Blending device for producing waterborne epoxy anti-rust paint

A water-based epoxy and anti-rust paint technology, used in mixers with rotary stirring devices, mixer accessories, dissolution and other directions, can solve the problems of low mechanical mixing efficiency, poor quality, and heavy manual deployment burden, and achieve ingenious structural design. , Easy to use, stable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

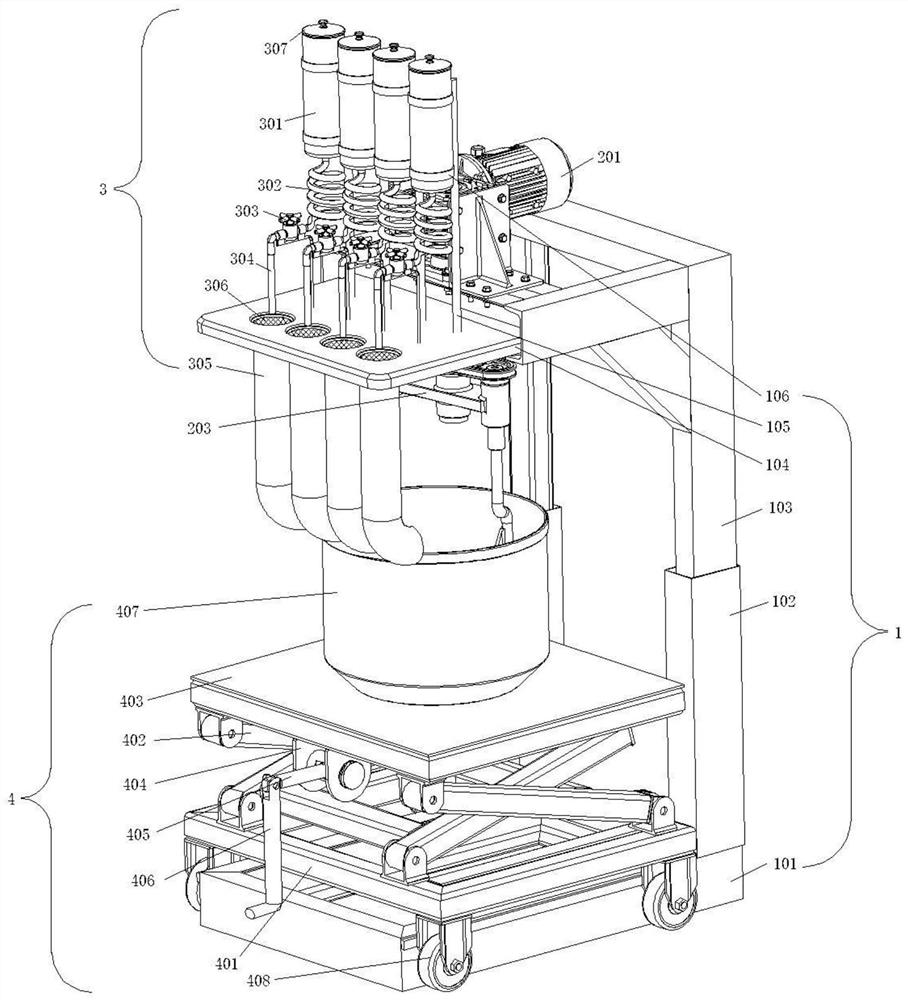

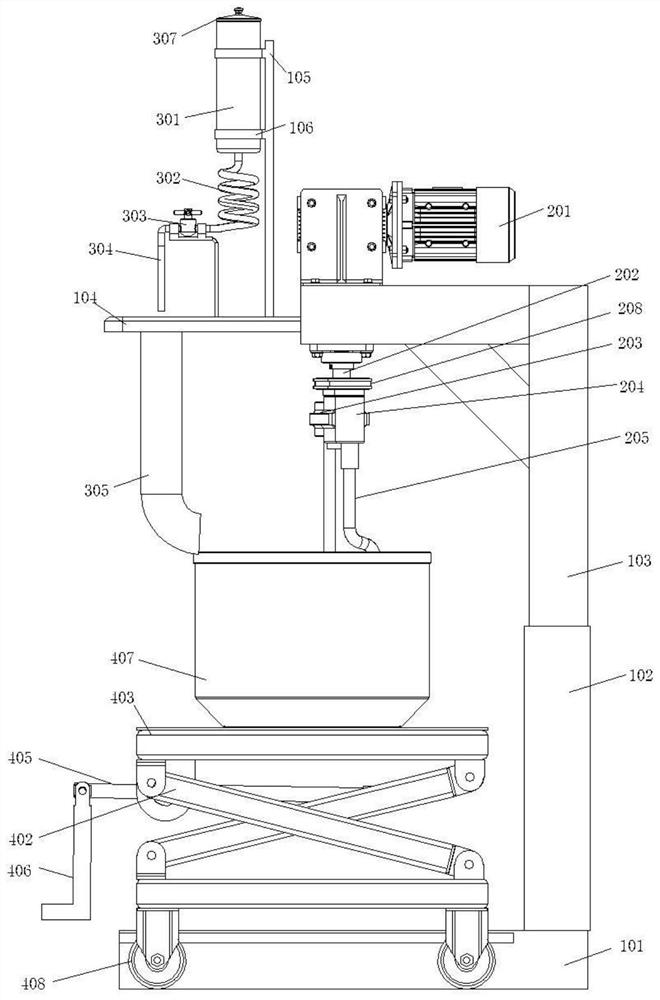

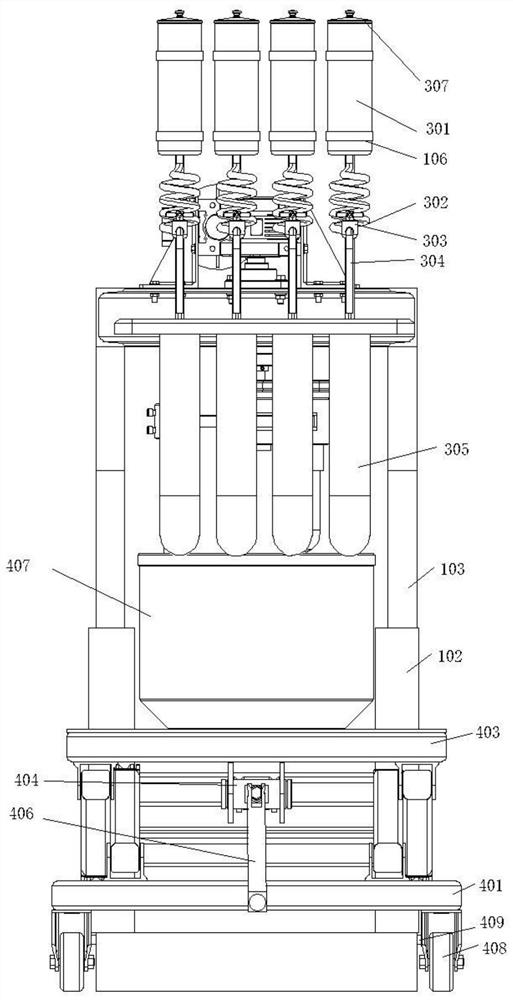

[0032] refer to Figure 1-4 , a water-based epoxy anti-rust paint production deployment device, including a support structure 1, the support structure 1 includes a horizontal base 101, two outer sliding bars 102 fixedly connected with the horizontal base 101, one slidingly connected with the outer sliding bar 102 U-shaped inner slide bar 103, an extension fixed plate 104 fixedly connected with U-shaped inner slide bar 103, a plurality of poles 105 and snap ring 106, the extended fixed plate 104 is equipped with stirring mechanism 2 and blanking control mechanism 3, and The outer side of the horizontal base 101 is slidably connected with a height control mechanism 4. The blanking control mechanism 3 controls the feeding of different materials, and through the cooperation between the stirring mechanism 2 and the height control mechanism 4, the prepared raw materials are fully mixed to ensure Materials are mixed evenly;

[0033] Stirring mechanism 2 comprises motor 201, main rot...

Embodiment 2

[0038] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the diameter of the mixing barrel 407 is greater than the distance between the connecting pipes 305 at both ends, and the connecting pipe 305 does not contact the stirring mechanism 2 during deployment, and the connecting pipe 305 The top is fixedly connected with a filter screen 306.

[0039] In this embodiment, through the relationship between the distance between the connecting pipes 305 and the diameter of the mixing barrel 407 and the positional relationship between the connecting pipe 305 and the stirring mechanism 2, the stability of the feeding process of the device is ensured, and the raw materials are effectively treated by the filter screen 306. Filter to prevent impurities from entering the blending barrel 407 to ensure the blending quality of the water-based epoxy antirust paint.

Embodiment 3

[0041] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bottom of the rotating rod 205 is arranged in an S shape, and its bottom end is obliquely connected to the stirring rotating plate 206, and the stirring rotating plate 206 is opposite to the fixed rotating plate 210 in the direction of inclination. and the same inclination angle.

[0042] In this embodiment, the S-shaped setting at the bottom of the rotating rod 205 increases the radius of the stirring rotating plate 206 when rotating, thereby increasing its multi-directional stirring area, thereby effectively improving the mixing efficiency of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com