Discharging device for cellulose acetate processing reaction kettle

A technology of cellulose acetate and reaction kettle, which is applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of excessive material in the discharge pipe, uncontrollable discharge volume, blockage, etc. Achieve the effect of improving the blanking function, novel and compact structure, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

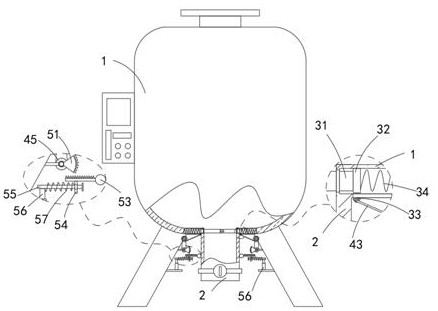

[0029] like Figure 1-5 As shown, the discharge device for the reactor for cellulose acetate processing proposed by the present invention comprises a reactor body 1, the bottom of the reactor body 1 is provided with a support foot, and the bottom of the reactor body 1 is provided with a discharge pipe 2 , a material stopper mechanism 3 is installed in the discharge pipe 2;

[0030] The baffle mechanism 3 includes a baffle plate 31 and a baffle plate 2 35. The sides of the baffle plate 1 31 and the baffle plate 2 35 that are far away from each other are connected with a sliding plate 32, and the bottom inner wall of the reactor body 1 is provided with a sliding cavity. One side of the inner wall of the sliding cavity is fixedly connected with a spring 1 34, the other end of the spring 1 34 is connected with the slide plate 32, one side of the sliding cavity is provided with a plate through hole, and the baffle plate 1 31 and the baffle plate 2 35 respectively penetrate through ...

Embodiment 2

[0035] like Figure 1-5 As shown, the discharge device for a reactor for cellulose acetate processing proposed by the present invention, compared with Embodiment 1, this embodiment also includes a reactor body 1, and a discharge pipe 2 is installed at the bottom of the reactor body 1 , a material stopper mechanism 3 is installed in the discharge pipe 2;

[0036]The blocking mechanism 3 includes a blocking plate 1 31 and a blocking board 2 35, the sides of the blocking board 1 31 and the blocking board 2 35 away from each other are connected with a sliding plate 32, and the bottom of the sliding plate 32 is connected with a guide block 33;

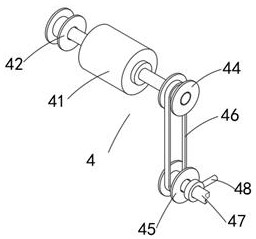

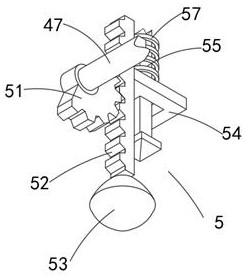

[0037] The two sides of the discharge pipe 2 are provided with a driving mechanism 4. The driving mechanism 4 includes a biaxial motor 41. The output ends of the biaxial motor 41 are respectively connected with a wire take-up pulley 42 and a pulley one 44. The lower part of the pulley one 44 is provided with a The second pulley 45, the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com