An integrated reaction device capable of crushing sieve material

A technology of reaction device and screening material, applied in the field of integrated reaction device capable of crushing and screening material, can solve the problems of falling, loss, complicated operation, etc., and achieve the effect of convenient and full utilization, auxiliary feeding, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

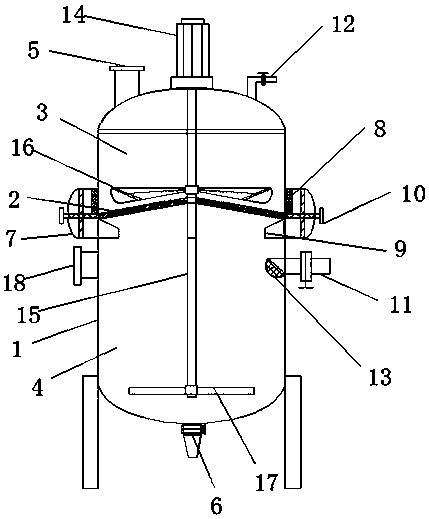

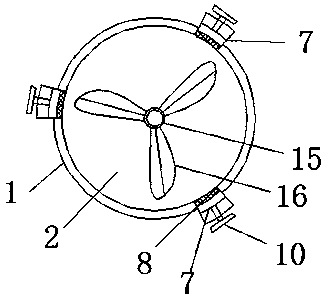

[0015] Embodiment 1: as figure 1 and 2 A kind of integrated reaction device that can pulverize sieve material shown, described reaction device is cylindrical housing 1, and the top of housing 1 is provided with solid feeding port 5 and rotating motor 14, and the bottom of housing 1 is provided with There is a discharge port 6, and the upper part of the housing 1 is provided with a layered partition 2, and the layered partition 2 separates the housing 1 into an upper crushing area 3 and a lower reaction area 4, and the housing 1 There is a stirring shaft 15 connected to the rotating motor 15, the stirring shaft 15 in the reaction zone 4 is provided with a stirring paddle 17, the stirring shaft 15 in the pulverizing zone 3 is provided with a crushing and cutting paddle 16, and the side wall of the housing 1 An arc-shaped airflow lowering chute 7 is arranged on the top, the top of the airflow lowering chute 7 is connected to the crushing area 3 through a screen 8, the bottom of ...

Embodiment 2

[0016] Embodiment 2: as figure 1 and 2 As shown, the layered partition 2 is a conical layered partition raised in the middle; through the conical layered partition 2, it is convenient for the solid particles to directly pass into the screen 8 of the airflow hopper 7 after the crushing structure On, under the action of centrifugal force, gravity and air flow, it assists feeding.

Embodiment 3

[0017] Embodiment 3: as figure 1 and 2 As shown, the top of the pulverizing zone 3 is provided with an auxiliary air supply pipe 12, and the mouth of the auxiliary air extraction pipe 11 in the housing 1 faces downward, and the mouth of the pipe is provided with an arc-shaped material blocking screen 13; through the auxiliary air extraction pipe The combination of 11 and gas pipe 12 assists gas filling from left to right, and the airflow direction in the shell 1 flows from the pulverization zone 3 to the reaction zone 4. The airflow can not only assist feeding, but also avoid the diffusion of products formed by reaction heating in the shell 1 To the crushing zone 3, avoid reaction in the crushing zone 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com