Adjustable phosphate dosing device

A technology of dosing device and phosphate, which is applied to mixers with rotating stirring devices, fixed filter element filters, special treatment targets, etc. It can solve the problem of affecting the scale treatment effect in the boiler and the inability to control the phosphate supply well. To improve the efficiency and stability of the operation and speed up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

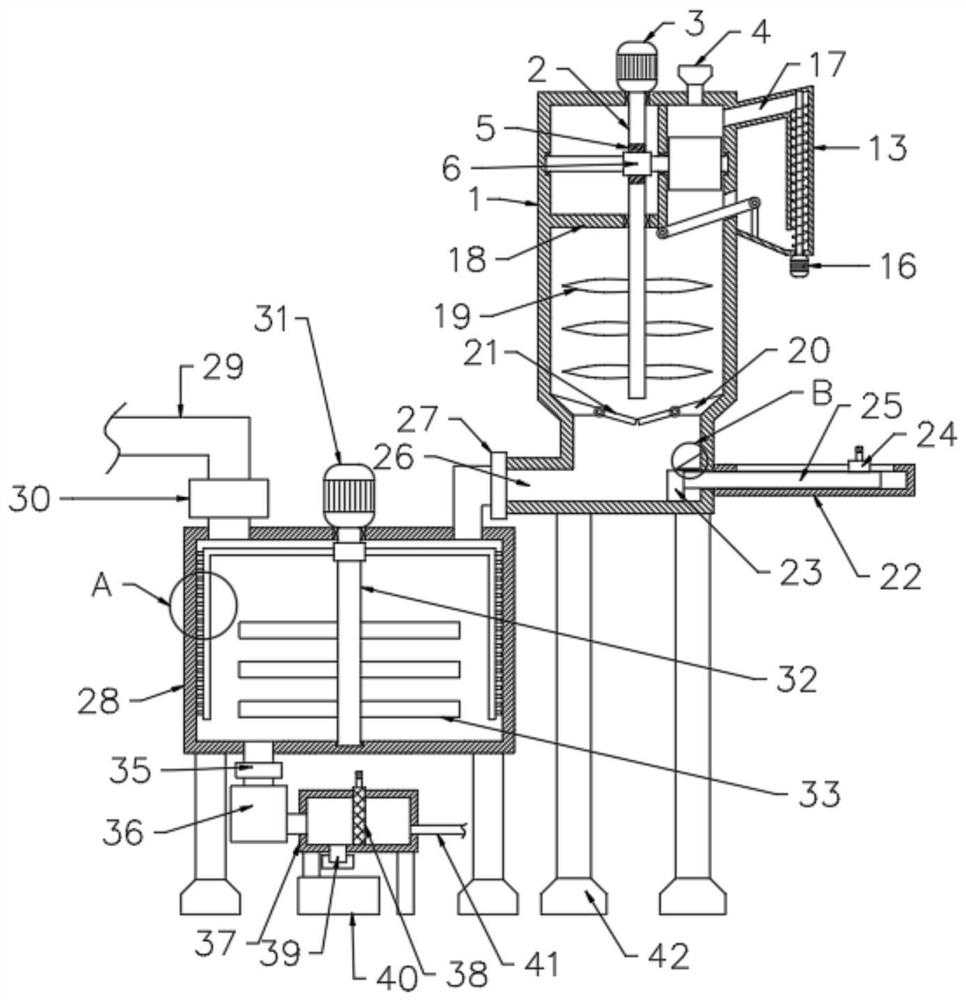

[0034] Please refer to the accompanying drawings, the present invention provides a technical solution: an adjustable phosphate dosing device, comprising a dosing box 1 and a boiling water tank 28, the inside of the dosing box 1 is rotatably connected with a rotating shaft 2, and the rotating shaft 2 The top of the dosing box 1 protrudes, and a No. 1 motor 3 is fixed, and a number of stirring knives 19 are fixed at the lower part. The upper right side of the dosing box 1 is connected with a feed hopper 4, and the lower part of the dosing box 1 is connected with a discharge port. 26. A boiling water tank 28 is connected to the left side of the discharge port 26, a No. 1 valve 27 is provided on the left side of the discharge port 26, and a pusher assembly is provided on the right side;

[0035] The inside of the boiling water tank 28 is rotatably connected with a stirring shaft 32, and the top of the stirring shaft 32 protrudes from the boiling water tank 28, and is fixed with a N...

Embodiment 2

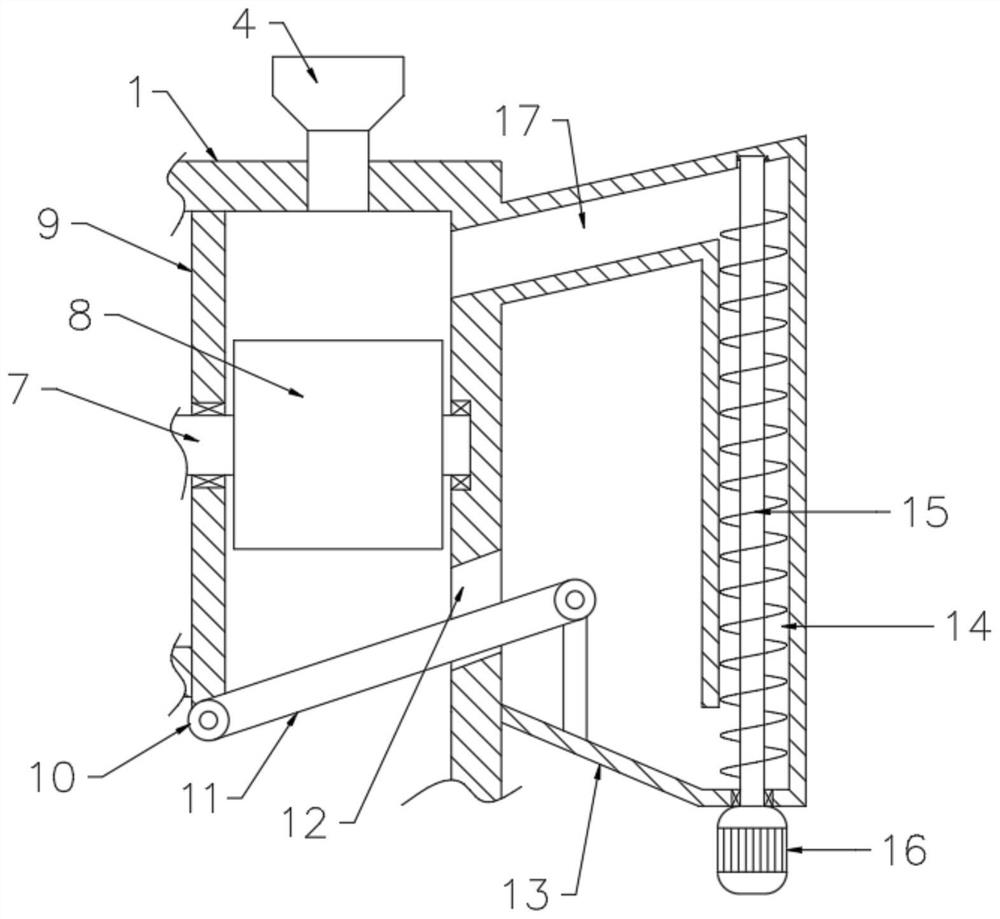

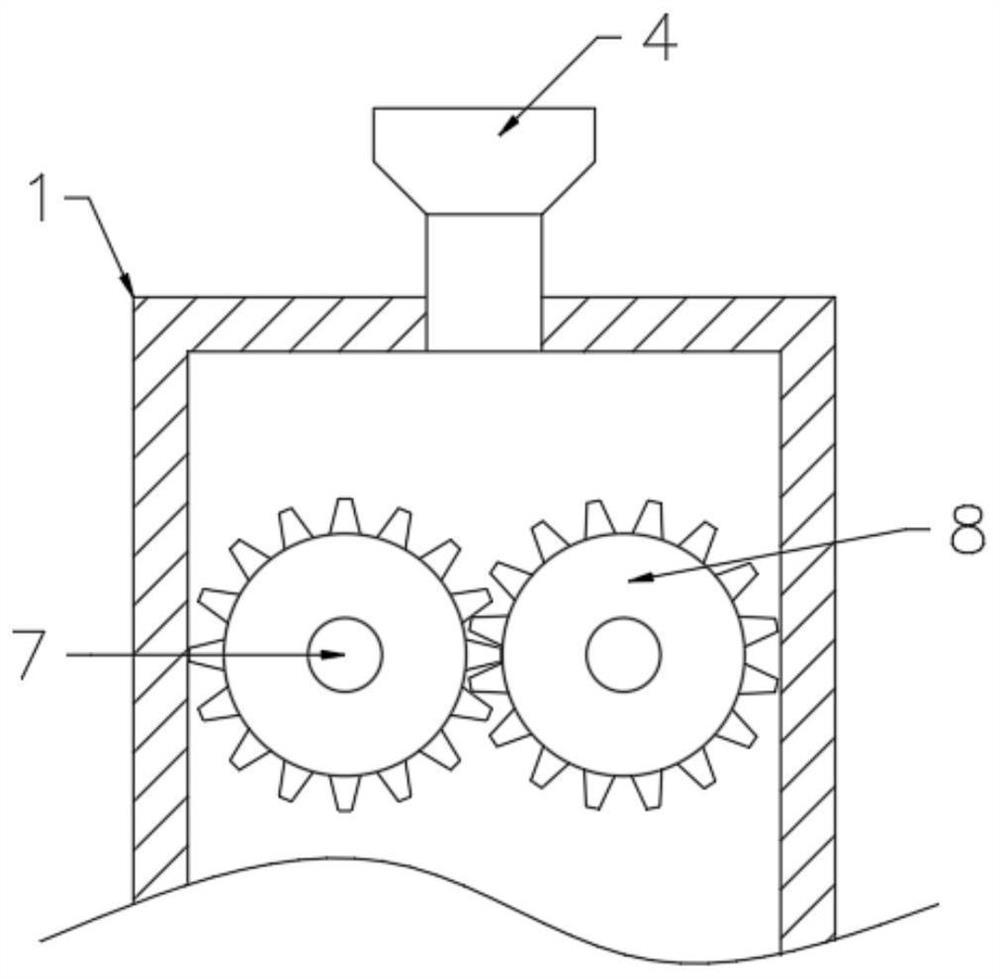

[0046] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a crushing assembly is provided in the dosing box 1, and the crushing assembly includes a vertical plate 9, and the vertical plate 9 is fixed on the middle right of the top surface of the dosing box 1, The left side of the bottom of the vertical plate 9 is also fixed with a horizontal plate 18, and the top of the dosing box 1 is also rotatably connected with two symmetrical rotating shafts 7, and the two rotating shafts 7 are respectively positioned at the front and rear sides of the rotating shaft 2, and the rotating shaft On the 7, the worm gear 6 is fixed on the corresponding rotating shaft 2, and the corresponding worm gear 6 on the rotating shaft 7 is provided with a worm screw 5 meshed with it. The bottom end is rotatably connected with a pulley 10, and the upper right side of the dosing box 1 is provided with a side box 13, and the inside of the side box 13 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com