preparation method and a preparation device of an eel compound feed, and relates to the technical field of feed preparation. The preparation method of the eel compound feed comprises the following raw materials in parts by weight: 60-70 parts of white fish meal, 10-15 parts of shrimp meal, 10-15 parts of corn flour, 8-10 parts of wheat gluten flour, 10-12 parts of fermented soybean meal, 3-5 parts of saccharomyces cerevisiae, 1-3 parts of an eel vitamin additive, 1-3 parts of an eel mineral additive, 3-5 parts of a traditional Chinese medicine herb extracting solution and purified water. The preparation method comprises the following steps of preparing the raw materials, performing drying and performing granulation. According to the preparation method of the eel compound feed, the produced eel compound feed can effectively prevent the problem of eel enteritis, promote absorption and conversion of the feed by eels, meet requirements of the eels for various nutrient components, promote the conversion rate of the feed, effectively increase the food intake of the eels, and further increase the growth speed of the eels.

Owner:浙江金甲水产饲料有限公司

A concrete protective film laying device

ActiveCN111364784BReduce labor intensityAvoid uneven laying problemsRoads maintainenceBuilding material handlingMotor driveThin membrane

The invention provides a concrete protective film laying device, which includes a laying trolley and a fixed pile. The rear end of the laying trolley is rotatably provided with a rotating shaft for placing a film roll, and is also provided with an active clamping discharge roller and a driven clamping discharge roller. , wherein the active clamping discharge roller is connected to the servo motor, and the servo motor is connected to the controller; the frame is also provided with a plurality of photoelectric sensors for monitoring the rotation speed of the drum. When the laying device of the present invention is used, the film One end of the film is fixed by a fixed pile, and the servo motor drives the active clamping feeding roller and the driven clamping feeding roller to continuously convey the film outward, and also monitors the speed of motion through a photoelectric sensor, so that the speed of film release is consistent with the movement of the laying trolley. The speed is consistent. Compared with the prior art, the present invention not only improves the laying efficiency, but also is less prone to wrinkles and has high laying quality.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A high-efficiency road hot-melt marking machine that is easy to maintain

ActiveCN107675603BObserve the liquid levelEasy to observeRoads maintainenceElectric machineryProcess engineering

The invention provides a convenient-to-maintain and efficient road hot-melt ruling machine. The convenient-to-maintain and efficient road hot-melt ruling machine comprises a base, a stirring heating material box structure, a pushing handle, an intelligent control device, a ruling rope structure, a ruling wheel structure, a bottom wheel, a positioning guide rod structure, a tool storing box structure and a standby material box; and the stirring heating box material structure is welded to the left side of the upper portion of the base, and the pushing handle is welded to the left side of the upper portion of the stirring heating material box structure. According to the convenient-to-maintain and efficient road hot-melt ruling machine, by arranging a transparent observation window, convenientobservation of the liquid level height in a stirring box is facilitated; by arranging a stirring motor, a stirring shaft and a stirring rod, convenient and full stirring of raw materials in the stirring box is facilitated, so that liquid materials are mixed more evenly; one end of a buffering rod is inserted in a buffering groove, the other end of the buffering rod is in shaft connection to the left side of the upper portion of a guide wheel bracket, improving of the buffering effect when the ruling guide wheel touches the ground is facilitated, and the ruling guide wheel is prevented from being damaged by colliding with the ground; and by arranging scale lines, convenient measuring the distance between high equipment and curbstone is facilitated.

Owner:山东金圭交通工程有限公司

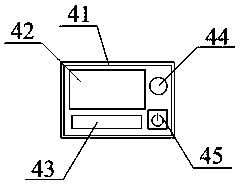

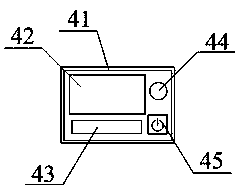

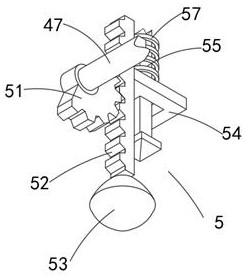

Crusher capable of conveniently preventing feeding port from being blocked

PendingCN112934450AEasy maintenanceEasy to control the feeding speedGrain treatmentsElectric machineryStructural engineering

The invention discloses a crusher capable of conveniently preventing a feeding port from being blocked. The crusher comprises a machine body, a plug pin, a connecting block and a pressing block, a motor is connected to the surface of the machine body, a control box is arranged on one side of the motor, a fixed shaft is arranged in the control box, and a maintenance plate is welded to one side of the fixed shaft; and a rotating wheel is arranged in the maintenance plate, a rotating wheel is connected to the interior of the plug pin in a penetrating mode, a charging box is connected to one side of the machine body, a flow guide box is connected to the top of the machine body, and a fixing rod is welded to the top of the flow guide box. According to the crusher capable of conveniently preventing the feeding port from being blocked, the outer wall of a flow limiting plate is tangent to the inner wall of a discharging box, an elastic linkage structure is formed between the flow limiting plate and the discharging box through a fixing block, a sliding rod, a connecting spring, a connecting block and a pull handle, by pulling the pull handle, the connecting block extrudes the connecting spring, the flow limiting plate slides in the discharging box, therefore, the discharging speed of the discharging box can be conveniently controlled, and the purpose of preventing blockage is achieved.

Owner:HANGZHOU FANGDING ELECTROMECHANICAL EQUIP

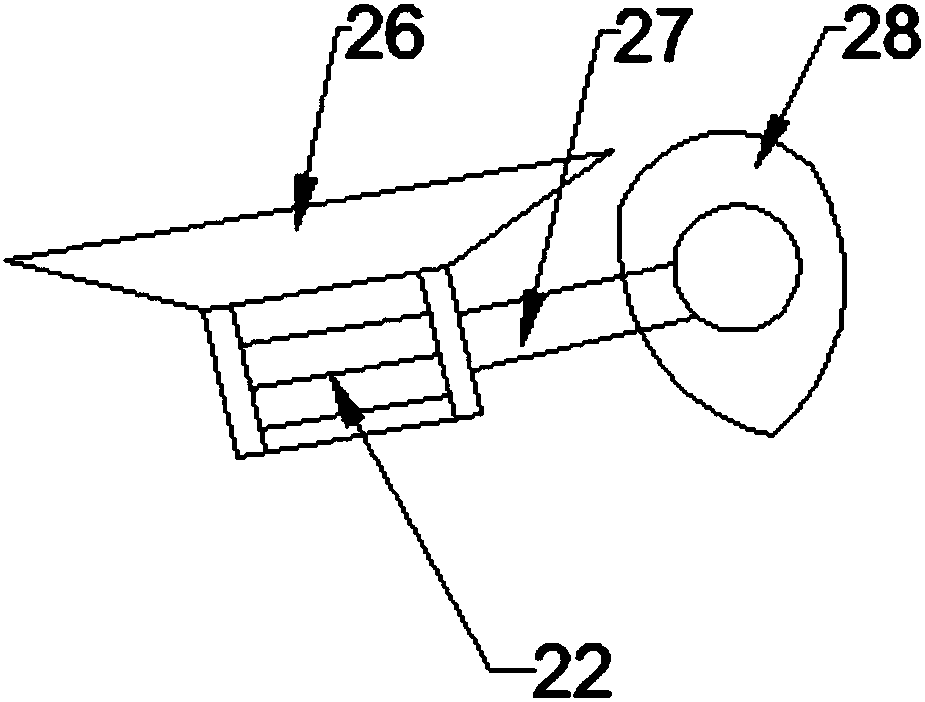

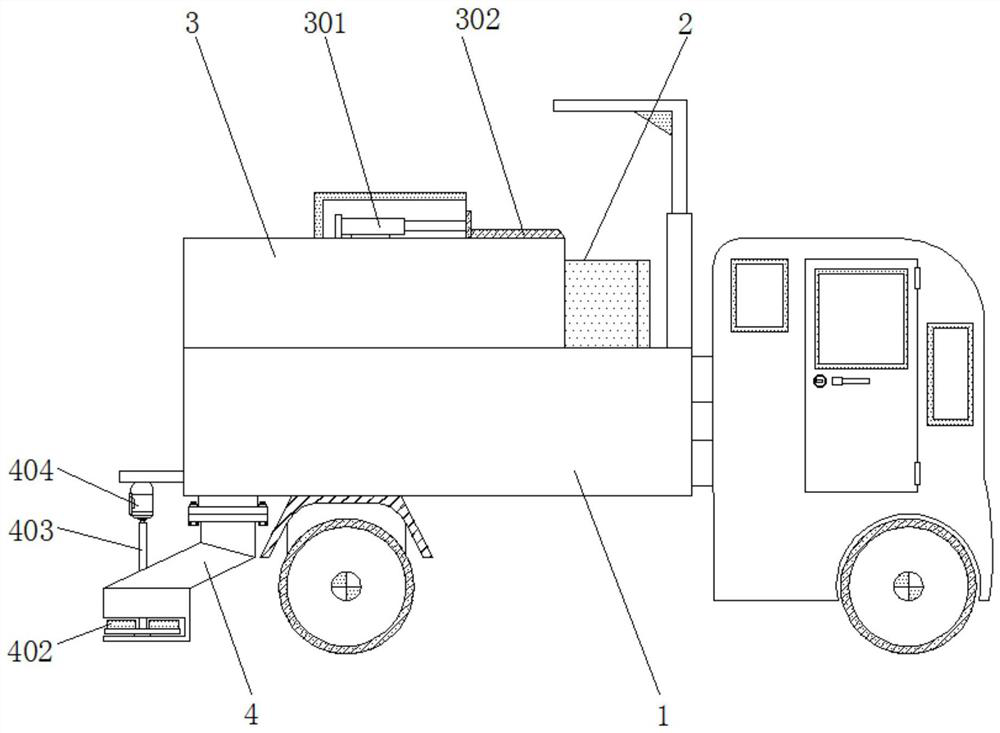

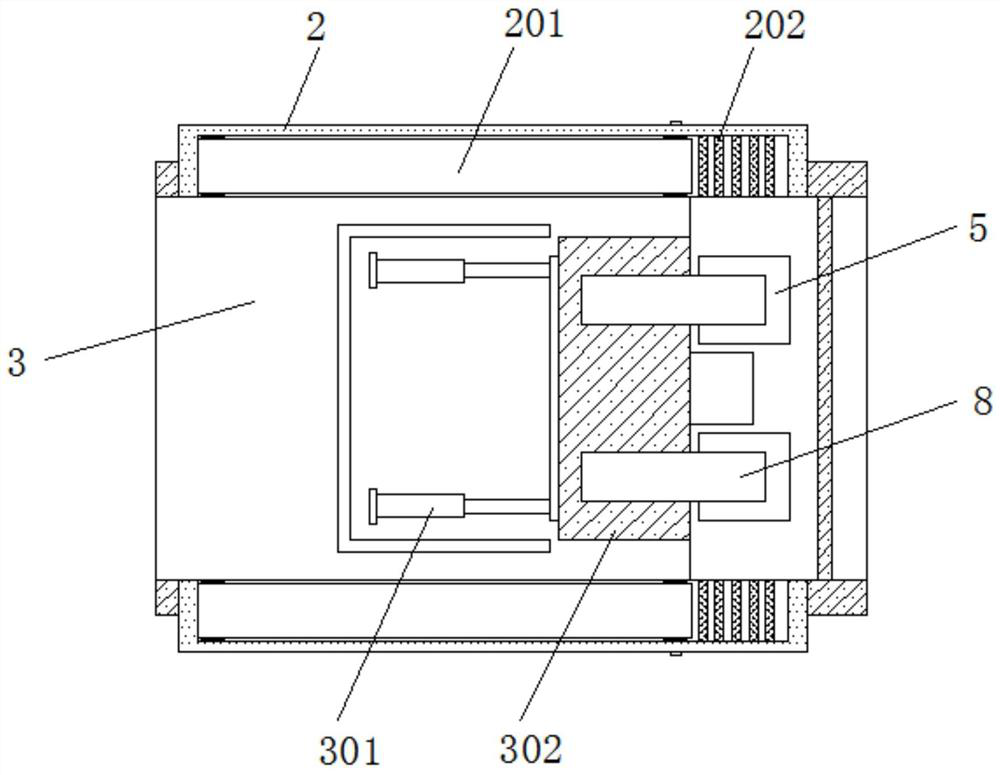

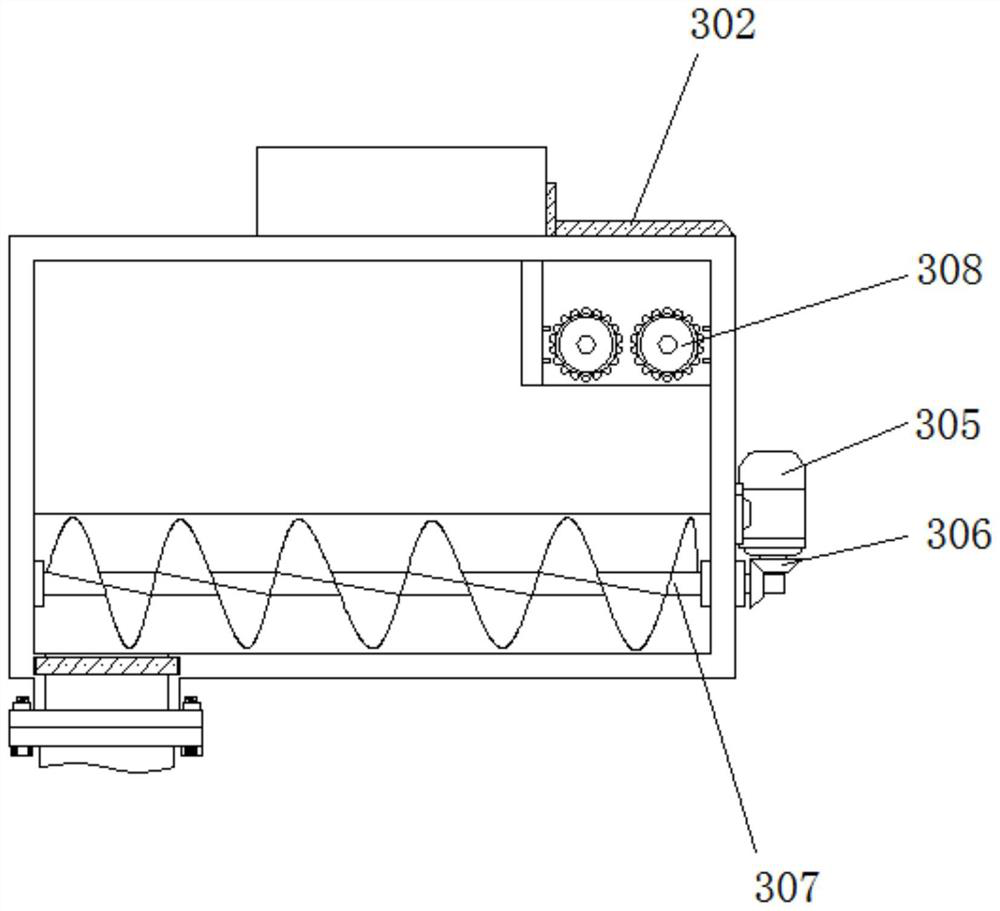

Engineering machinery particle spreading equipment for melting snow on road surface

PendingCN113718701AEasy to liftImprove battery lifeWay cleaningGrain treatmentsThermodynamicsSnow melting

The invention discloses engineering machinery particle spreading equipment for melting snow on a road surface. The equipment comprises a vehicle body, a material box, a first motor and a first hydraulic telescopic rod, a reserved frame is arranged on the vehicle body, the inner side surface of the reserved frame is connected with the material box, the material box is arranged in the vehicle body, a discharge pipe at the lower end of the material box is connected with a spreading pipe, a supporting frame is arranged on the right side of the material box, meanwhile, the supporting frame is arranged in the vehicle body, the first motor is arranged in the supporting frame, and the first motor is connected with a first rotating shaft. According to the engineering machinery particle spreading equipment for melting snow on a road surface, a pressing plate on the left side is pushed to extrude a pressing plate on the right side under the action of a fifth hydraulic telescopic rod, so that a puncture cone penetrates through a bagged snow melting agent, the bagged snow melting agent can be limited and fixed, the bagged snow melting agent can be lifted under the action of a first hydraulic telescopic rod, a rotating frame is driven to rotate through the first motor and the first rotating shaft, and the bagged snow melting agent on the reserved frame is transferred to the position above the material box for feeding and supplementing.

Owner:徐州山恒机械制造有限公司

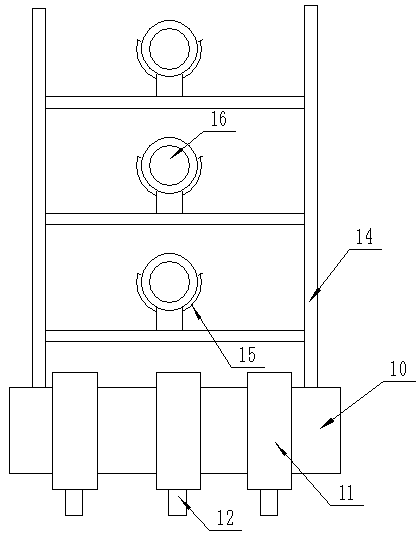

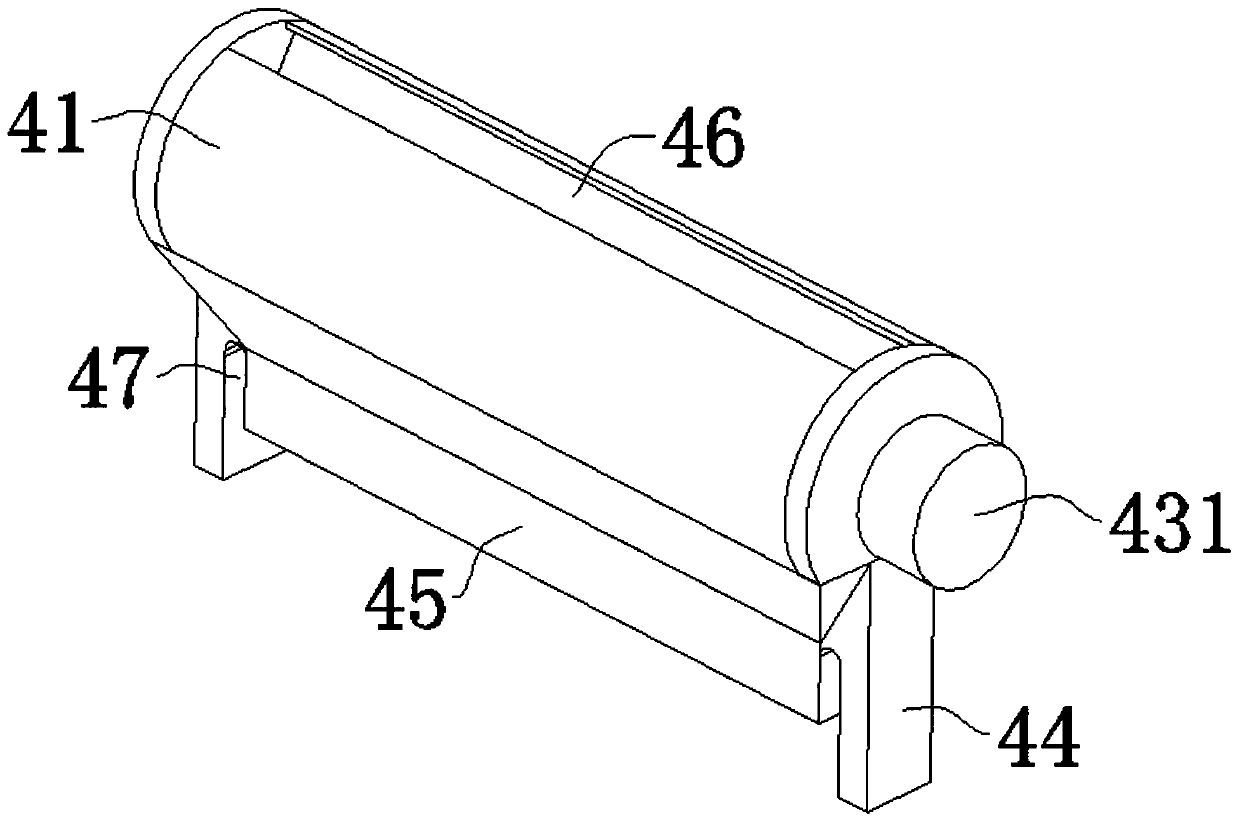

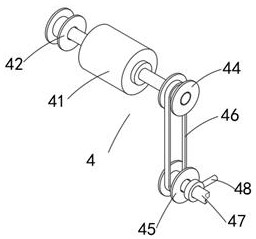

Large equipment for calculating and measuring cement output

InactiveCN109895260AEasy to control the feeding speedRealize card connectionMixing operation control apparatusSold ingredients supply apparatusStable stateDrive shaft

The invention discloses large equipment for calculating and measuring the cement output. The large equipment comprises a supporting framework, a discharging funnel arranged on the supporting framework, and a weighing device arranged on the supporting framework. The supporting framework comprises a square-shaped top beam and columns. The bottom of the discharging funnel is arranged in the square-shaped structure, and the bottom of the discharging funnel is provided with a discharging through opening. The weighing device comprises a belt, a transmission shaft and an auxiliary shaft. The transmission shaft and the auxiliary shaft are arranged on the columns on the two sides correspondingly. The transmission belt is arranged between the transmission shaft and the auxiliary shaft. A weight sensor is arranged below the transmission belt. The bottom faces of the columns are sleeved with bottom supports in a telescoping manner. Lead screws used for fixing the bottom supports are connected to the lower portions of the columns in a thread manner. An arc-shaped isolating plate is connected into the discharging funnel in a clamped manner. A plurality of small holes are uniformly formed in theisolating plate in a penetrating manner. A closed dustproof plug is clamped to each small hole. According to a metering platform, the isolating plate is utilized for controlling the discharging speedconveniently, thus the whole supporting framework is in the horizontal stable state conveniently by adjusting the columns, and therefore the cement output can be metered more accurately.

Owner:任宗俊

Blending device for producing waterborne epoxy anti-rust paint

PendingCN113522091APrecise control of feeding volumeImprove allocation efficiencyRotary stirring mixersMixer accessoriesEpoxyBLENDER/MIXER

The invention discloses a blending device for producing a waterborne epoxy anti-rust paint. The blending device comprises a supporting structure, the supporting structure comprises a horizontal base, two outer sliding rods fixedly connected with the horizontal base, a U-shaped inner sliding rod slidably connected with the outer sliding rods, an extension fixing plate fixedly connected with the U-shaped inner sliding rod, a plurality of supporting rods and a clamping ring. A stirring mechanism and a discharging control mechanism are installed on the extension fixing plate, a height control mechanism is slidably connected to the outer side of the horizontal base, and the stirring mechanism comprises a motor, a main rotating shaft, a rotating plate, a sleeve, a rotating rod, a stirring rotating plate, a transmission gear set, a chain plate, a fixing rod and a fixing rotating plate. Through mutual cooperation of all parts, the blending efficiency is greatly improved, the stirring mechanism is matched with the height control mechanism for stirring operation, the material mixing efficiency during blending is greatly improved, the material mixing effect is enhanced, the discharging speed and the discharging amount of different materials are conveniently controlled, and use is convenient and fast.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

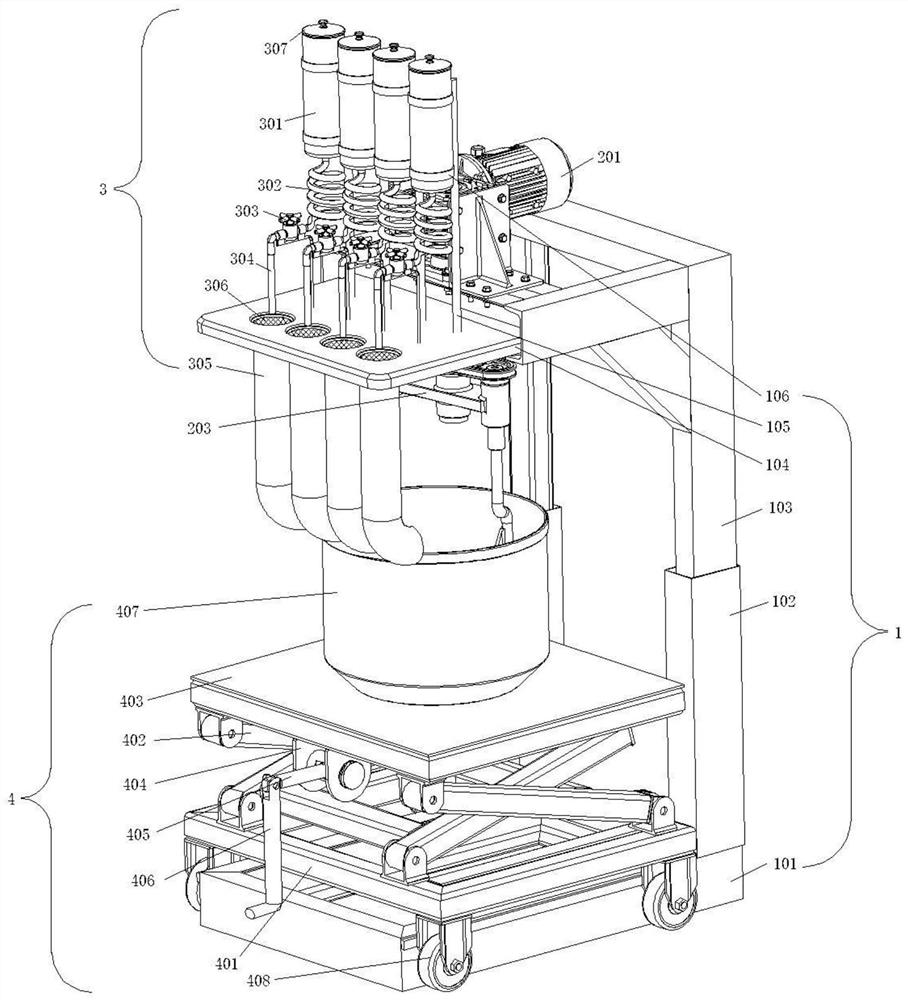

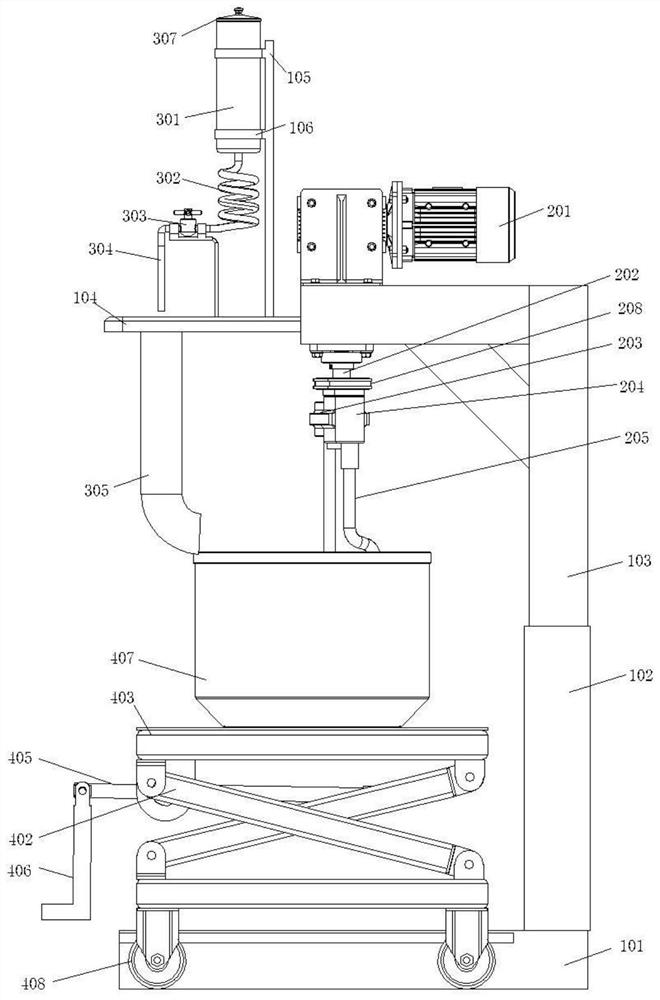

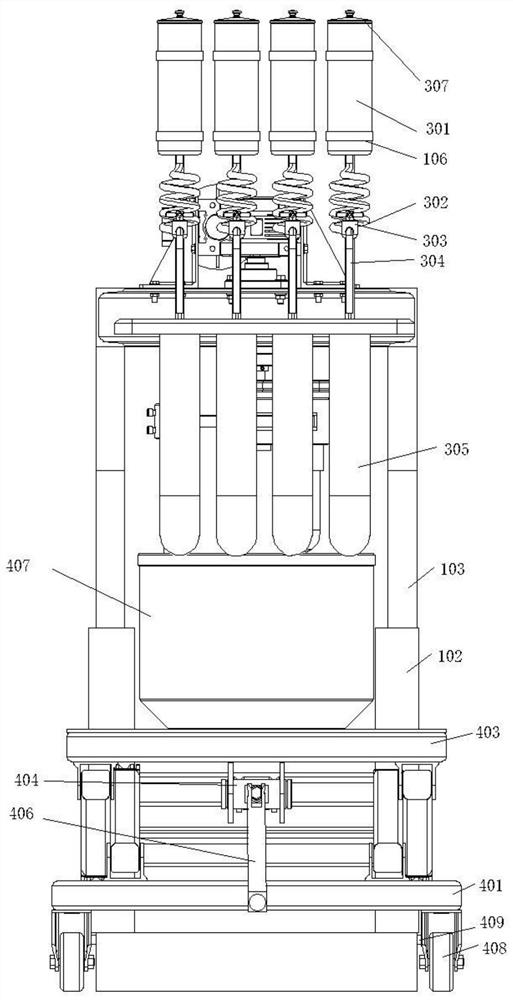

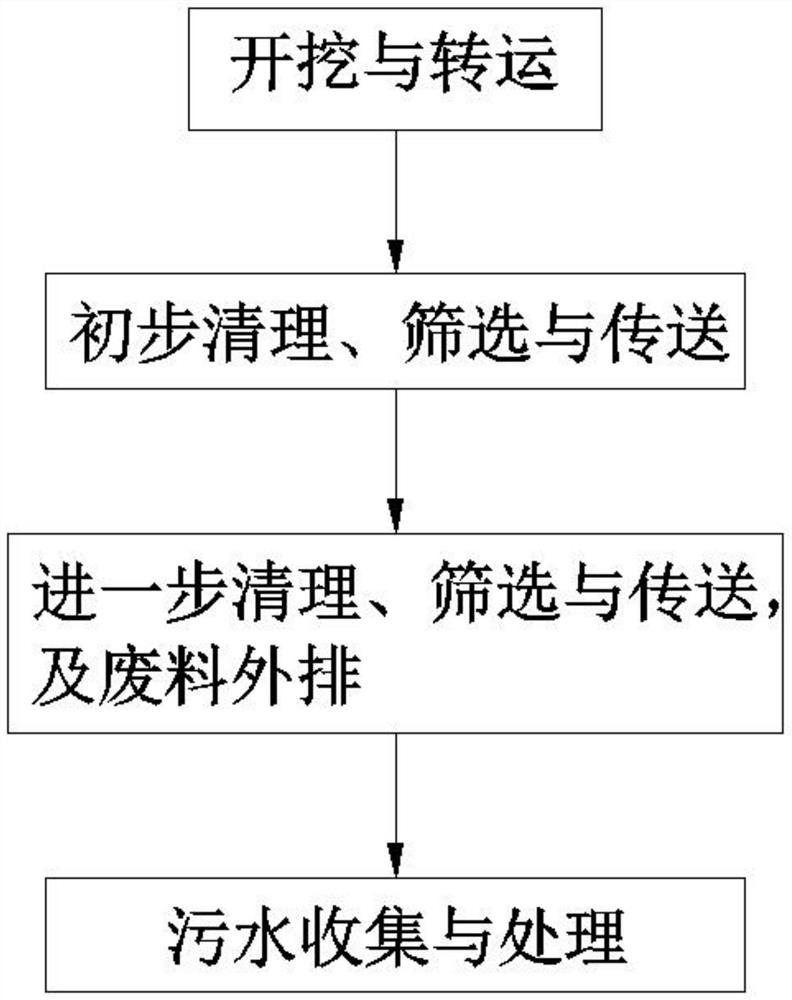

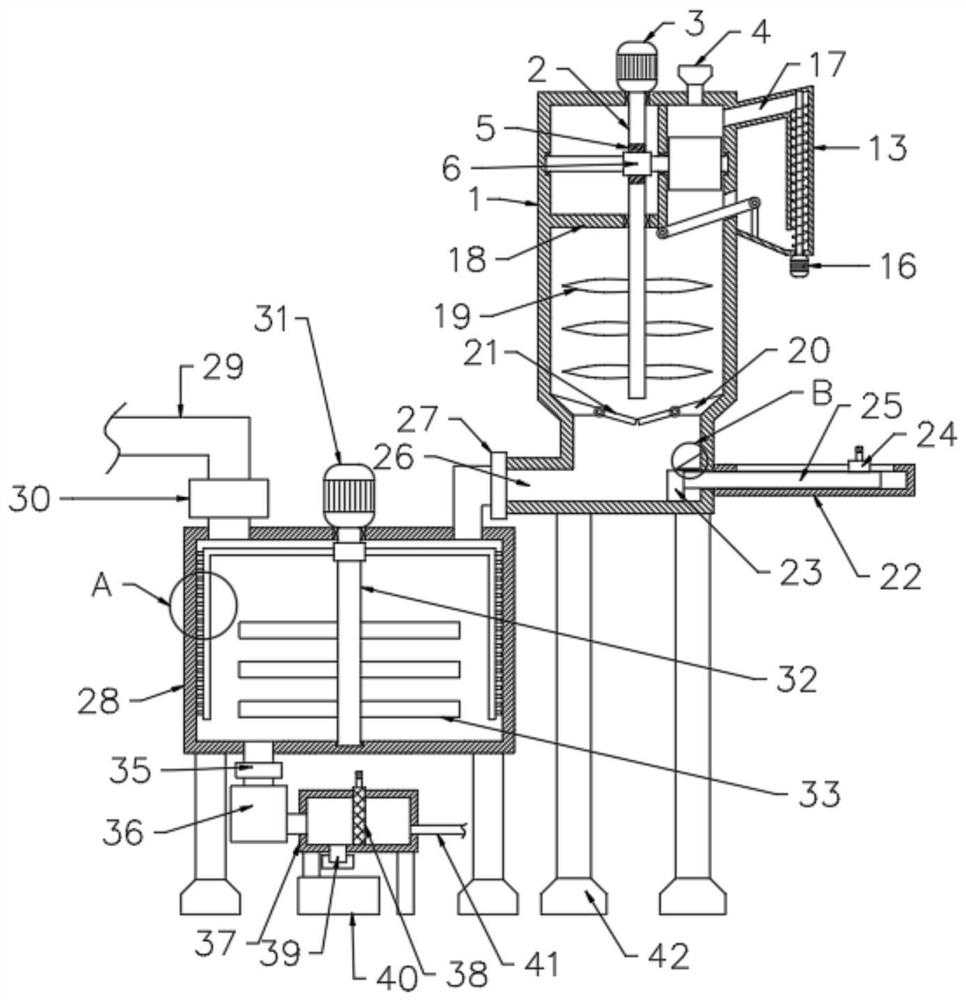

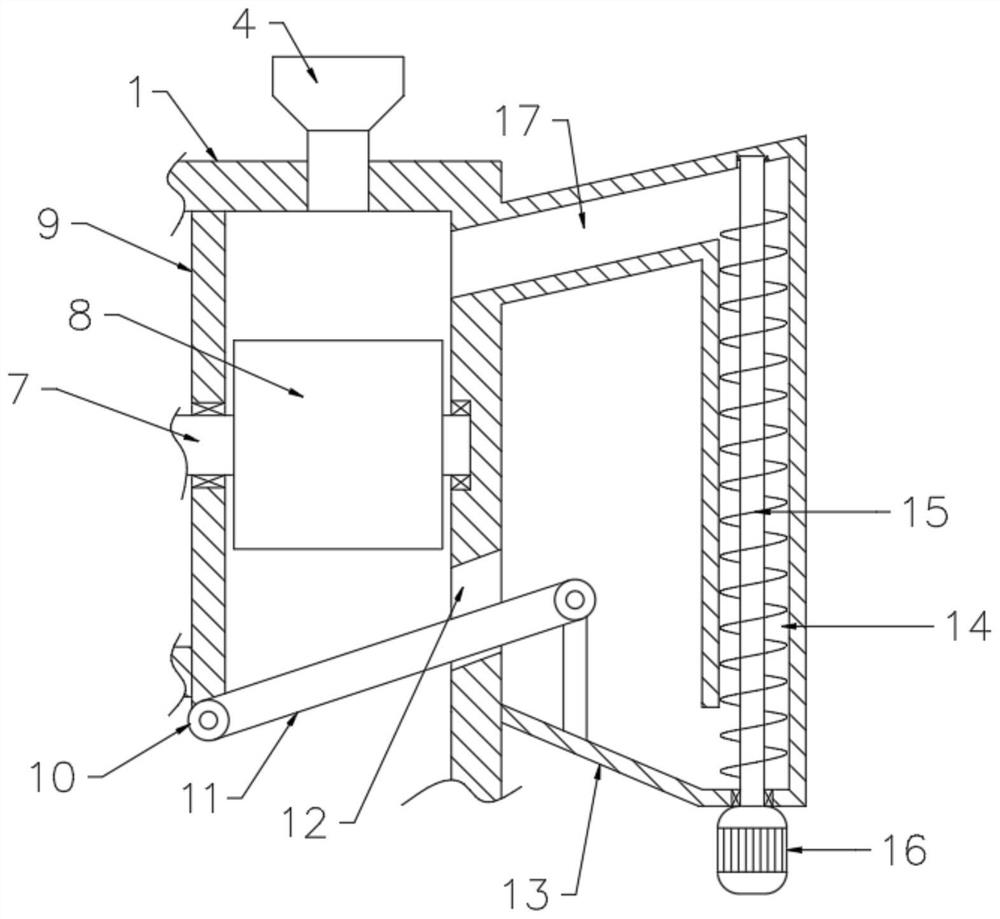

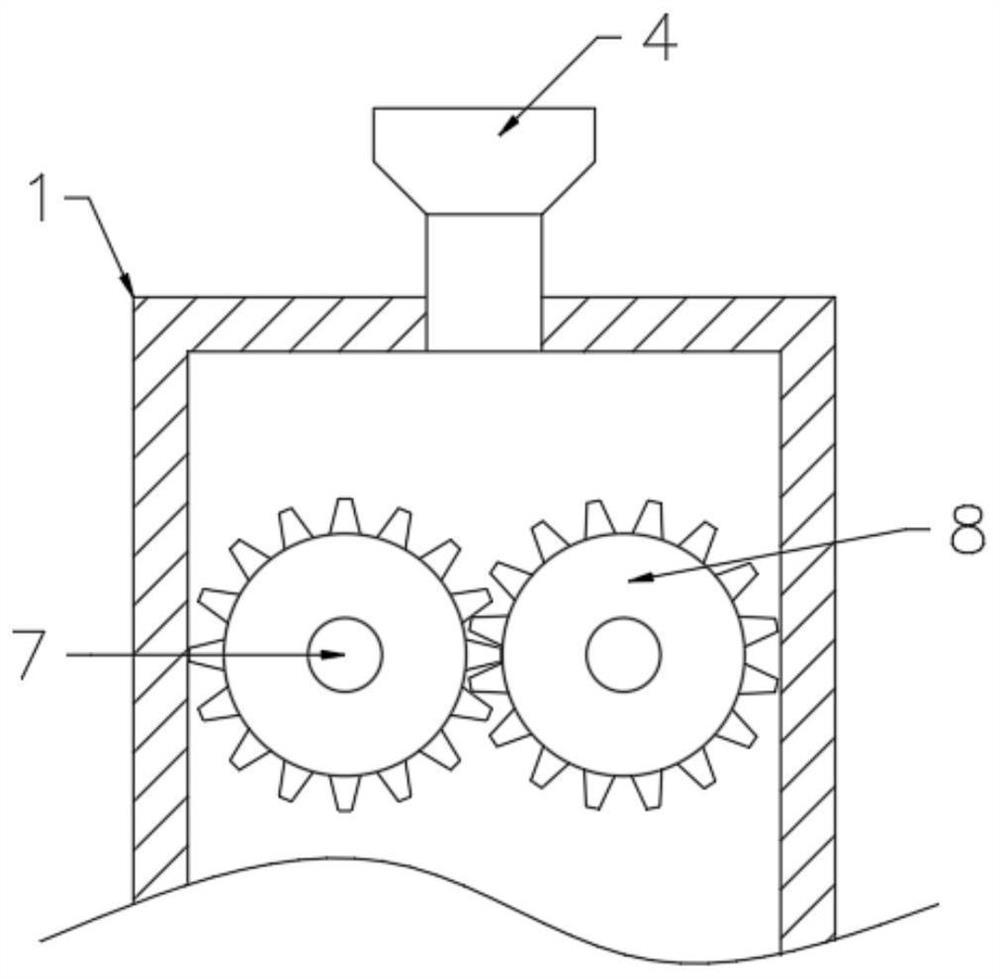

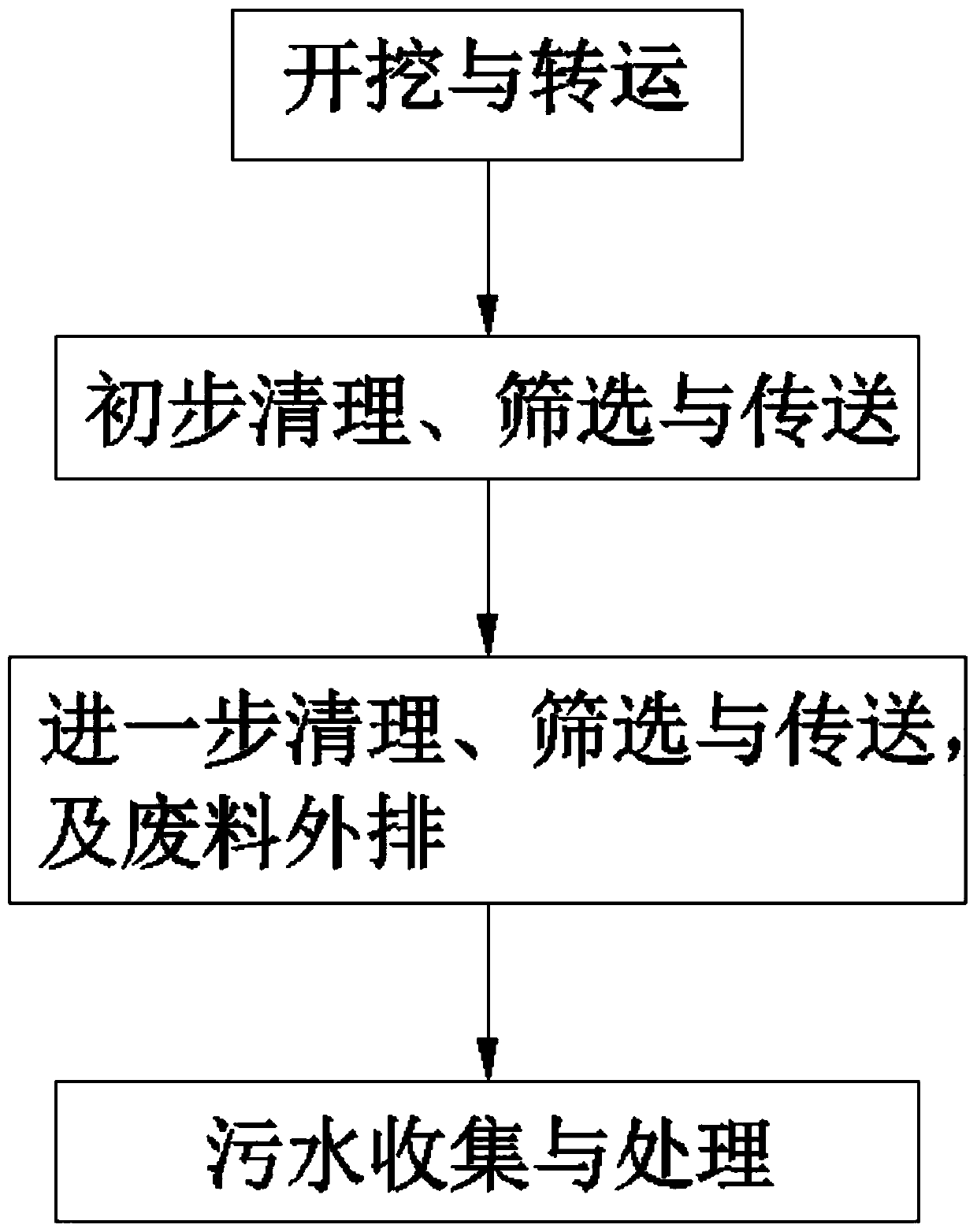

A Restoration Method for Clogged Underflow Constructed Wetland

ActiveCN110713259BEasy to control the feeding speedReduce pollutionSievingScreeningConstructed wetlandSewage

The invention discloses a method for repairing a blocked underflow artificial wetland, which belongs to the technical field of water treatment. The repair method includes the following steps: step S1, excavation and transfer; step S2, preliminary cleaning, screening and transmission; step S3, further cleaning , screening and transmission, and waste discharge; step S4, sewage collection and treatment, the present invention can effectively repair the blocked subsurface flow constructed wetland, and solve the problem that the subsurface flow constructed wetland is easily affected by the blockage of the surrounding environment.

Owner:湖南润万环保科技有限公司

An anti-blocking feed hopper for insulating board production that is convenient for controlling the feeding speed

ActiveCN110371702BNo cloggingEasy to control the feeding speedLarge containersLoading/unloadingElectric machineStructural engineering

Owner:盐城市华科电子有限公司

Adjustable phosphate dosing device

InactiveCN113415906AEasy to control the feeding speedEase of Control UsabilityTransportation and packagingRotary stirring mixersPhosphateEngineering

The invention discloses an adjustable phosphate dosing device and belongs to the technical field of incrustation treatment. The device comprises a dosing box; a rotating shaft and a stirring knife are arranged in the dosing box; a first motor and a feed hopper are arranged on the upper part of the dosing box; a first valve and a pushing assembly of a discharge hole are arranged on the lower part of the dosing box; a water boiling box is arranged below the discharge hole; a stirring shaft and a stirring rod are arranged in the water boiling box; a second motor and a water inflow pipe are arranged at the top surface of the water boiling box; and a water pump and a filtering assembly are arranged below the water boiling box. According to the device of the invention, the dosing box is arranged, phosphate enters the dosing box from the feed hopper, the first motor is started to drive the rotating shaft to rotate, so that the stirring knife is driven to stir materials, the materials are prevented from being stacked together, and the reaction efficiency of the materials and hot water is reduced; the first valve is opened, a sliding block is pushed leftwards, a pushing plate and a pushing rod are driven to move leftwards, the discharging speed and the use dosage of the phosphate are conveniently controlled; and the second motor drives the stirring shaft and the stirring rod to rotate, and therefore the reaction rate of the hot water and the phosphate is increased.

Owner:LIANYUNGANG ZHENGHANG ELECTRIC ENERGY CONSERVATION TECH

Restoration method of blocked underflow constructed wetland

ActiveCN110713259AEasy to control the feeding speedReduce pollutionSievingScreeningConstructed wetlandSewage

The invention discloses a restoration method of a blocked subsurface flow constructed wetland, and belongs to the technical field of water treatment, the restoration method comprises the following steps: step S1, excavation and transfer; S2, preliminary cleaning, screening and conveying treatment; S3, further cleaning, screening and conveying treatment, and discharge of the waste; S4, collection and treatment of sewage. According to the method disclosed by the invention, the blocked subsurface flow constructed wetland can be effectively repaired, and the problem that the surrounding environment is easily influenced after the subsurface flow constructed wetland is blocked is solved.

Owner:湖南润万环保科技有限公司

Discharging device for cellulose acetate processing reaction kettle

PendingCN114682162AAvoid cloggingNovel and compact structureFeed devicesChemistryProcess engineering

The invention relates to the technical field of discharging devices of reaction kettles, in particular to a discharging device for a reaction kettle for cellulose acetate processing. In order to solve the problem of blockage caused by excessive materials in a discharging pipe due to the fact that the discharging amount cannot be controlled, the following technical scheme is provided: the reaction kettle comprises a reaction kettle body, a discharging pipe is arranged at the bottom of the reaction kettle body, and a material blocking mechanism is arranged in the discharging pipe; the material blocking mechanism comprises a first material blocking plate and a second material blocking plate. The discharging device is novel and compact in structure, convenient to control the discharging speed of materials entering the discharging pipe, capable of assisting in knocking the outer wall of the discharging pipe, assisting in discharging of the materials in the discharging pipe, improving the discharging function of the discharging pipe and avoiding the situation that the machining efficiency is affected due to blockage, high in automation degree, multipurpose, comprehensive in function and high in practicability. The device is suitable for efficient processing of cellulose acetate and is mainly applied to processing equipment of cellulose acetate.

Owner:中峰化学有限公司

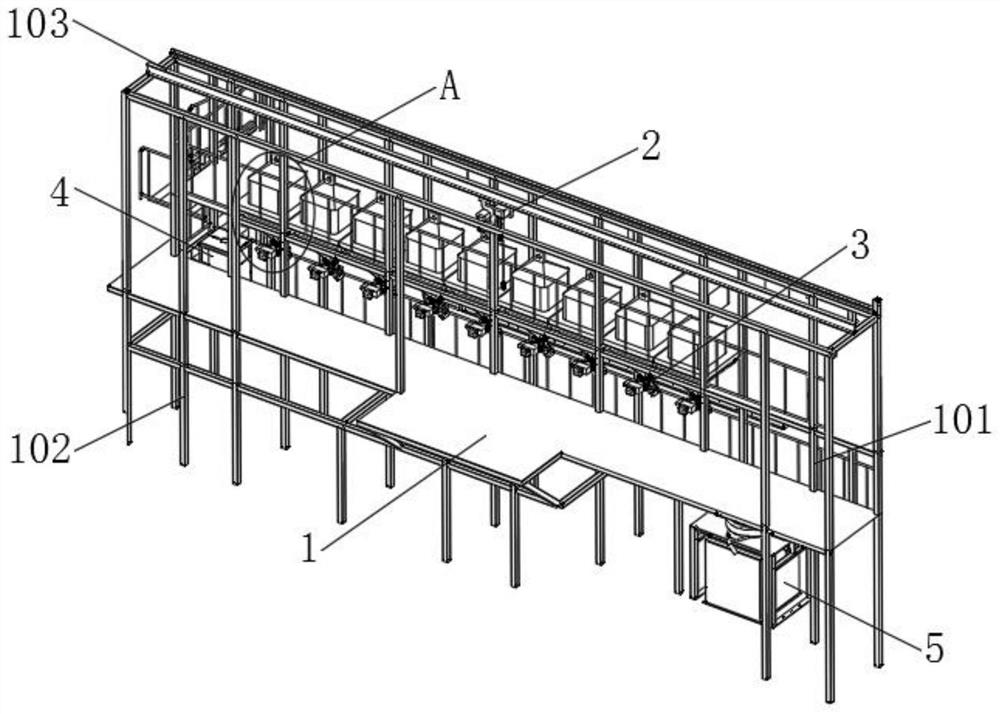

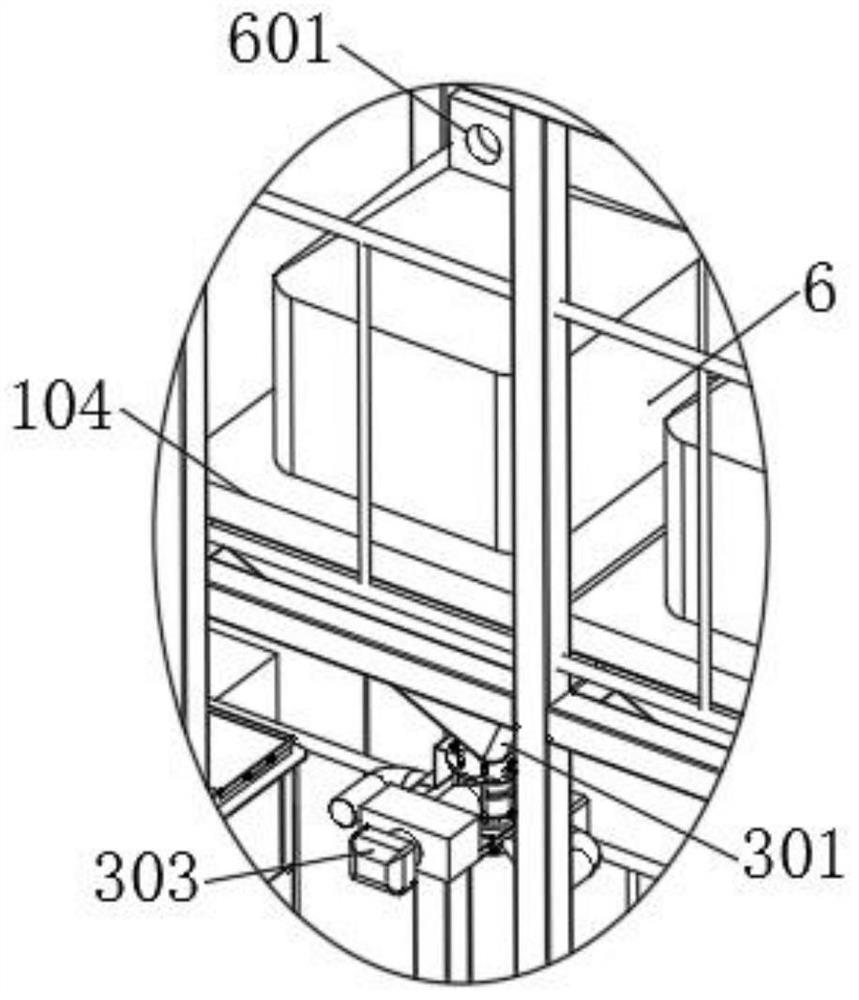

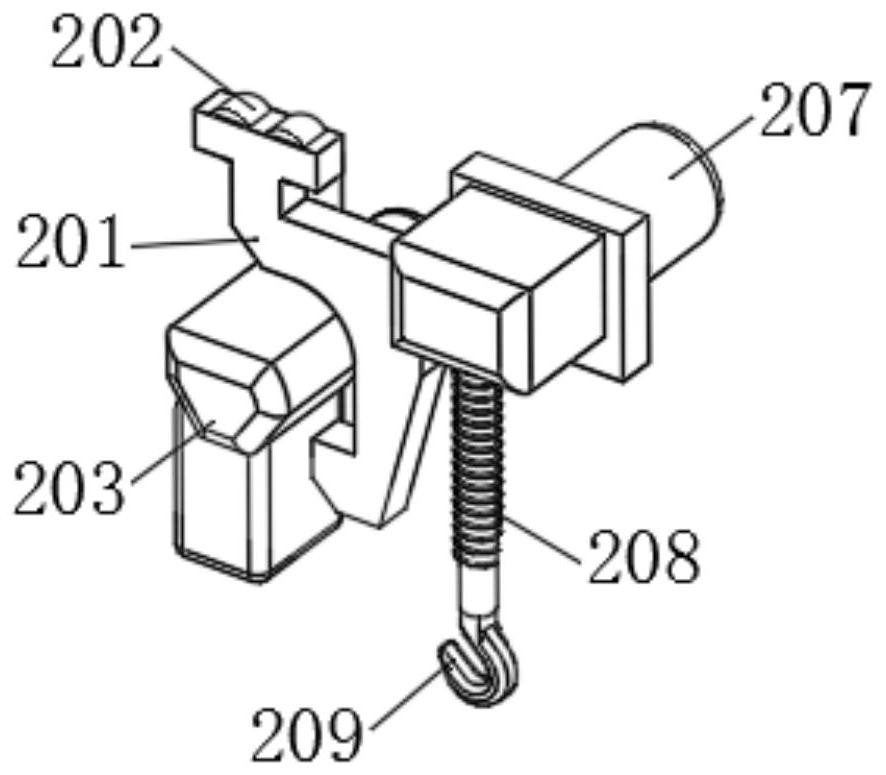

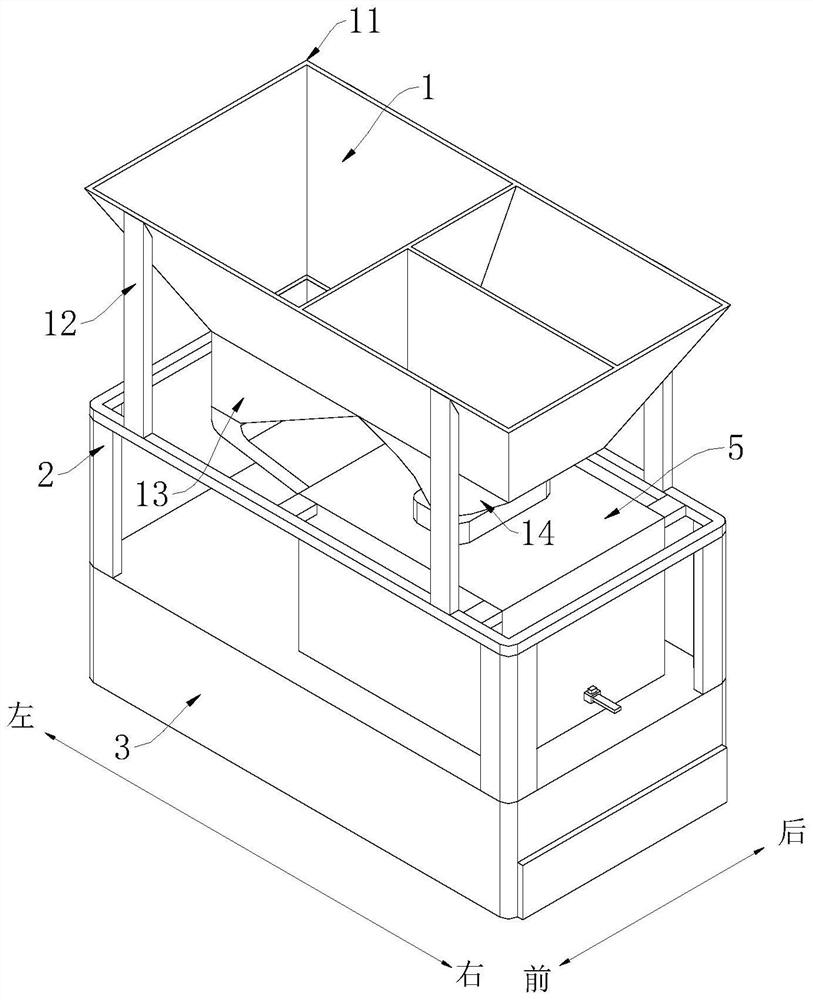

Powder metallurgy die-casting production line

PendingCN114054748AImprove transportation efficiencyShorten production timeProduction lineWorking environment

The invention relates to a powder metallurgy die-casting production line which comprises an operation platform, a supporting frame is installed at the top of the operation platform, a supporting plate is fixed to the top of the supporting frame, a plurality of evenly-distributed placing plates are fixed to the position, close to the middle, of the supporting frame, and a hoisting mechanism used for hoisting materials is arranged at the bottom of the supporting plate. A discharging mechanism for discharging materials is arranged below the placing plate, a driving trolley for transporting the materials is arranged below the discharging mechanism, and a die-casting mechanism for die-casting the materials is arranged below the driving trolley. The problems that an existing powder metallurgy die-casting production line has complex steps for transferring and transporting materials, consequently, the metallurgical production efficiency is low, time and labor are consumed, meanwhile, the working environment is severe due to powder production, the body health of workers is affected, and the efficiency is low due to the fact that demolding is not convenient during die-casting are solved.

Owner:安庆帝新机电设备有限公司

Thermal insulation mortar preparation production line and preparation process

PendingCN114770742AWell mixedFully contactedMixing operation control apparatusCement mixing apparatusThermal insulationProcess engineering

The invention relates to the technical field of mortar production, in particular to a thermal insulation mortar preparation production line and a preparation technology.The thermal insulation mortar preparation production line comprises a supporting frame, a discharging assembly is fixedly connected to the upper surface of the supporting frame, and a stirring assembly is fixedly connected to the lower surface of the supporting frame; a mixing assembly is connected to the position, located in the supporting frame, of the upper surface of the stirring assembly in a penetrating mode, a uniform assembly is rotatably connected to the interior of the mixing assembly, and through arrangement of staggered material guiding plates, solid particle raw materials can roll into the fixing shell in a scattered state after entering the fixing shell; a large amount of solid particles are prevented from entering the interior of the fixed shell in a clustered manner, so that the raw materials are more conveniently mixed, and meanwhile, the raw materials can be better adhered to powder raw materials and additives which fall after being raised in a rolling process; and meanwhile, in the rolling process of the solid particles, powder raw materials and additives can be adhered to all surfaces of the solid particles.

Owner:山东正强新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com