Dust-removal industrial material unloading machine

An unloading machine, an industrial technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of easy consumption, staff hazards, and easy damage of conveyor belts, so as to achieve simple manufacturing process and increase mechanical life , The effect of facilitating the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

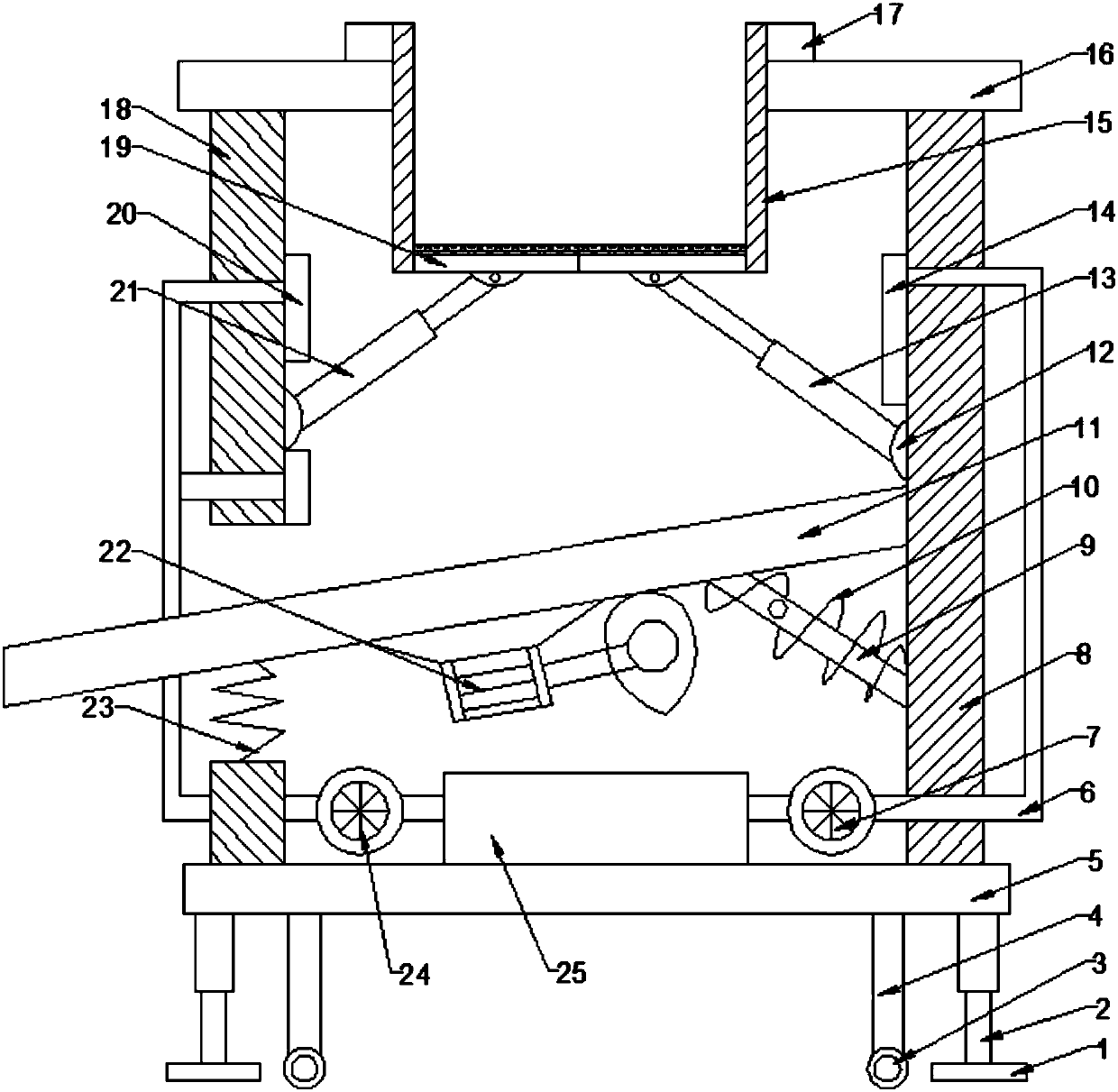

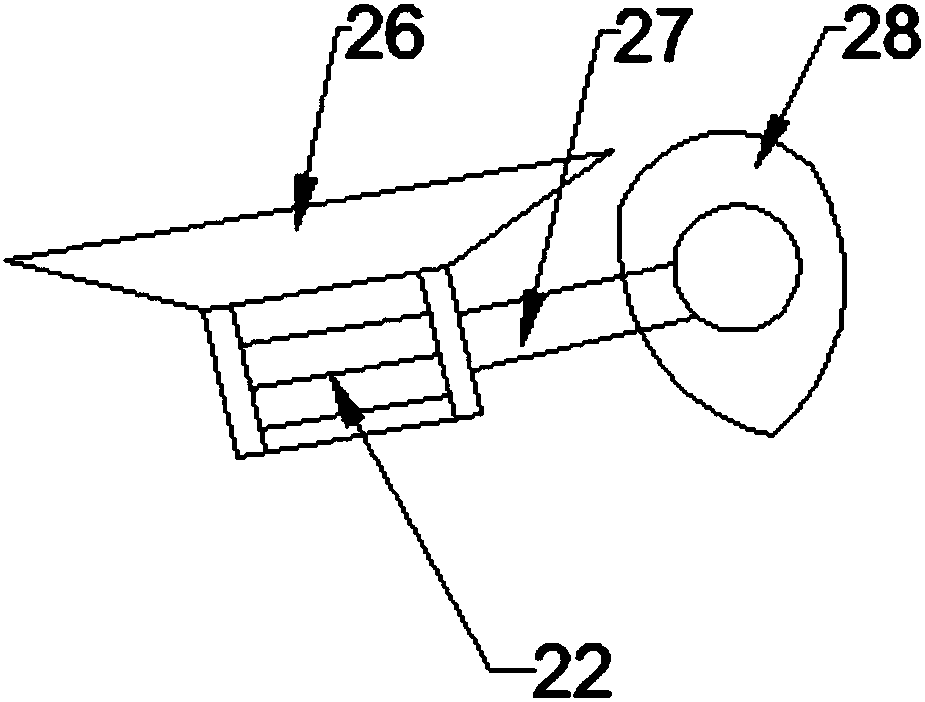

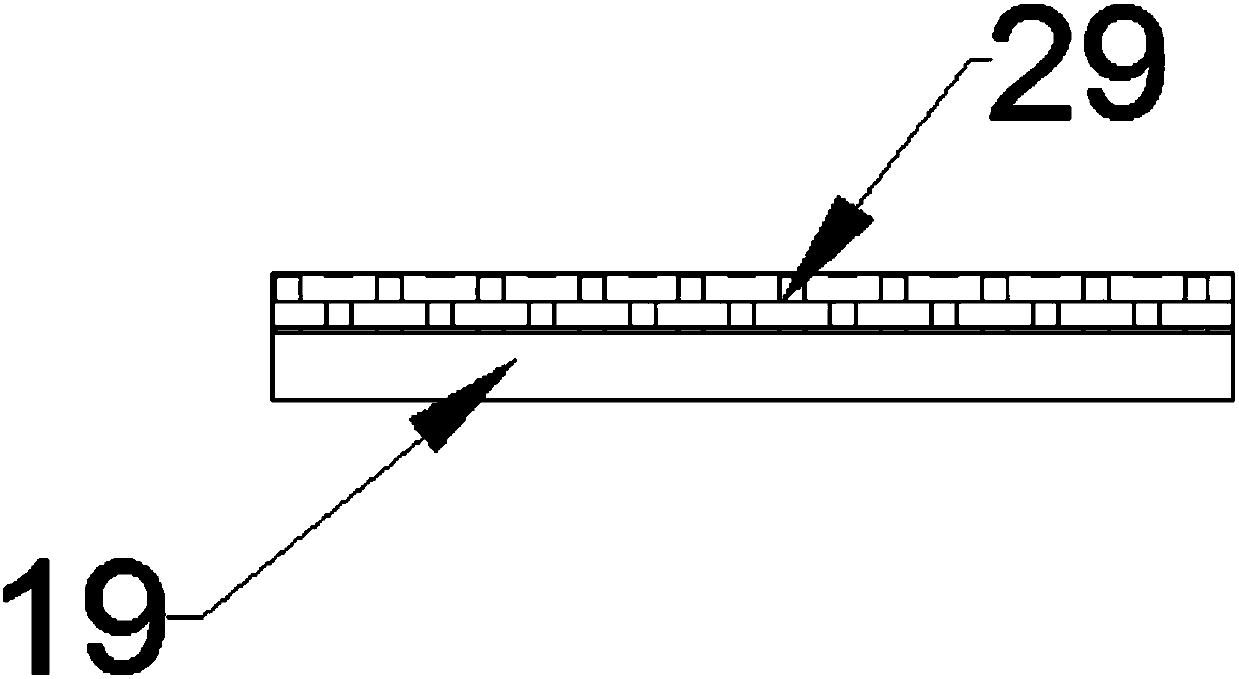

[0017] see Figure 1-3 , a kind of dedusting type industrial material unloading machine, comprising a support device and a discharge device; the support device includes an anchor 1, a hydraulic telescopic column 2, a roller 3, a support column 4 and a bottom plate 5; the support column 4 is set The two sides below the base plate 5 are fixedly connected, and the support column 4 is provided with a roller 3, which has a function of convenient movement; Outer side, the bottom of the hydraulic expansion column 2 is provided with an anchor 1, when working, the anchor 1 is contacted with the ground through the hydraulic expansion column 2, and has the function of maintaining the stability of the device. The discharge device includes a dust suction pipe 6, a second A suction fan 7, right column 8, connecting column 9, damping spring 10, unloading plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com